Method for measuring length of superconductive braided flat wire by utilizing accumulation of turn number

A number of turns, superconducting technology, applied in the field of superconducting braided flat wire length, can solve the problems of high cost, not suitable for large-scale production, easy to damage the braiding layer, etc., achieve process standardization, solve instability factors, and simple operation the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: The present invention uses the cumulative number of turns to measure the method for the length of superconducting braided flat wire

[0041] The invention provides a method for measuring the length of a superconducting braided flat wire by accumulating the number of turns, comprising the following steps:

[0042] (1) Measure the cylinder diameter D of the braided wire take-up wheel.

[0043] (2) Clean the close-packed rewinding equipment, put the reel 1 into the close-packed rewinding equipment take-up machine, prepare a superconducting flat wire with a braided layer, and fix the superconducting flat wire to the close-packed rewinding equipment Pay-off machine, pass the thread ends through each guide wheel, laser meter system and cable arrangement in turn, and finally receive it on the take-up wheel, set the rewinding tension to 20N, start densely arranging rewinding wires, and the rewinding speed is less than 50m / min, start the laser meter counter and t...

Embodiment 2

[0051] Embodiment 2: Accuracy measurement of the method of measuring the length of superconducting braided flat wire by accumulative number of turns in the present invention

[0052] Step 1: Take 4 selected wire wheels, clean the surface in contact with the wire, wipe it with clean water, dehydrate with absolute ethanol, and blow dry.

[0053] Step 2: Use a long claw vernier caliper to measure the cylinder diameter of each reel to ensure that the cylinder diameter is within D 名义 Within the range of ±1mm, they are named as spool 2, spool 3, spool 4, and spool 5. Please refer to the appendix figure 1 .

[0054] Step 3: Select 4 wires with the same nominal size as NbTi 1, and name them NbTi 2, NbTi 3, NbTi4, and NbTi 5 respectively.

[0055] Step 4: Select the corresponding reel and wire (such as reel 2 and NbTi 2), and prepare for rewinding, that is, step 3 (step 1 to step 4).

