Device for automatically detecting thickness of sapphire wafer

A sapphire wafer, automatic detection technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low efficiency, unstable quality, and labor-intensive detection, so as to reduce the impact, avoid multiple detections, and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

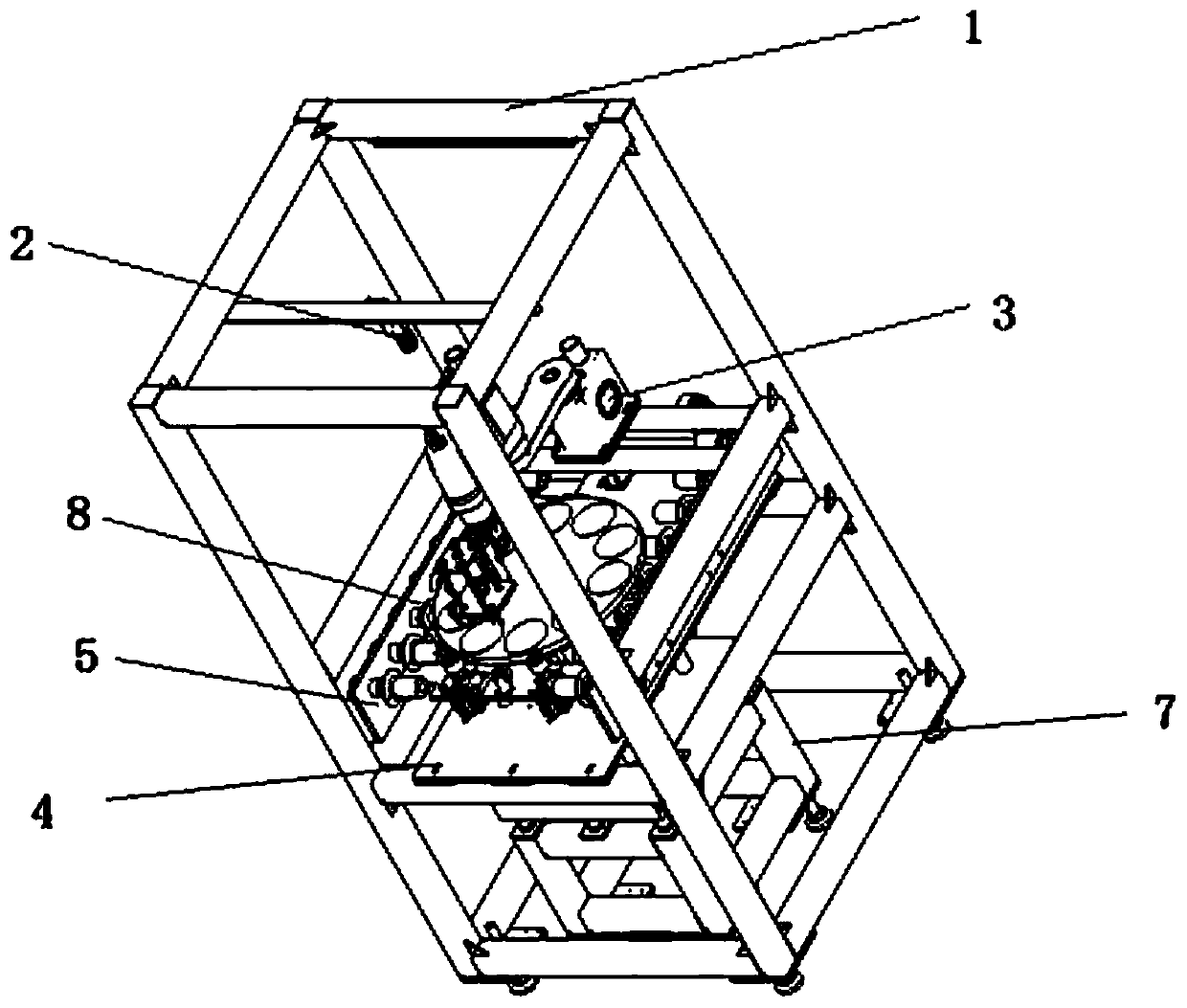

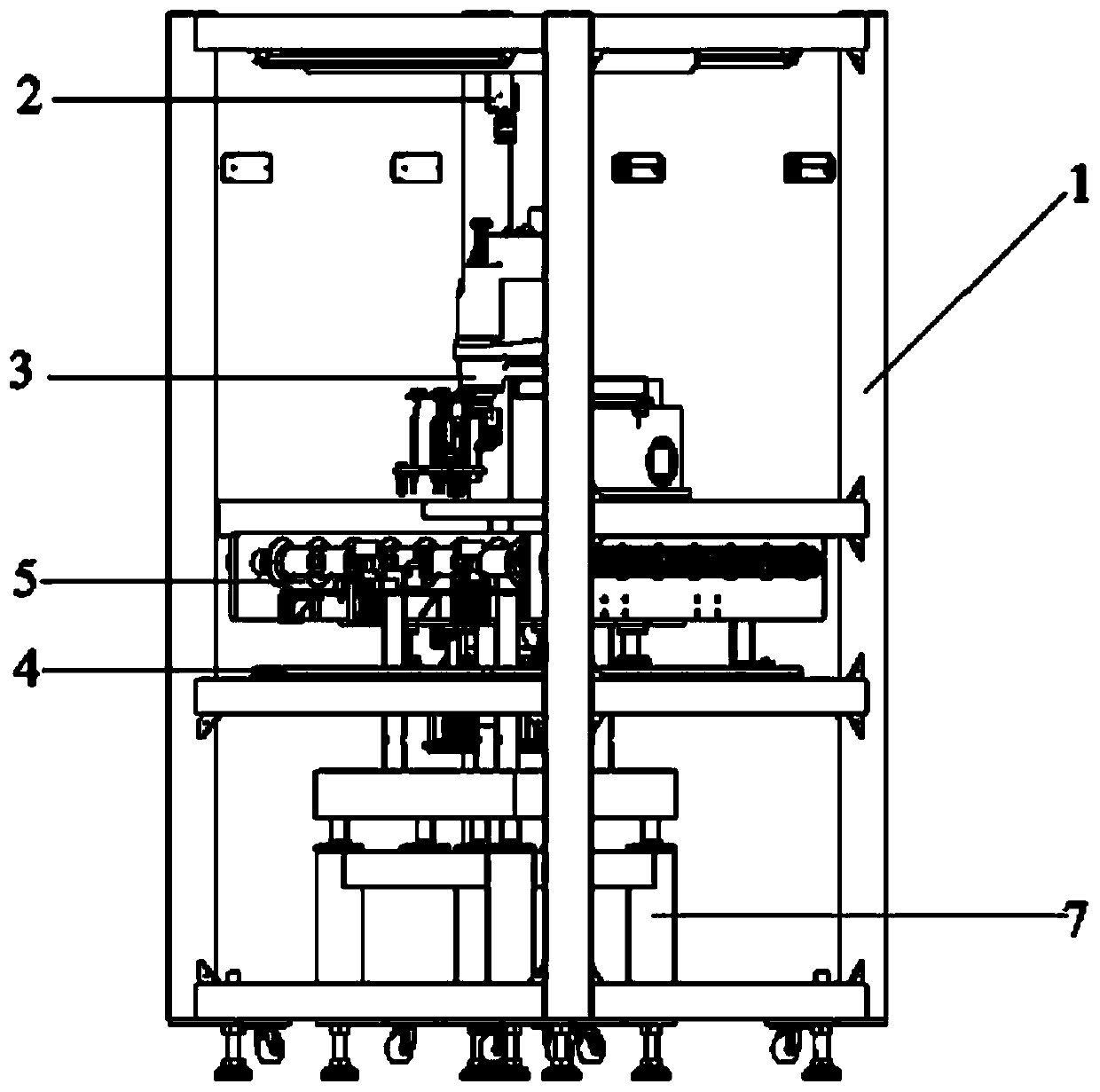

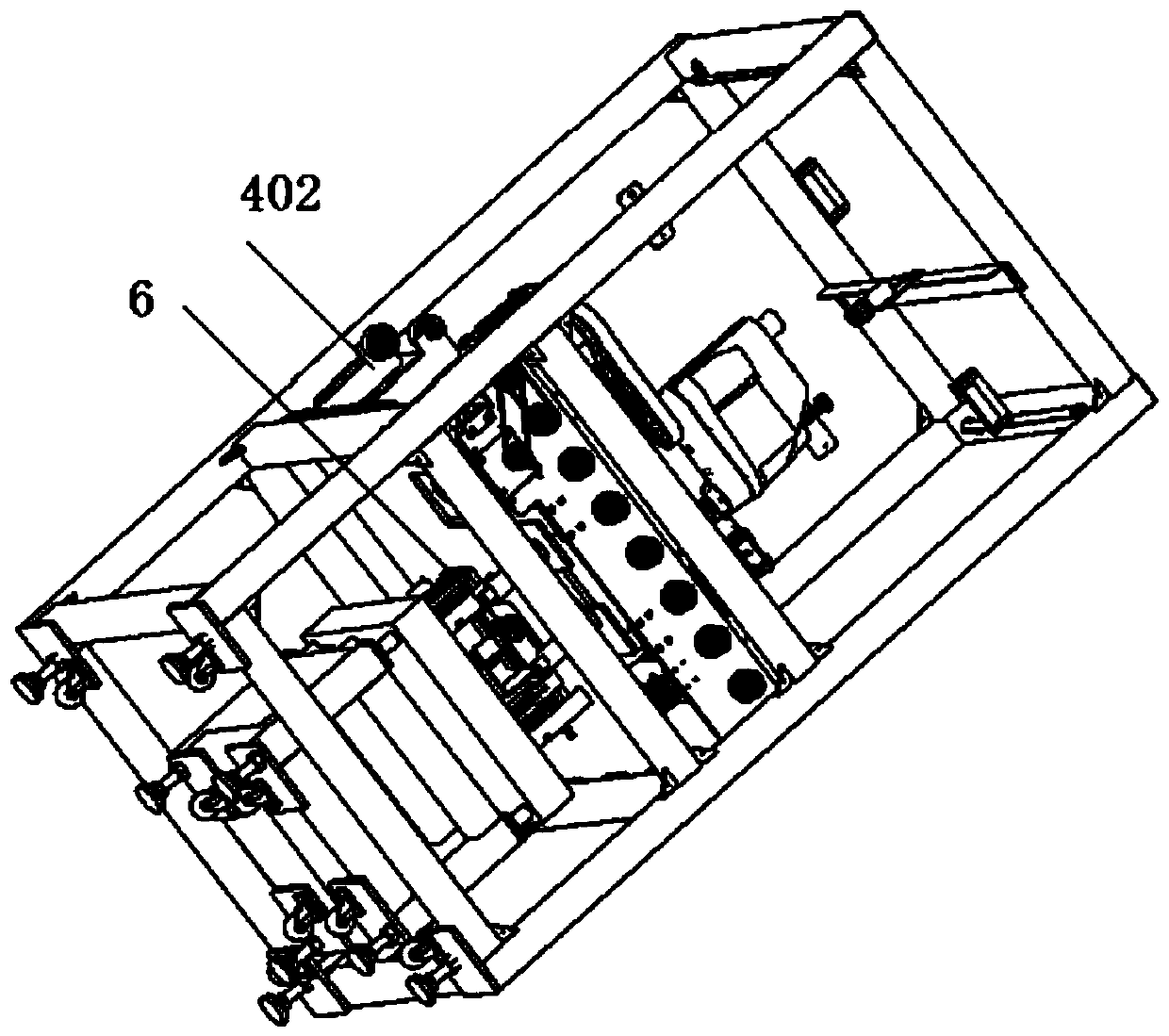

[0039] Such as figure 1 , figure 2 , image 3 A device for automatically detecting the thickness of a sapphire wafer is shown, including a support frame 1, an upper vision device 2, a detection device 3, a guide mounting plate 4, a lifting and conveying device 5, a lower vision device 6, and a marble detection platform 7. The upper visual device 2 , the detection device 3 , the guide mounting plate 4 , the lifting conveying device 5 , and the lower visual device 6 are all located inside the support frame 1 .

[0040] Such as image 3 As shown, the support frame 1 includes a first installation surface 11, a second installation surface 12, and a third installation surface 13 from top to bottom, and the first installation surface 11, the second installation surface 12, and the third installation surface 13 are connected to each other. Through, the first installation surface 11 is located on the top surface of the support frame 1 , the second installation surface 12 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com