Microwave drying device capable of integrating preheating and strong wind heat dissipation

A technology of microwave drying and strong wind, which is applied in the direction of drying, drying machine, heating to dry solid materials, etc., can solve the problems of poor heat dissipation, inability to eliminate, and poor heating effect, so as to improve energy utilization rate, even heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

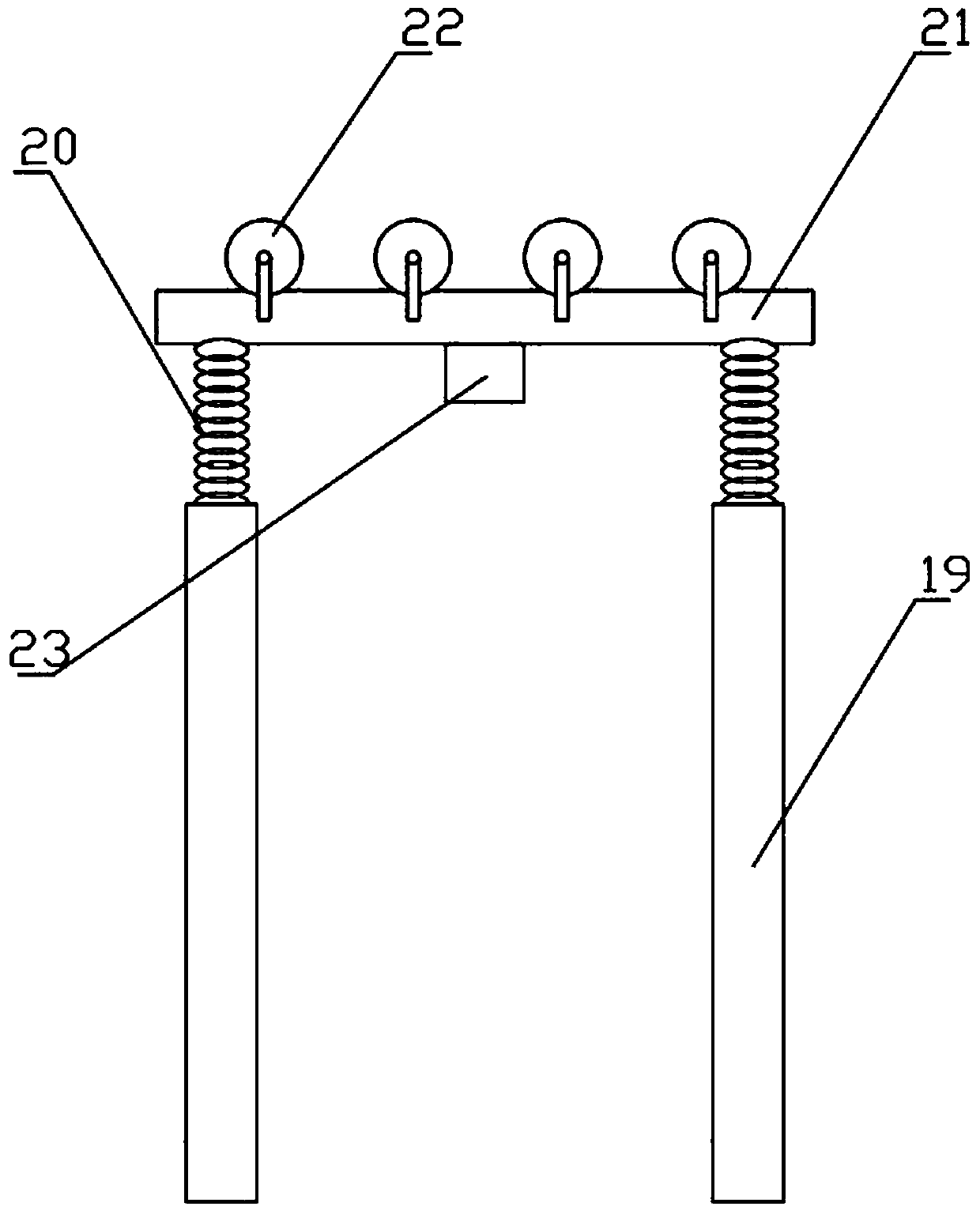

[0033] Such as Figure 1-Figure 6 as shown,

[0034] A microwave drying device integrating preheating and strong wind heat dissipation, including:

[0035] A belt conveyor 1 for transporting materials. The belt conveyor 1 includes a roller, an idler roller and a conveyor belt. The conveyor belt is a Teflon grid conveyor belt. The roller includes a driving roller 101 and a passive roller 102. The driving roller 101 and The driven roller 102 is wound with a conveyor belt 103, the driving roller 101 is connected with the motor and the reducer, the driving roller 101 and the driven roller 102 are arranged at both ends of the belt conveyor 1, and the idler roller 104 is sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com