In-pipeline working body transporting and positioning device, transporting method and positioning method

A technology for positioning devices and working bodies, which is applied in the direction of special pipes, pipe components, pipes/pipe joints/pipe fittings, etc., and can solve problems that are difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

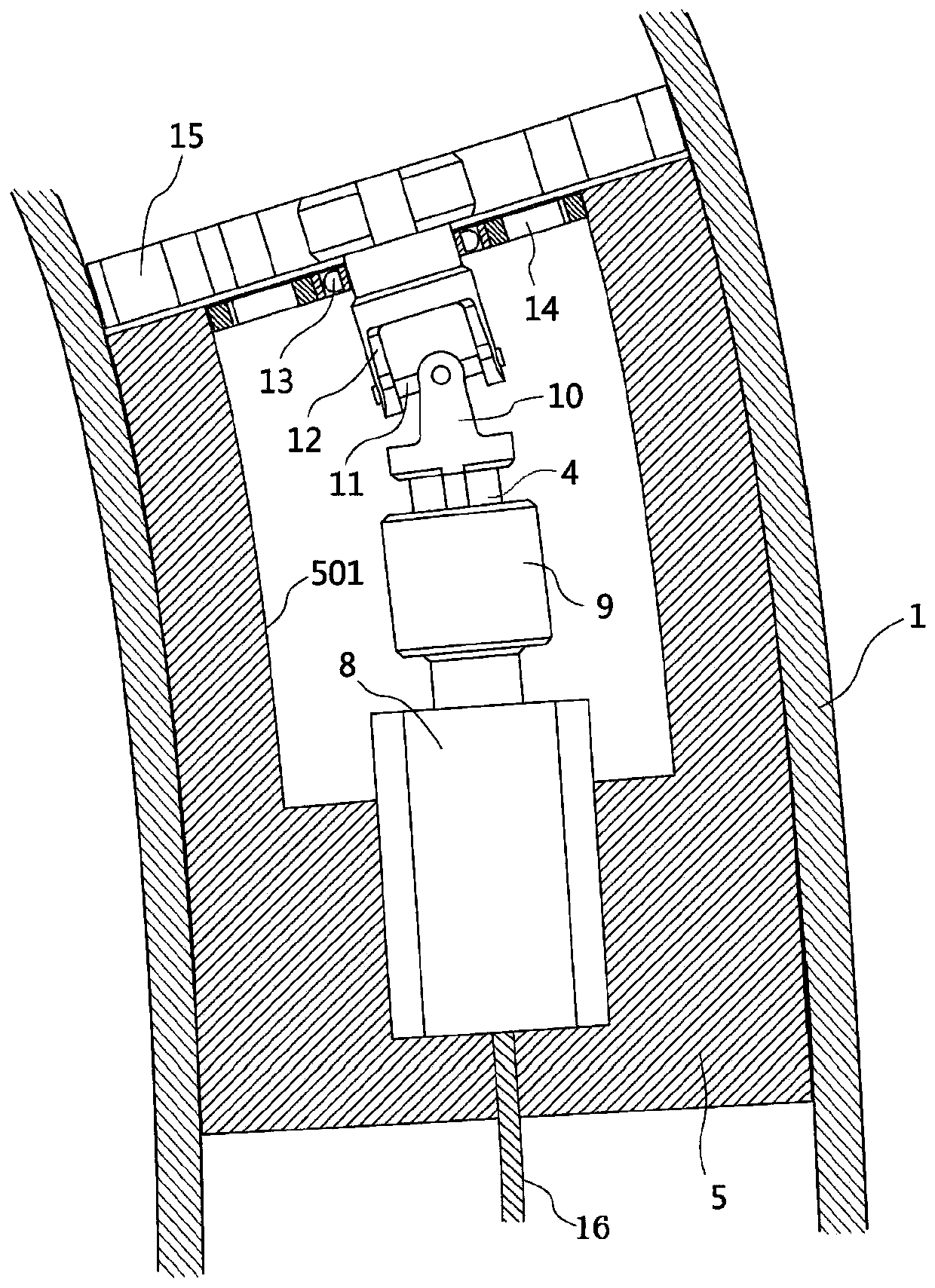

[0057] The working body 6 is a camera; when the inner wall of the pipeline 1 needs to be overhauled, the working body 6 is replaced with a camera with a light, and the camera can take pictures and videos of the inner wall of the pipeline 1 to know the situation of the inner wall of the pipeline 1.