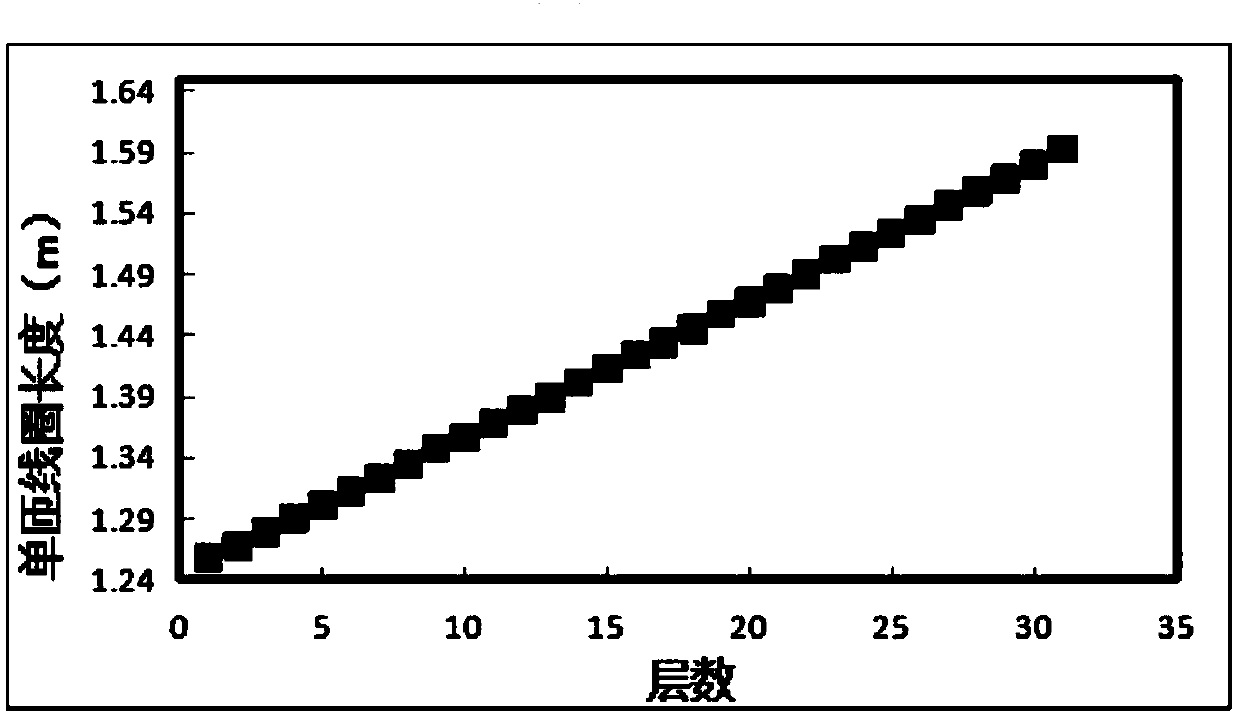

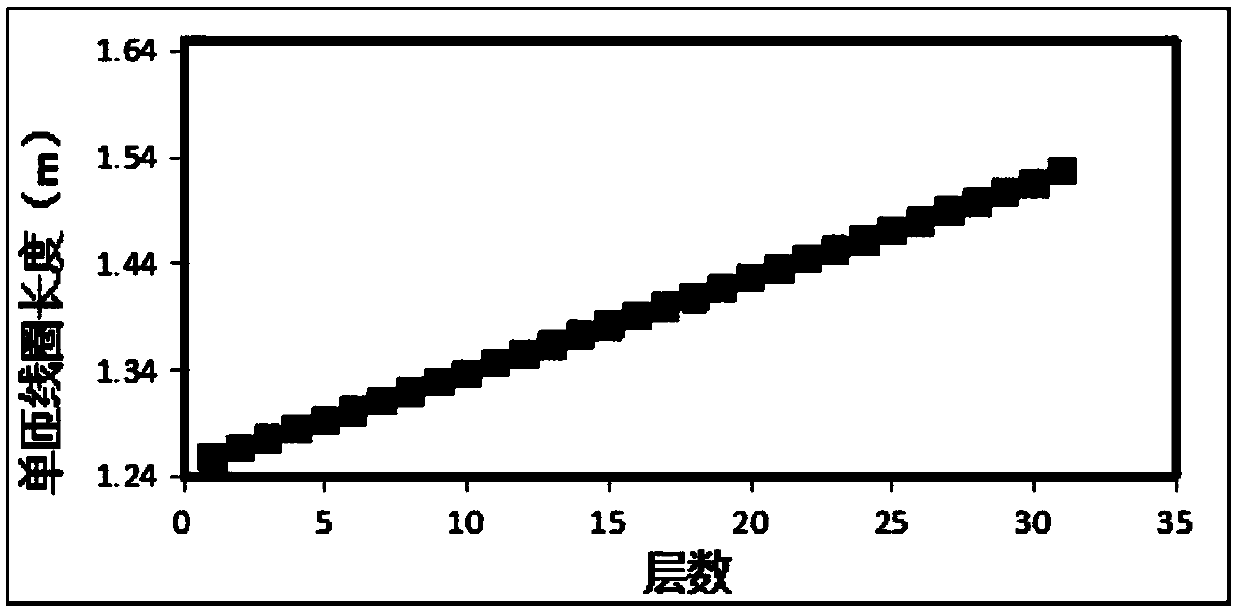

[0056] Step 5: Increase the number of turns counter on the rewinding equipment, see the attached ...

Embodiment 3

[0060] Embodiment three: the volume measuring device of the present invention

[0061] In the present invention, the braided wire take-up reel is put into the volume measuring device to measure the volume, and the braided wire take-up reel is classified according to different specifications through the detection liquid volume discharged after the braided wire take-up reel is put in. The volume measurement device includes a detection Tank 1, detection liquid tank 2 and pipeline 4, the bottom of the detection tank 1 and detection liquid tank 2 are connected through the pipeline 4, a telescopic rod 3 is arranged under the middle part of the pipeline 4, a valve 5 is arranged on the pipeline 4, and the detection tank 1 There is a gap on the side, and a sealing plate 7 is provided at the gap, and the sealing plate 7 protrudes through the bottom of the detection tank 1, and a measuring tube 6 is provided on the side of the testing tank 1 opposite to the gap, and the measuring tube 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com