Winding processing method, device and system for inductance coils

A technology for inductance coils and processing systems, applied in coil manufacturing, inductance/transformer/magnet manufacturing, circuits, etc., can solve problems such as low efficiency and achieve the effect of improving winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

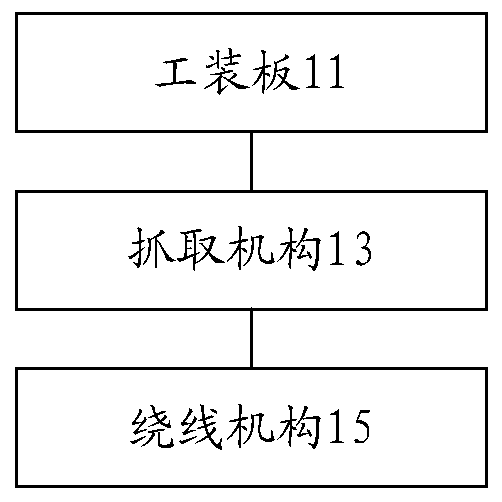

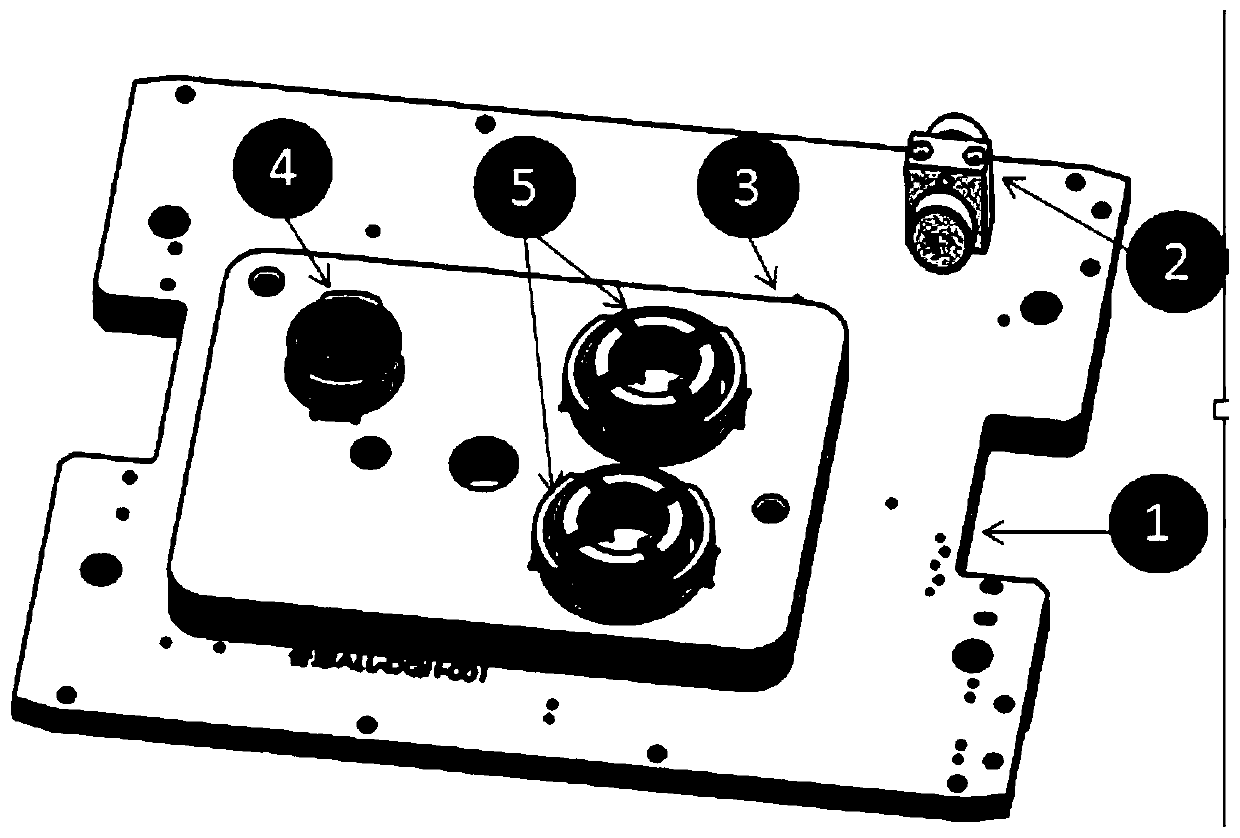

[0029] According to an aspect of an embodiment of the present invention, a winding processing system for an inductor coil is provided, figure 1 It is a schematic diagram of a winding processing system of an inductance coil according to an embodiment of the present invention, such as figure 1 As shown, the winding processing system of the inductor coil includes: a tooling plate 11 , a grabbing mechanism 13 , and a winding mechanism 15 . The winding processing system of the inductor coil will be described in detail below.

[0030] The tooling board 11 is used for positioning the inductance coil to be wound, and transporting the positioned inductance coil to the winding station.