[0058] The working body 6 is a drilling device; when drilling operations need to be performed on the inner wall of the pipeline 1, the working body 6 can be replaced with a common drilling device with a drill bit.

[0059] The working body 6 is a cutting and finishing device for the inner wall of the pipeline; the cutting and finishing device for the inner wall of the pipeline can uniformly cut and finish the inner wall of the curved pipeline 1 .

[0060] It should be noted that the working body 6 is not limited to the above-mentioned several embodiments, and can also be any device for performing other operations on the pipeline 1 .

[0061] It should be noted that if the drilling ...

Embodiment 3

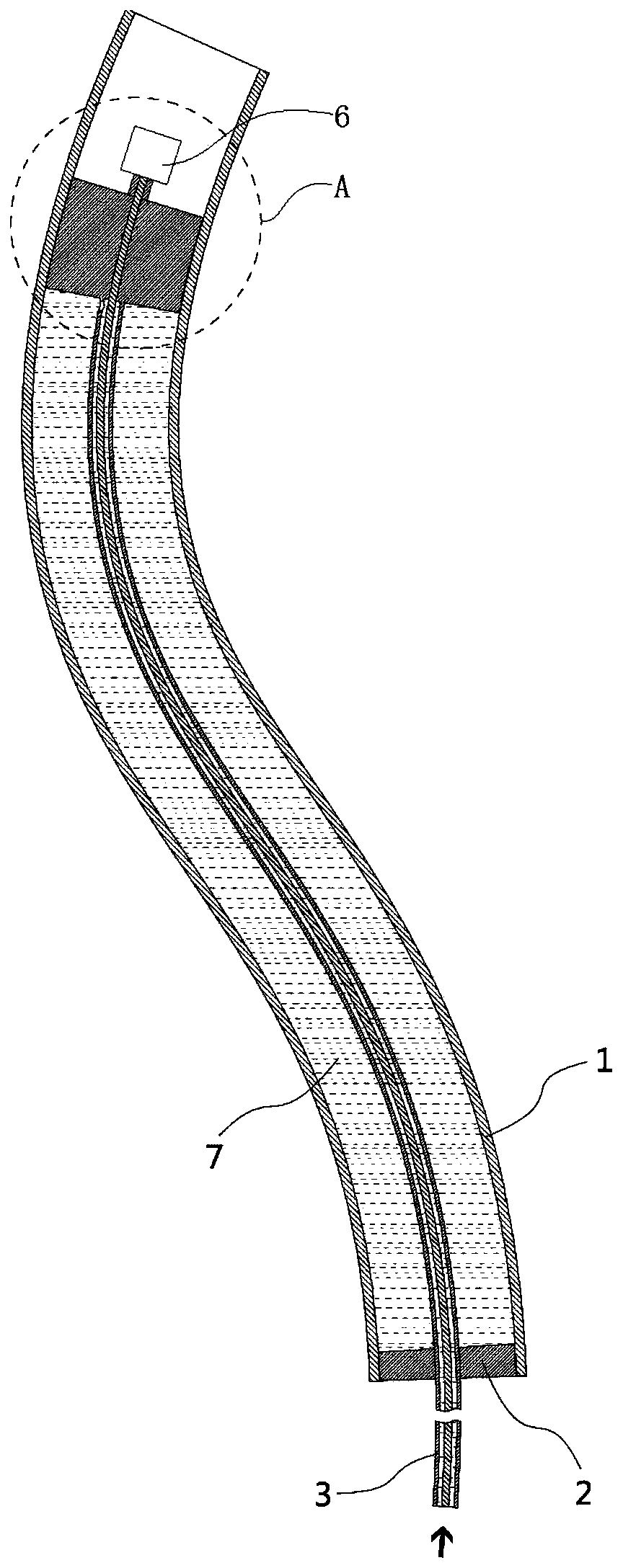

[0081] A method for transporting a working body in a pipeline, using the positioning device for transporting a working body in a pipeline according to Embodiment 1, comprising the following specific steps:

[0082] Step 1: Measure the inner diameter of the pipe; first use an inner diameter measuring device such as a vernier caliper to measure the inner diameter of the pipe, and skip this step if the inner diameter is known.

