Production method of high-strength steel

A production method and high-strength steel technology, applied in the field of hot rolling technology, can solve the problems of increasing production energy consumption, reducing cold rolling force, and increasing manufacturing cycle, so as to reduce production energy consumption, shorten manufacturing cycle, and shorten manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

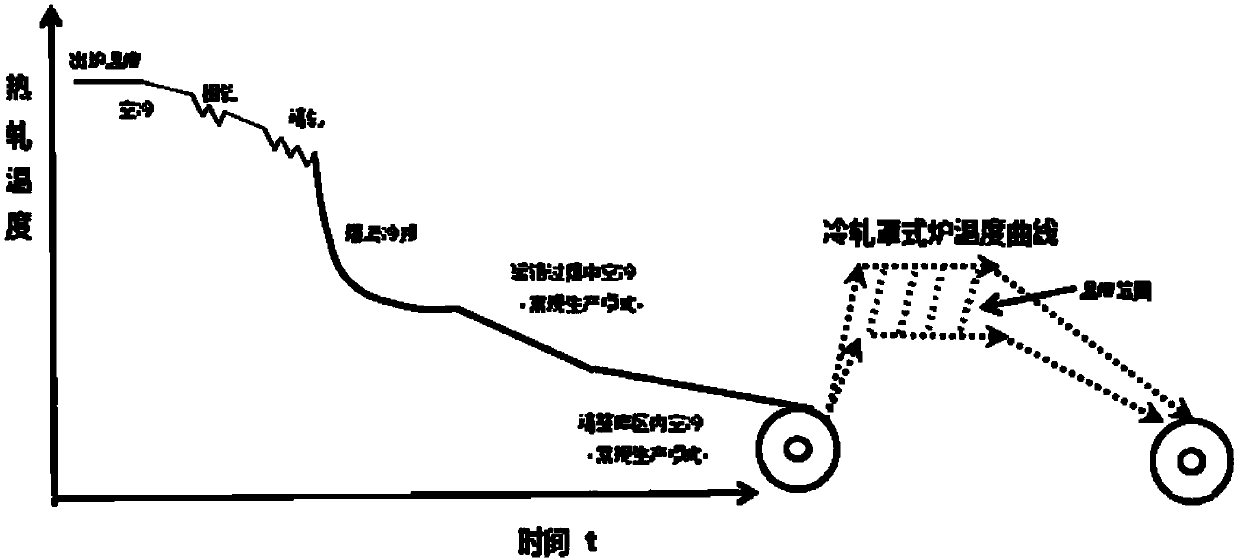

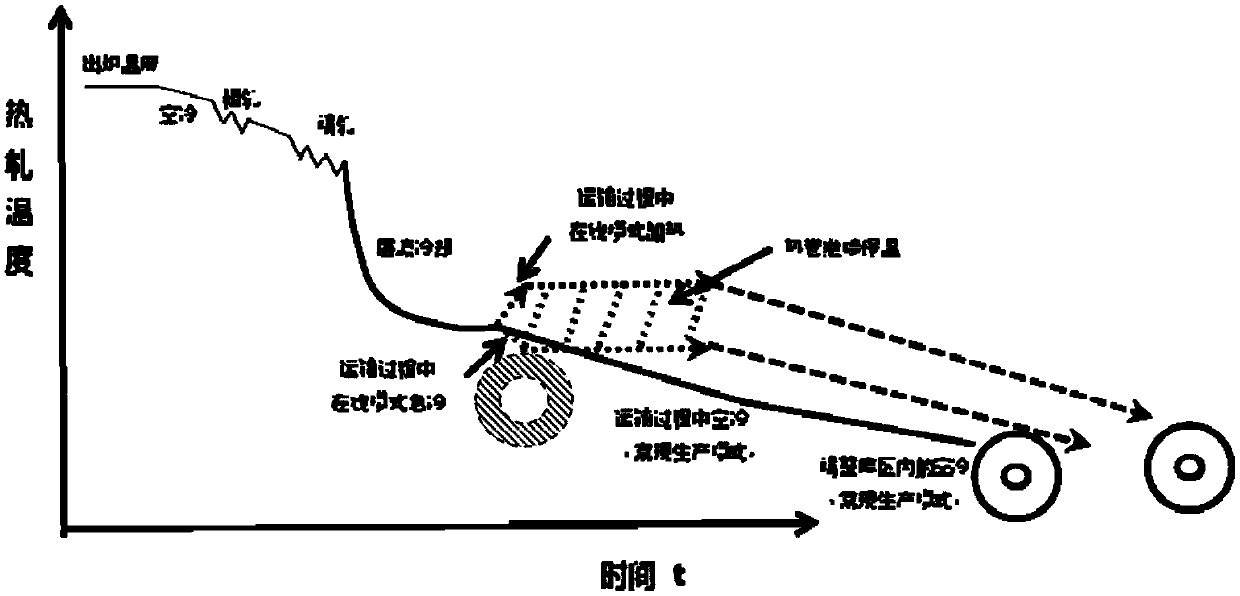

[0016] see figure 2 , a kind of production method of high-strength steel of the present invention, slab is directly sent to cold rolling after hot-rolling, coiling, bundling, on-line heat preservation, obtains high-strength steel cold-rolled sheet through cold rolling; 880~950℃, and the coiling temperature is controlled at 450~700℃; the bundled steel coils are directly transferred to the cold rolling unit through the steel coil transportation chain or the moving trolley. Coils are subjected to online heat preservation or heating treatment, and annealing and tempering are directly completed by using the waste heat of hot coils; the temperature range in the heat preservation cover is 450-680 degrees, and the online heat preservation time is 1 to 24 hours. The steel coil continues to heat up or cool down in the heat preservation cover, and the heat preservation is completed Finally, the steel coil is cooled to room temperature by air cooling and sent to the cold rolling mill.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com