A wedge-type pile head and pile-forming construction method for pile side bearing capacity

A pile head and pile side technology, which is applied in the field of hammering steel pile caps and the connection structure between flexible pile caps and prefabricated piles and its construction, to solve the problem of uncoordinated deformation, avoid position deviation, and improve bearing capacity and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

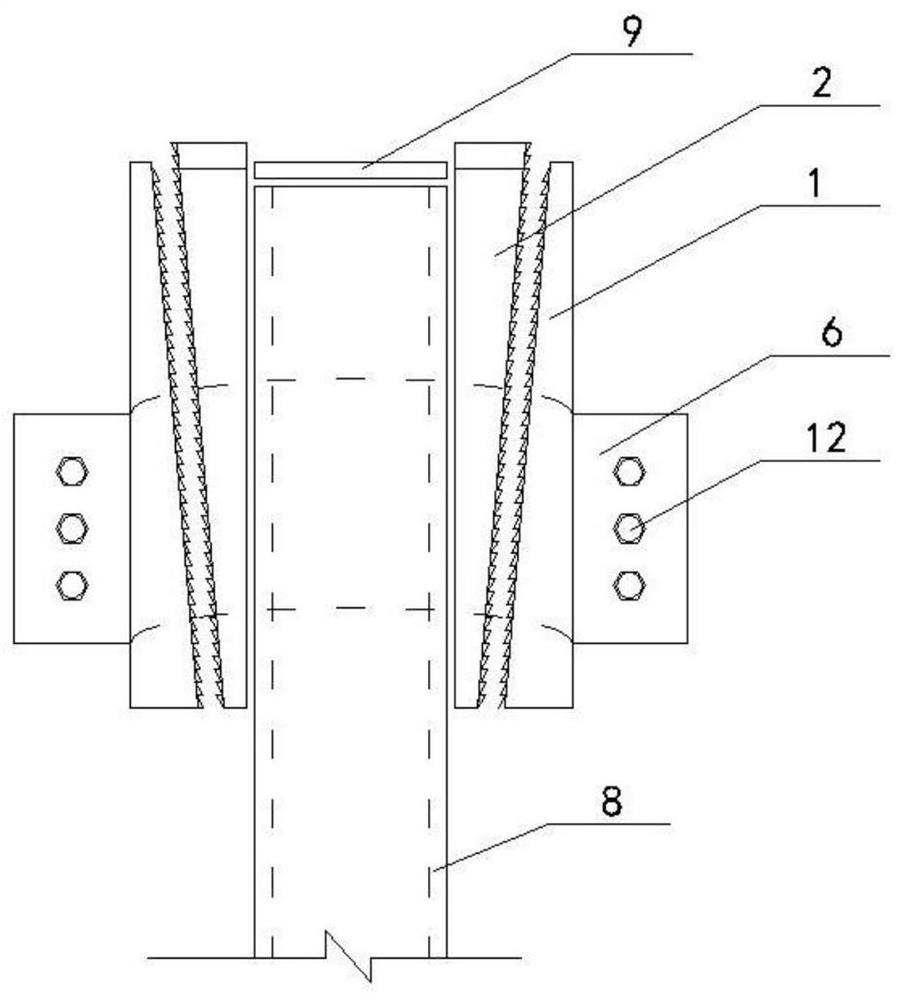

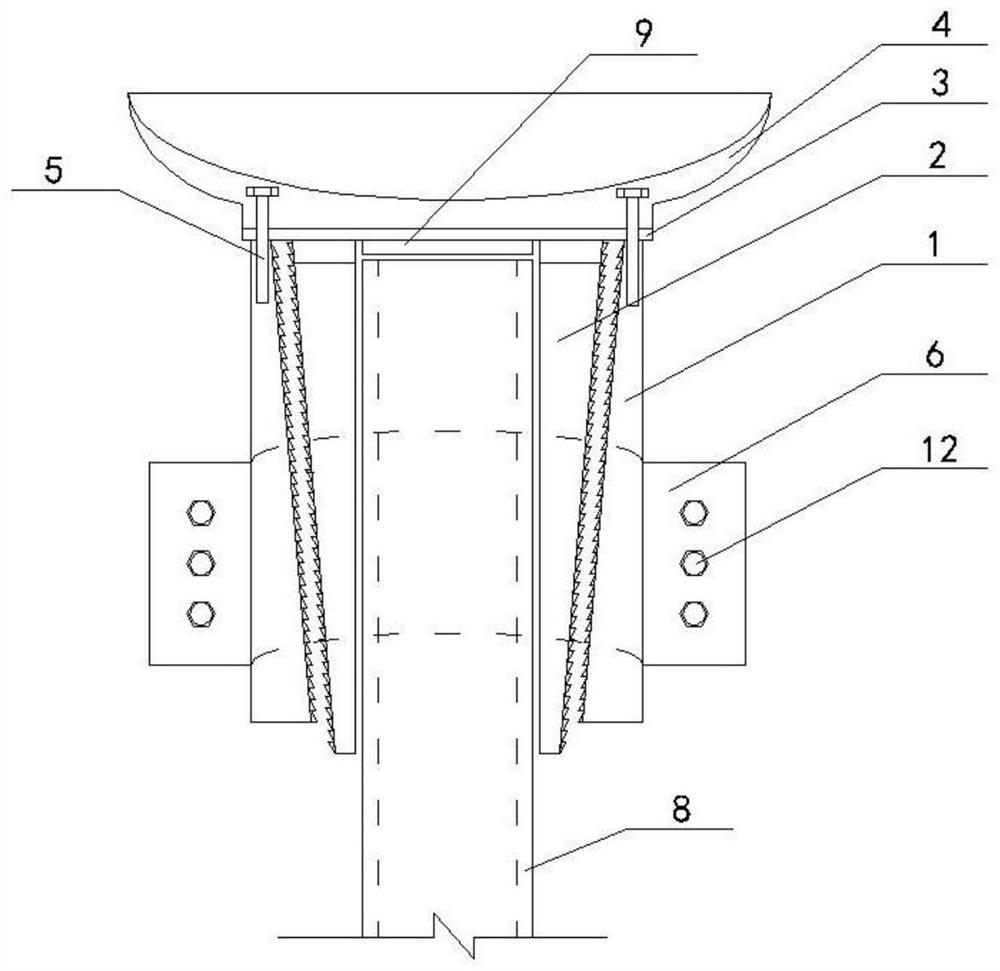

[0025] see figure 1 , the structural form of the wedge-type pile head bearing load on the side of the pile in this embodiment is:

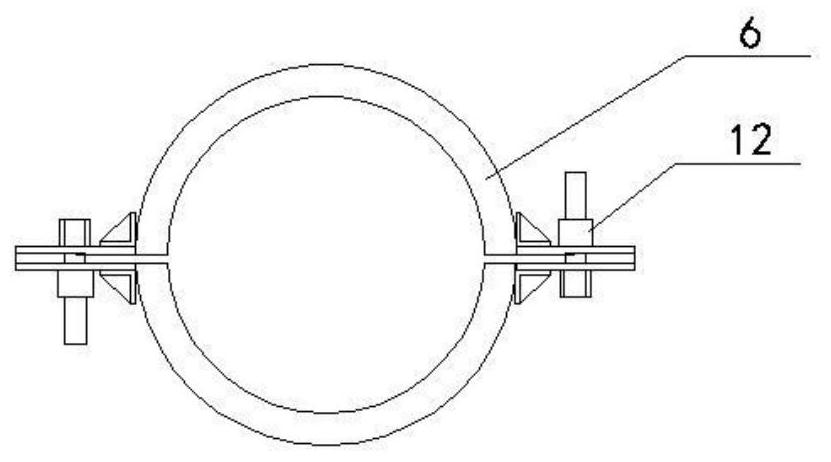

[0026] A tapered outer sleeve 1 is set on the pile head of the pipe pile 8. The inner cavity of the tapered outer sleeve 1 is a tapered cavity, and the diameter of the top surface of the tapered cavity is greater than the diameter of the bottom surface; A cylindrical inner wedge 2 is wedged between the outer sleeves 1 from top to bottom, the inner side wall of the cylindrical inner wedge 2 fits with the smooth wall on the pile side, and the inner side wall of the tapered outer sleeve 1 and The outer wall of the cylindrical inner wedge 2 is meshed with sawtooth; the cylindrical inner wedge 2 can only move downward under the action of the upper load, but not upward, so that the cylindrical inner wedge 2 The wedge wraps the pipe pile head more tightly, and the four cylindrical inner wedges arranged separately form a cone with a cylindrical cavity. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com