Special tool fixture for electronic product production

A technology for electronic products and fixtures, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of single clamping function, increase the labor load of operators, and unsatisfactory clamping effect, so as to ensure efficiency and reduce labor load. , The effect of easy assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

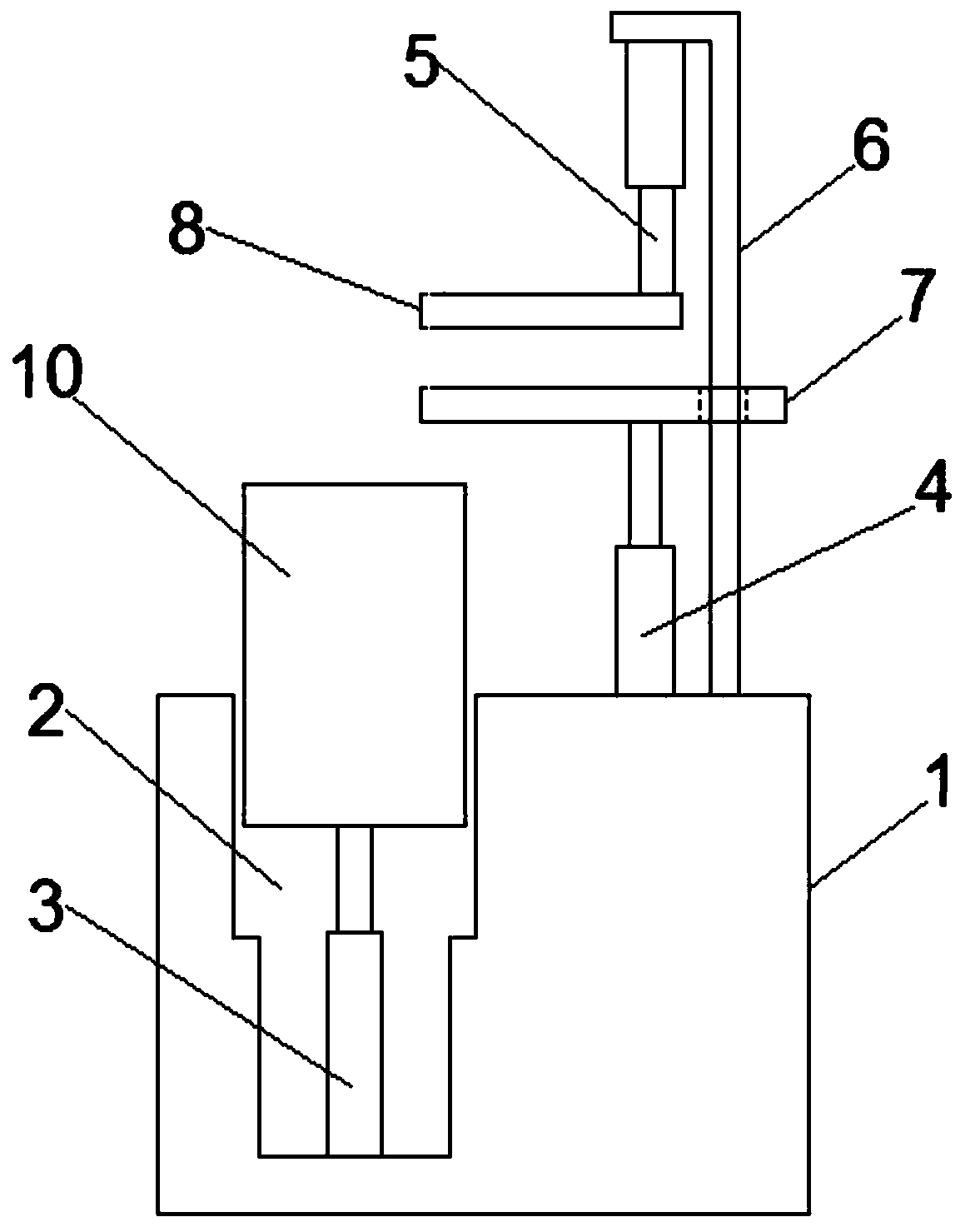

[0018] Such as figure 1 As shown, a special tooling fixture for the production of electronic products includes a support base 1, a first linear electric push rod 3, a second linear electric push rod 4, a third linear electric push rod 5, a lower splint 7 and a lower splint 7;

[0019] The left side of the upper part of the support base 1 is provided with a receiving groove 2; the right side of the upper part of the support base 1 is fixedly connected with a guide rod 6 at a position close to the right end;

[0020] The first linear electric push rod 3 is installed vertically in the middle of the receiving groove 2, its push rod end is located at the upper part, and the end is fixedly connected with the bottom center of the workbench 9 which is slidably arranged in the receiving groove 2 , for pushing the workbench 9 to move longitudinally in the receiving groove 2;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com