Earth tunnel supporting structure passing through existing railway and construction method thereof

A technology for existing railways and supporting structures, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of slow construction progress, low construction efficiency, and large jacking thrust loss, so as to facilitate prefabrication and installation, and reduce construction costs. Cost, the effect of increasing cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

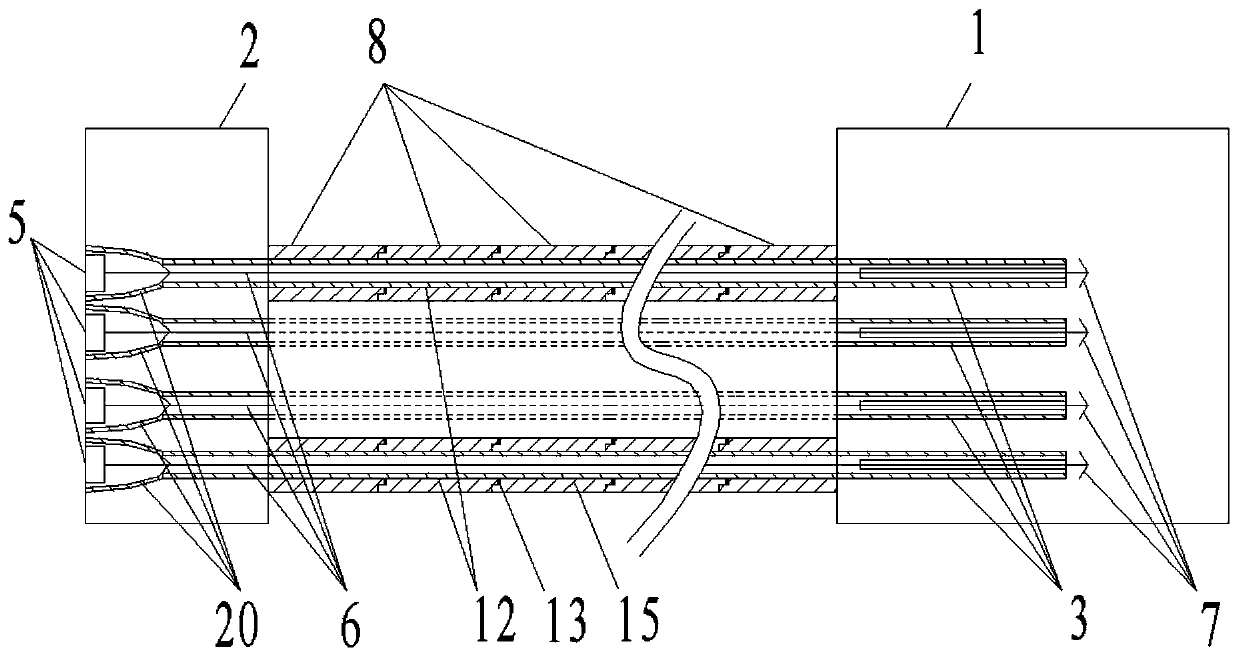

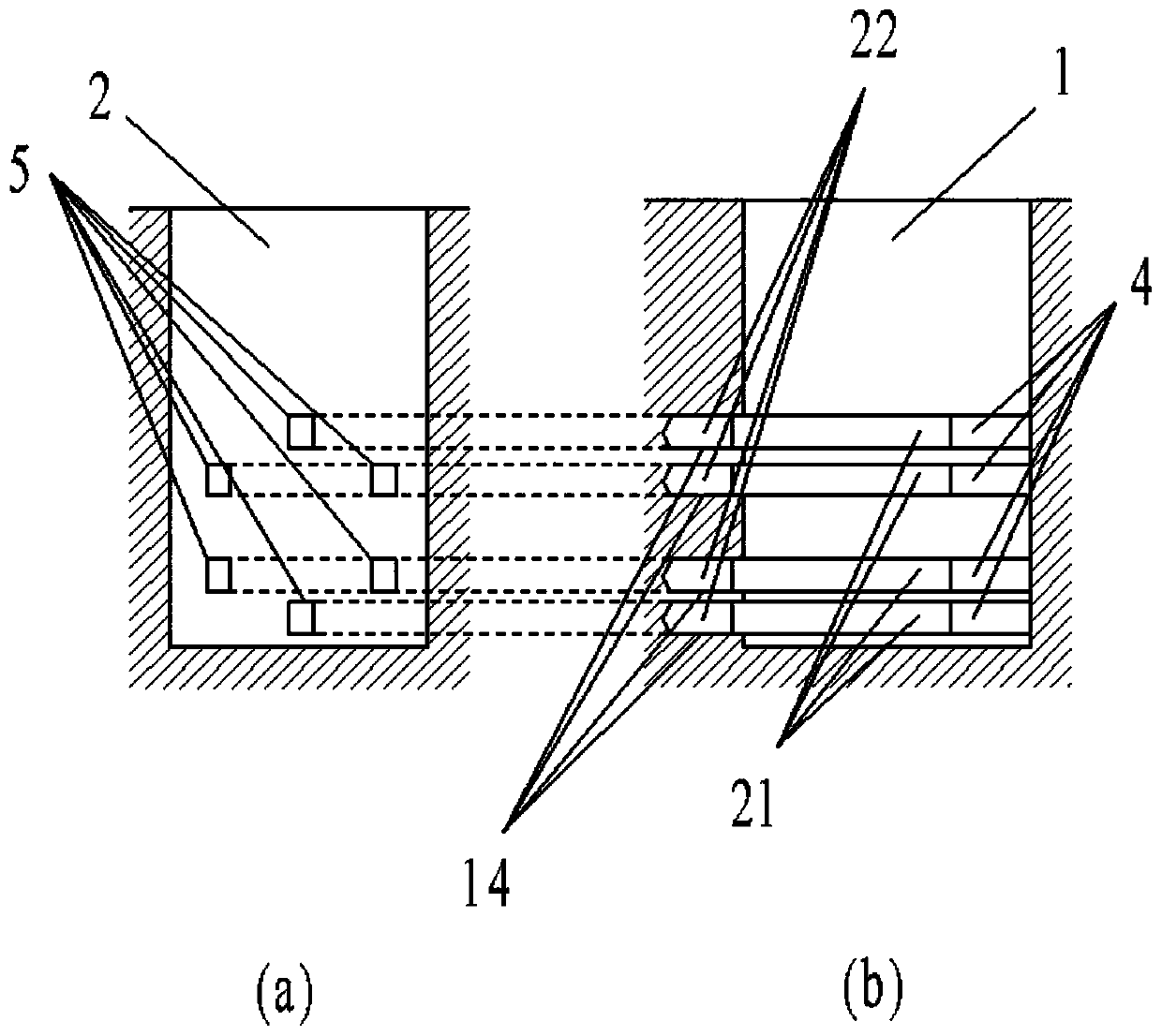

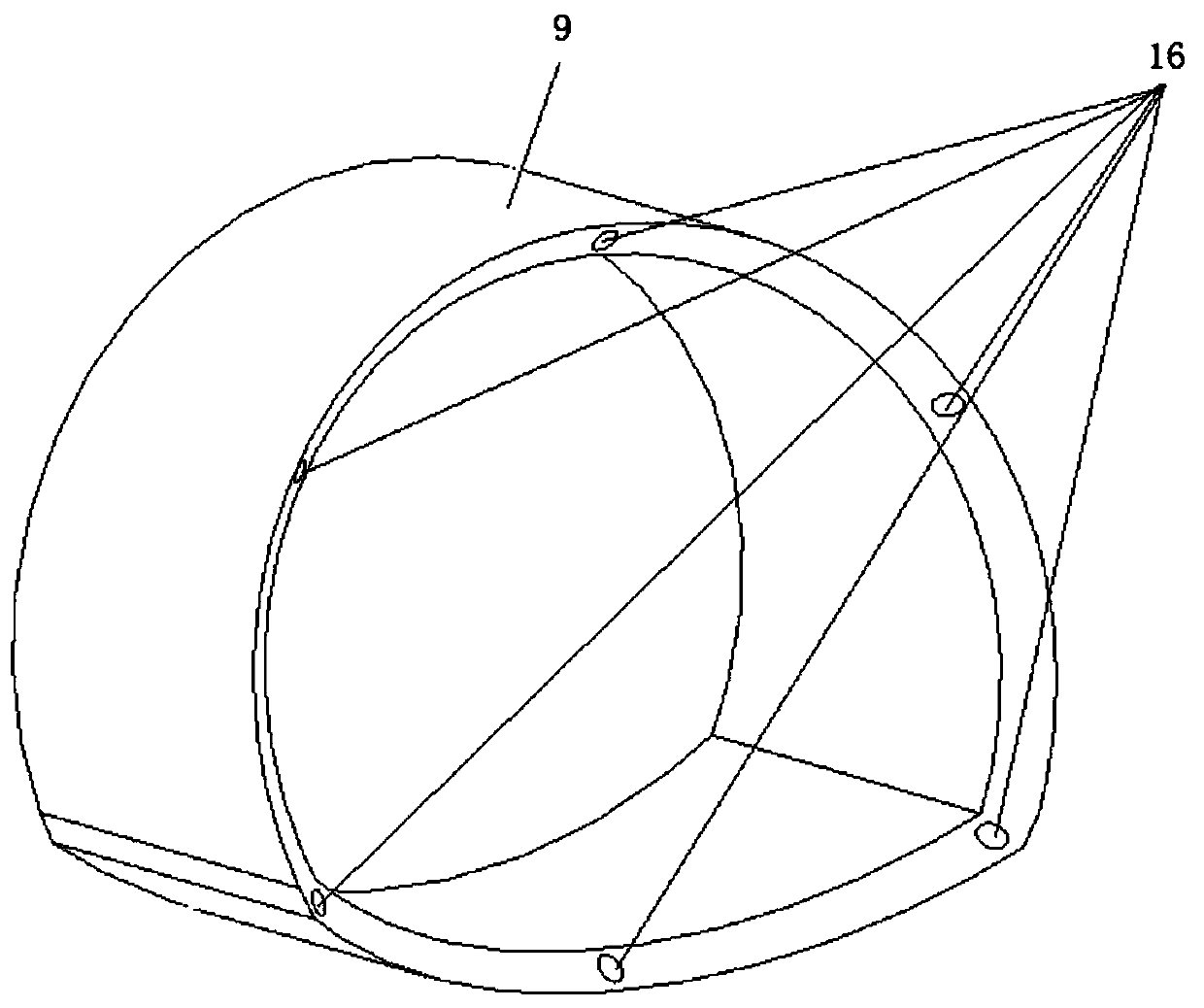

[0063] see figure 1 , a support structure for an earth tunnel passing through an existing railway, comprising a starting shaft 1 and a receiving shaft 2, a supporting pipeline 15 is arranged between the starting shaft 1 and the receiving shaft 2, and the supporting pipeline 15 