Numerical control machine tool automatic wiring device

A technology of automatic wiring and CNC machine tools, which is applied in the direction of positioning devices, feeding devices, metal processing machinery parts, etc., and can solve problems such as weakening of the sealing effect, wiring, and difficult inner walls of pipe fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings.

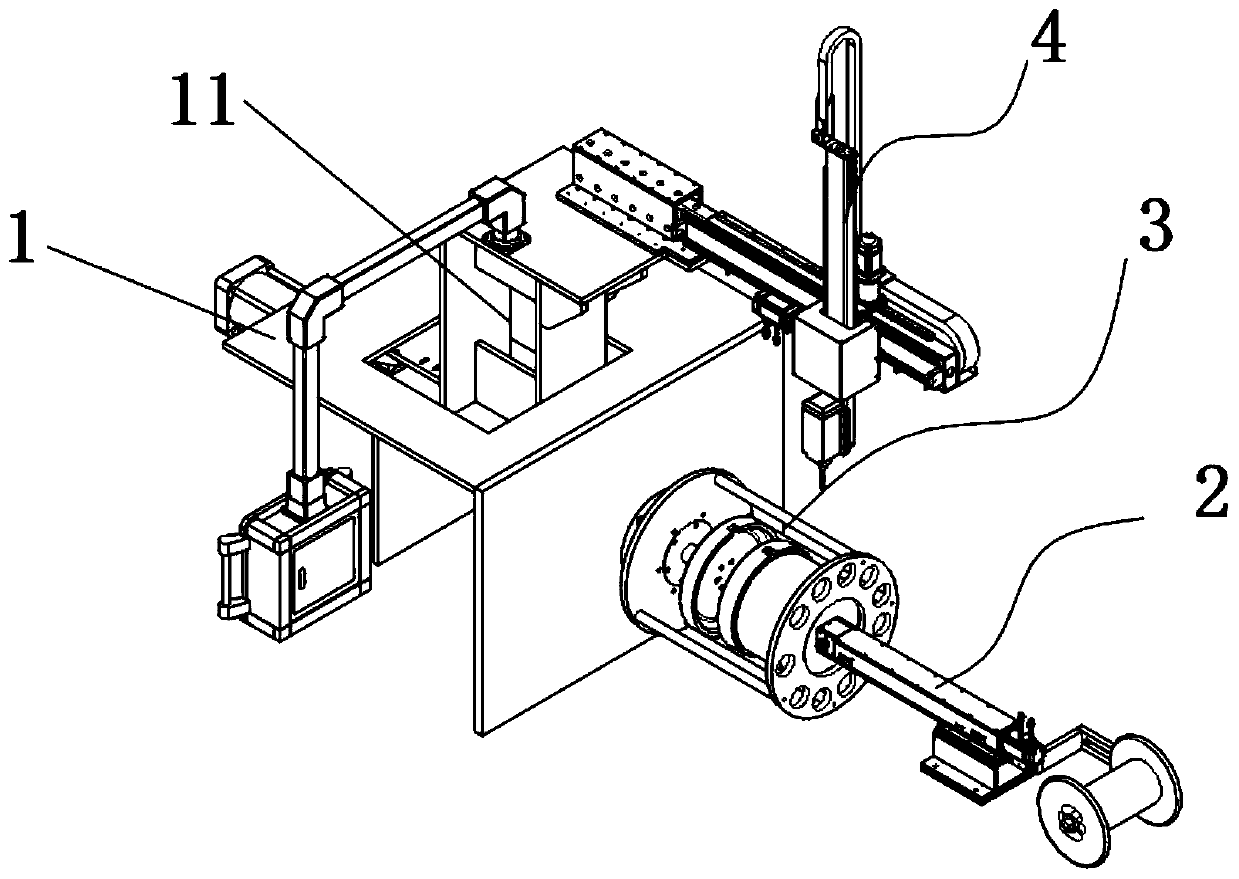

[0022] like figure 1 As shown, a CNC machine tool automatic wiring device is provided, including a CNC machine body 1, a tool rest module 2 arranged on the body 1, a clamp module 3 connected to the tool rest module 2, and gears are arranged in the body 1 The box 11 and the gear box 11 are externally connected with a drilling module 4 .

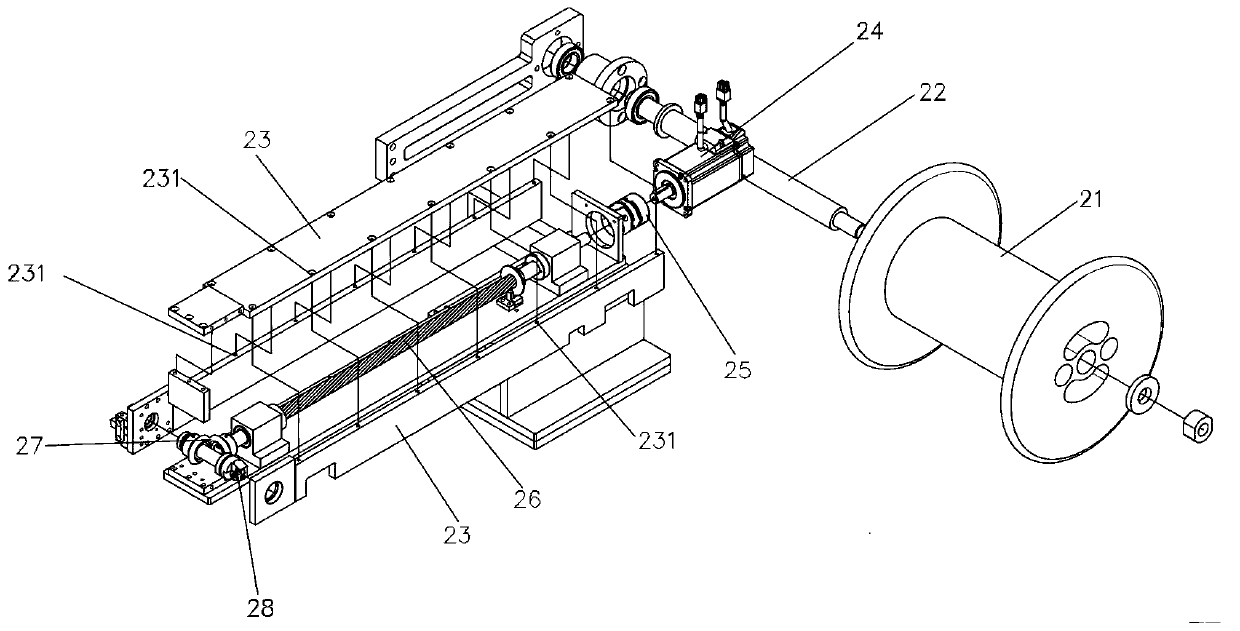

[0023] like figure 2 As shown, wherein: the tool post module 2 includes a wire wheel 21, the wire wheel 21 is I-shaped, the wire wheel shaft 22, and the wire wheel 21 is arranged on the wire wheel shaft 22; the connecting bracket 23 is set on the connecting bracket 23 There are a plurality of threading holes 231; the servo motor 24, the shaft coupling 25 connected with the servo motor 24, the gear shaft 26 connected with the shaft coupling 25, and a pair of bevel gears 27 are arranged at the output end of the gear shaft 26, the one A cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com