A speed-locked self-resetting anti-buckling brace

A technology of anti-buckling support and velocity locking, which is applied in the field of bridge seismic design, and can solve problems such as temperature sub-internal force concrete shrinkage and creep constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

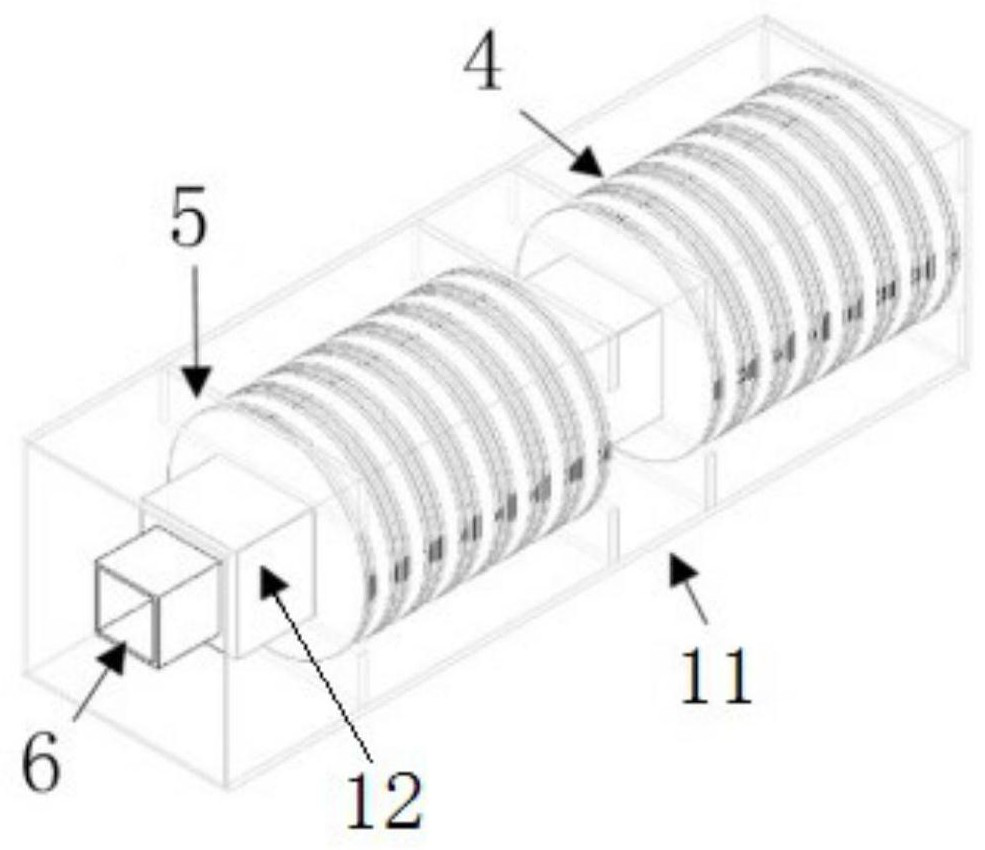

[0045] refer to Figure 14 Specifically explain this embodiment, the speed-locking type self-resetting anti-buckling support described in this embodiment, its specific design, composition and working mode include the following steps:

[0046] Step 1: Complete the composition and combination of the three parts of the speed locking (LU) system, self-resetting (SC) system and buckling-resistant bracing (BRB) system;

[0047] Step 2: Explain the working principle of the device in static state, normal use state and earthquake vibration;

[0048] Step 3: According to the working principle of each part of the system, select the material and design the size;

[0049] Step 4: Using the viscous damper as a prototype to derive the restoring force model of the speed locking device, analyze the restoring force models of the self-resetting system and the anti-buckling system, and explain the combined working model of the three-part system, and the calculation method of the residual deforma...

specific Embodiment approach 2

[0058] This embodiment is a further description of the speed-locked self-resetting anti-buckling support described in the first specific embodiment. The principle is:

