Microchannel heat exchanger

A micro-channel heat exchanger and header technology, which is applied in the heat exchanger shell, heat exchange equipment, evaporator/condenser, etc., can solve the problem of reducing the diameter of the header, reducing the performance of the heat exchanger, and preventing liquid separation. Equalize the problem to achieve the effect of increasing the refrigerant flow rate, reducing the charging amount, and improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

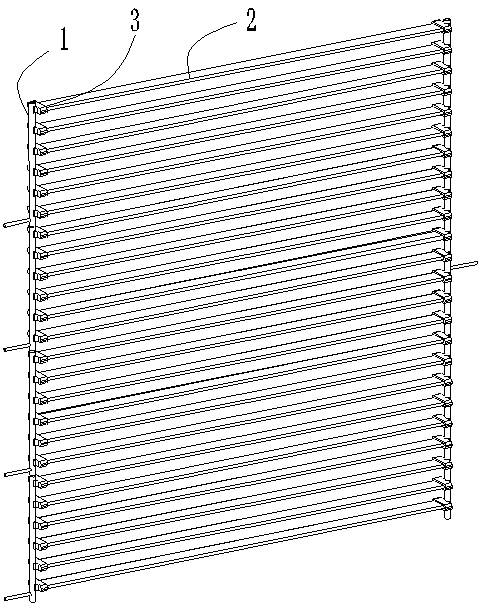

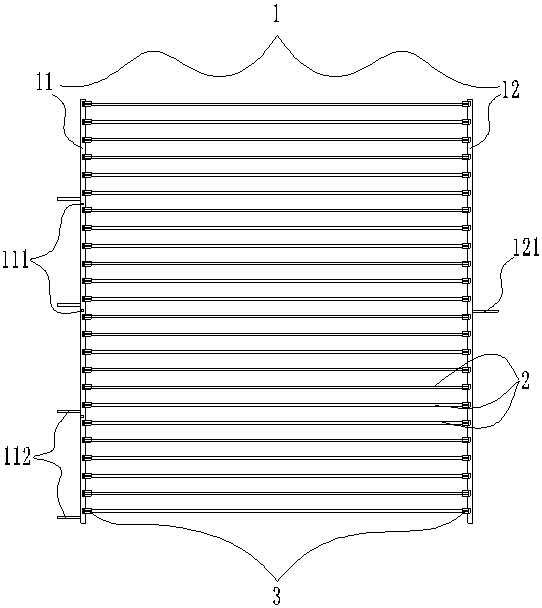

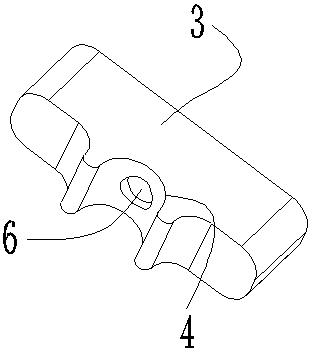

[0031] Such as figure 1 As shown, the embodiment of the present invention provides a microchannel heat exchanger, including two headers 1, a plurality of flat tubes 2, a plurality of flat tubes 2 vertically communicated between the two headers 1, the flat tubes 2 The two ends are connected with a plurality of connectors 3 for connecting two headers 1, the diameter of the header 1 connected at one end of the connector 3 is smaller than the width of the flat tube 2 connected at the other end of the connector 3, further, One end of the connector 3 is provided with a header slot 4 for fixing the header 1, and the other end is provided with a flat tube slot 5 for fixing the flat tube 2. There is a space between the header slot 4 and the flat tube slot 5. In connection with the connection hole 6 connecting the header slot 4 and the flat tube slot 5, through the connection hole 6, the communication between the header and the flat tube can be ensured. The connector 3, the connector 3...

Embodiment 2

[0038] The difference between this embodiment and the first embodiment is that one end of the connector 3 is provided with a convex tube 7 for fixing the liquid collecting pipe 11 and the gas collecting pipe 12, and the other end is provided with a flat tube limiting groove for fixing the flat tube 2 8. There is a connecting channel 9 for connecting the convex tube 7 and the flat tube limiting groove 8 between the convex tube 7 and the flat tube limiting groove 8. Further, one end of the connector 3 communicates with the header 1 through the convex tube 7 , the other end communicates with the flat tube 2 through the flat tube limiting groove 8, wherein the liquid collecting pipe 11 and the gas collecting pipe 12 are assembled with the convex tube 7 of the connector 3, and the flat tube 2 is connected with the flat tube limiting groove 8 of the connector 1 Assembling, the convex pipe 7 is inserted into the header hole 13, the assembly is simple, and the processing procedure is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com