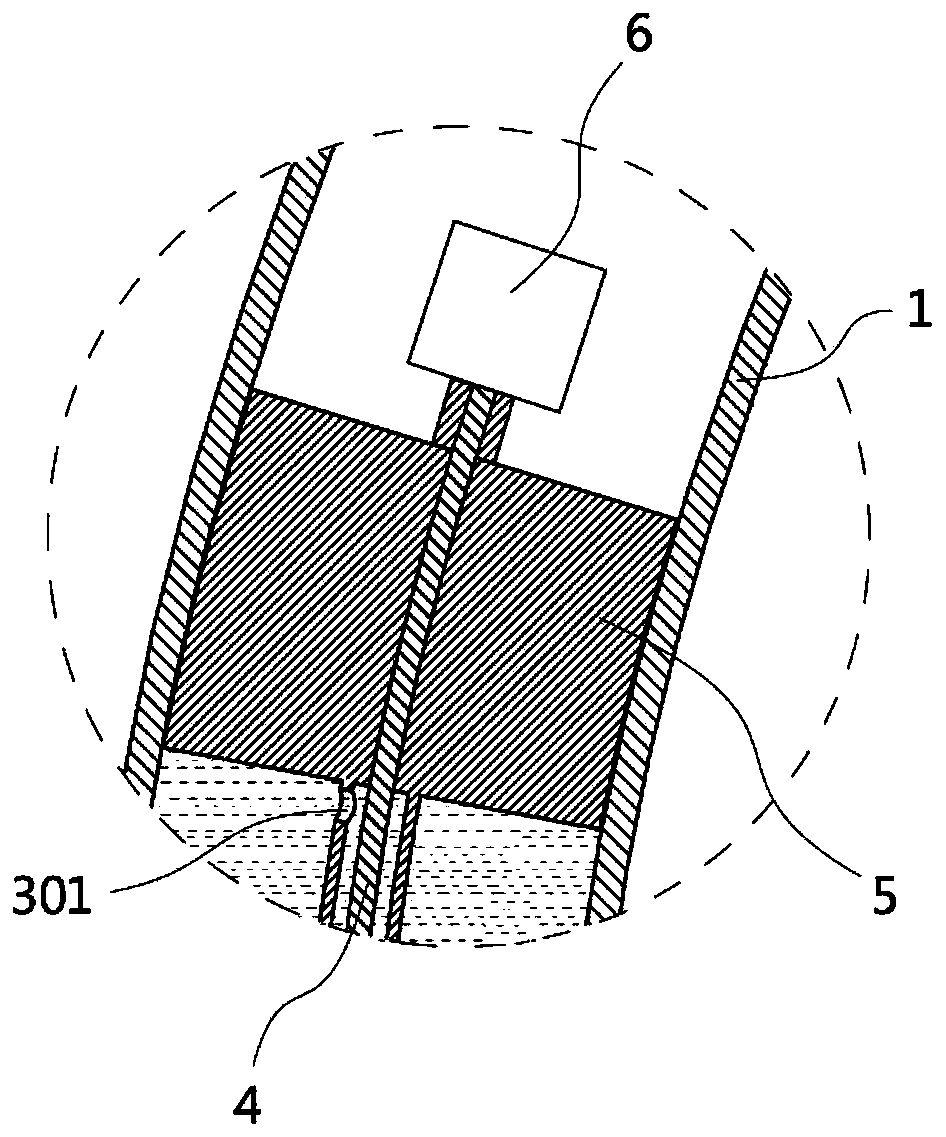

[0083] Step 2: Initialize the working state; select the corresponding first rubber plug 2 and second rubber plug 5 according to the inner diameter of the pipe, and then empty the inside of the flexible pipe 3. If there is hydraulic oil remaining in the flexible pipe 3, use a hydraulic pump to evacuate it ; or blowing high-speed airflow into the flexible pipe 3 to discharge the hydraulic oil in the flexible pipe 3, and then connect the working body in the pipeline 1 to transport the positioning device. Then put the tail of the second rubber plug 5 close to...

Embodiment 4

[0087] A method for positioning a working body in a pipeline, based on the positioning of the working body in the pipeline during transportation,

[0088] Step A: Measure the distance l traveled by the flexible pipe 3 1 ; With the initial state in step 2 as the starting point of the flexible pipe 3, straighten the flexible pipe 3 outside the pipeline 1, and look for a reference point on the flexible pipe 3, such as the position where the flowmeter is installed, when the flexible pipe 3 is When the second rubber stopper 5 advances to the inside of the pipe 1, measure the distance advanced by the reference point to obtain the distance l traveled by the flexible pipe 3 1 .

[0089] Step B: Calculate the volume of hydraulic oil in pipeline 1. The flowmeter can measure the total amount of hydraulic oil flowing through. The distance between the installation position of the flowmeter and the joint between the flexible pipe 3 and the second rubber plug 5 is known when the flowmeter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com