A positioning conduit 3 passes through the pipe section hole 12 reserved above; one end of the positioning conduit 3 is located in the starting well 1 , and the other end of the positioning conduit 3 is located in the receiving well 2 .

[0064] see figure 1 , a kind of soil tunnel support structure construction method that crosses existing railway, comprises the following steps:

[0065] Step 1: Preparatory work for construction, including:

[0066] 1.1. Select areas on both sides of the existing railway, and construct the originating shaft 1 and the receiving shaft 2;

[0067] 1.2. Set up several winches 5 on the well wall of the receiving shaft 2 away from the originating shaft 1, and set the drill...

Embodiment 2

[0108] see figure 1 , a support structure for an earth tunnel passing through an existing railway, comprising a starting shaft 1 and a receiving shaft 2, a supporting pipeline 15 is arranged between the starting shaft 1 and the receiving shaft 2, and the supporting pipeline 15 A positioning conduit 3 passes through the pipe section hole 12 reserved above; one end of the positioning conduit 3 is located in the starting well 1 , and the other end of the positioning conduit 3 is located in the receiving well 2 .

[0109] see figure 1 , a kind of soil tunnel support structure construction method that crosses existing railway, comprises the following steps:

[0110] Step 1: Preparatory work for construction, including:

[0111] 1.1. Select areas on both sides of the existing railway, and construct the originating shaft 1 and the receiving shaft 2;

[0112] 1.2. Set up several winches 5 on the well wall of the receiving shaft 2 away from the originating shaft 1, and set the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com