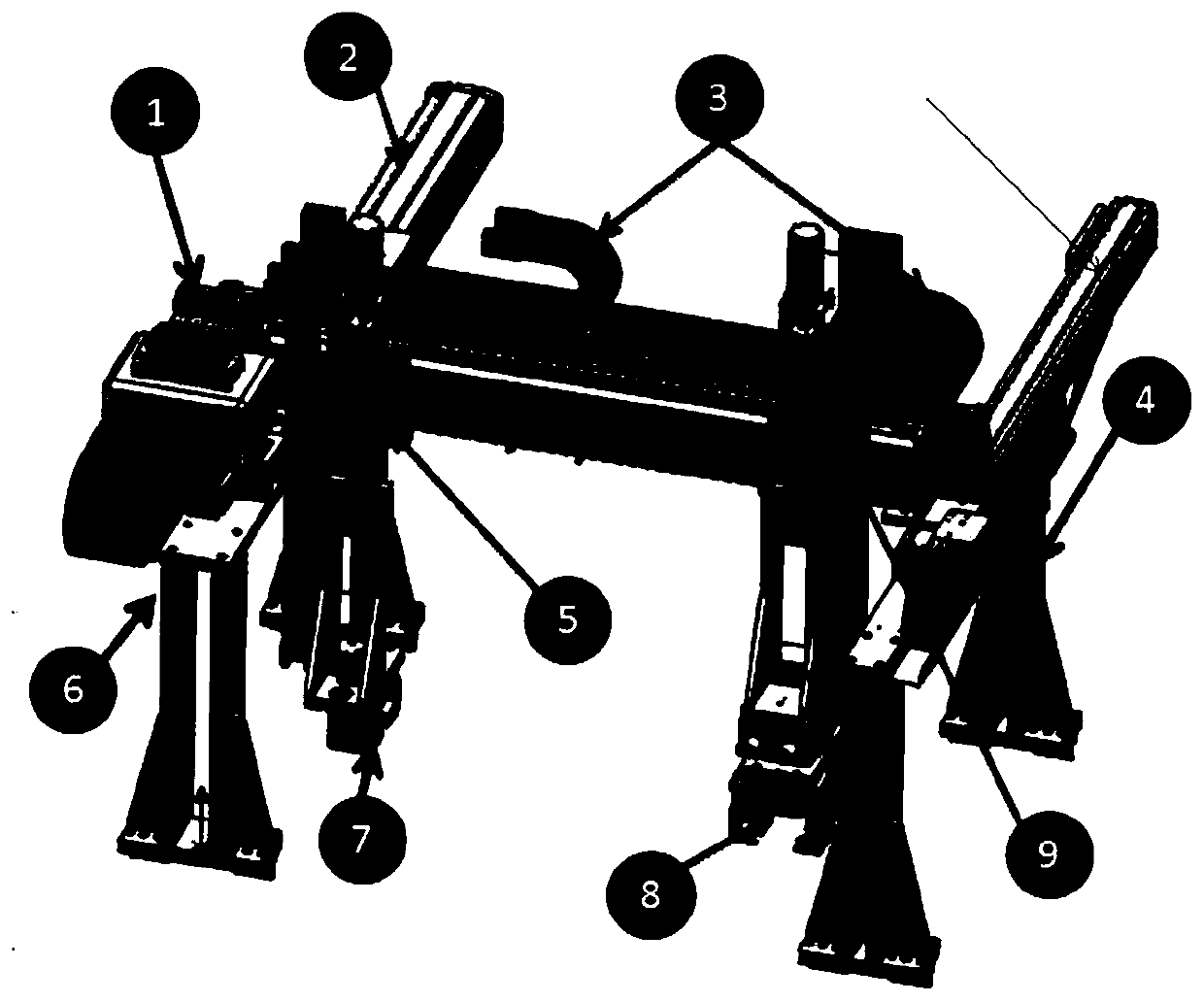

[0031] Grab mechanism 13, used to grab the inductance coil to be wound to the winding mechanism of the winding station, or take out the processed inductance coil from the winding mechanism of the winding station and place it on the tooling board to be transported to the next process.

[0032] The win...

Embodiment 2

[0051] According to an embodiment of the present invention, a method embodiment of a winding processing method for an induction coil is provided. It should be noted that the winding processing method for an induction coil is applied to any one of the above-mentioned winding processing systems for an induction coil , the steps shown in the flow diagrams of the figures may be implemented in a computer system, such as a set of computer-executable instructions, and, although shown in the flow diagrams, the steps may in some cases be executed in a logical order different from The sequence herein performs the steps shown or described in sequence.

[0052] Figure 5 It is a flow chart of the winding processing method of the inductance coil according to the embodiment of the present invention, such as Figure 5 As shown, the winding processing method of the inductance coil includes the following steps:

[0053] In step S502, it is determined that the inductor coil to be wound is tra...

Embodiment 3

[0062] According to another aspect of the embodiments of the present invention, a winding processing device for an induction coil is also provided. It should be noted that the winding processing device for an induction coil is applied to the induction coil of any one of the above-mentioned embodiment 2. winding method, Figure 7 It is a schematic diagram of a winding processing device for an inductance coil according to an embodiment of the present invention, such as Figure 7 As shown, the winding processing device of the inductor includes: a determination unit 71 , a control unit 73 and a winding unit 75 . The winding processing device for this inductor coil will be described in detail below.

[0063] The determination unit 71 is configured to determine that the inductance coil to be wound is transported to the winding station.

[0064] The control unit 73 is used to control the grabbing mechanism to take out the inductance coil to be wound from the tooling board and place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com