[0059] Step 21: The overall structure reaches static equilibrium in static mode;

[0060] Step 2 and 2: In the normal working mode, that is, in the deformation caused by temperature rise and temperature drop, the pier beam produces relative displacement. Since the supporting piston rod arranged at the movable pier can freely enter and exit in the cylinder, the deformation is released and self-resetting and energy-consuming devices are not activated;

[0061] Step 2 and 3: Under the action of the earthquake, the speed locking device quickly switches to the "locked" state, a damping force is generated in the damping hole, the rigidity of the cylinder barrel increases rapidly, and the cylinder barrel drives the casing in the self-resetting system, and the baffle inside the casing The disk spring is driven to mov...

specific Embodiment approach 3

[0063] This embodiment is to carry out the selection of material and the design of size for the working principle of each part system of the device described in the second embodiment. In this embodiment, the selection of materials and the design of the size in Step 3 are as follows: , and different types of bridges have different requirements for device materials under different seismic environments)

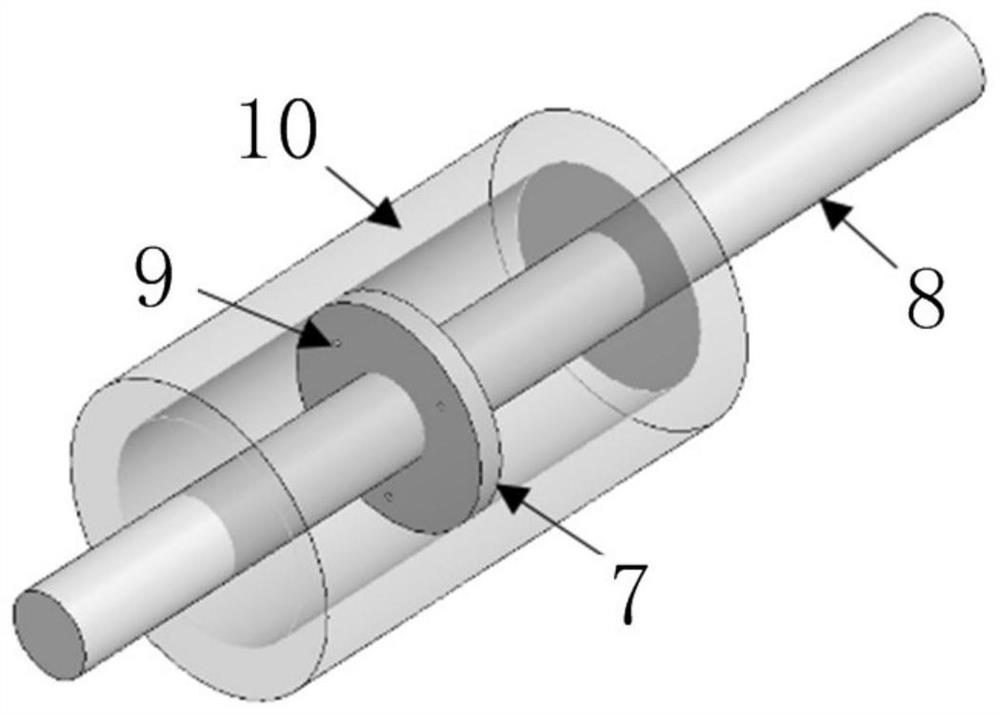

[0064] Step 31: Design of speed lock device:

[0065] According to a large number of quasi-static test results, the viscosity attenuation coefficient m of methyl silicone oil will change with the shear velocity μ, and the relationship between the two is shown in formula (1):

[0066]

[0067] This is also the basis for the calculation of the damping force due to viscous friction.

[0068] This specific implementation plans to adopt a density of 930kg / m 3 , a viscous medium of methyl silicone oil with a kinematic viscosity of 20000cSt.

[0069] The speed locking device ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com