Three-dimensional automatic design method of gear

A design method and gear technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of complex involute gear drawing, low precision, and short gear life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

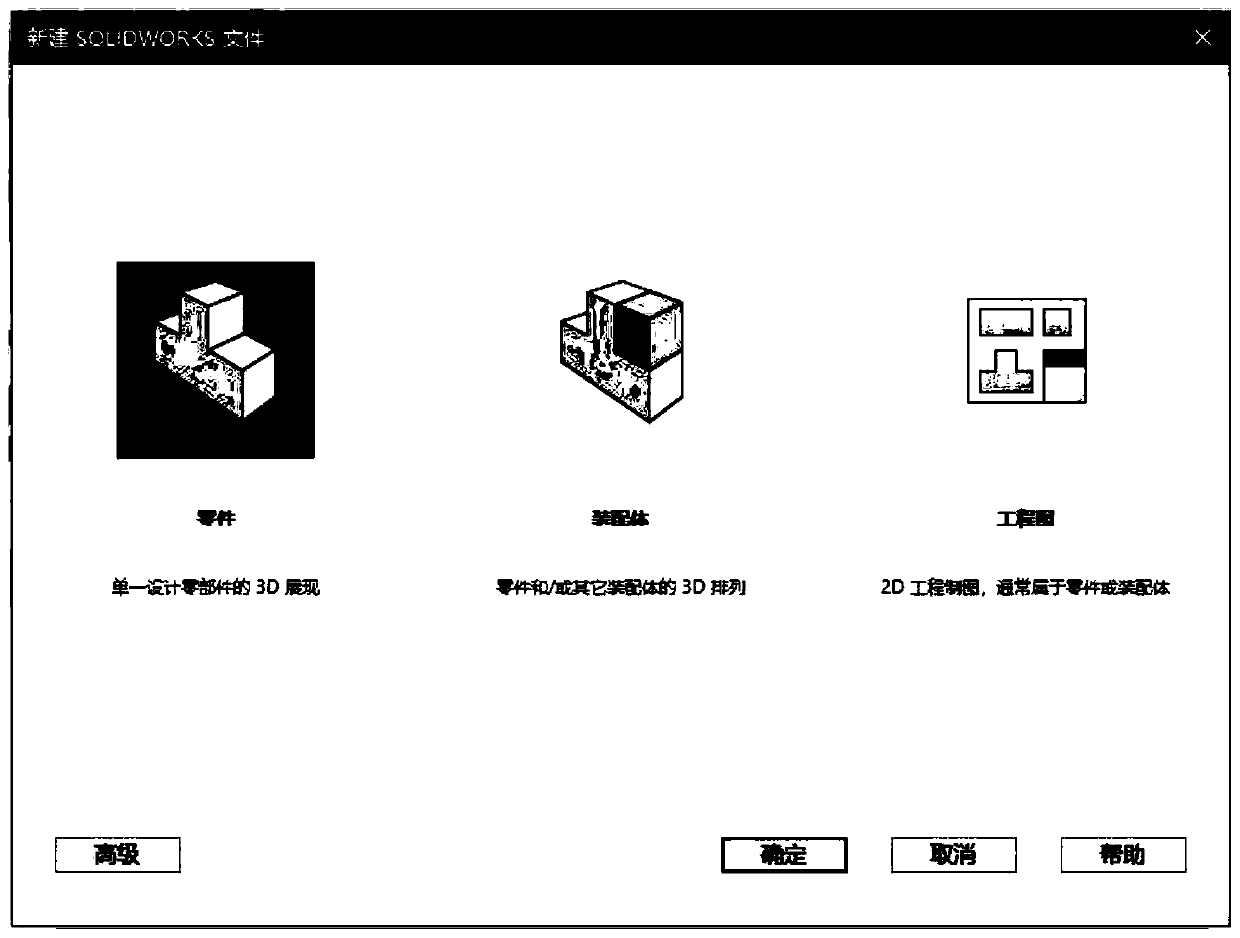

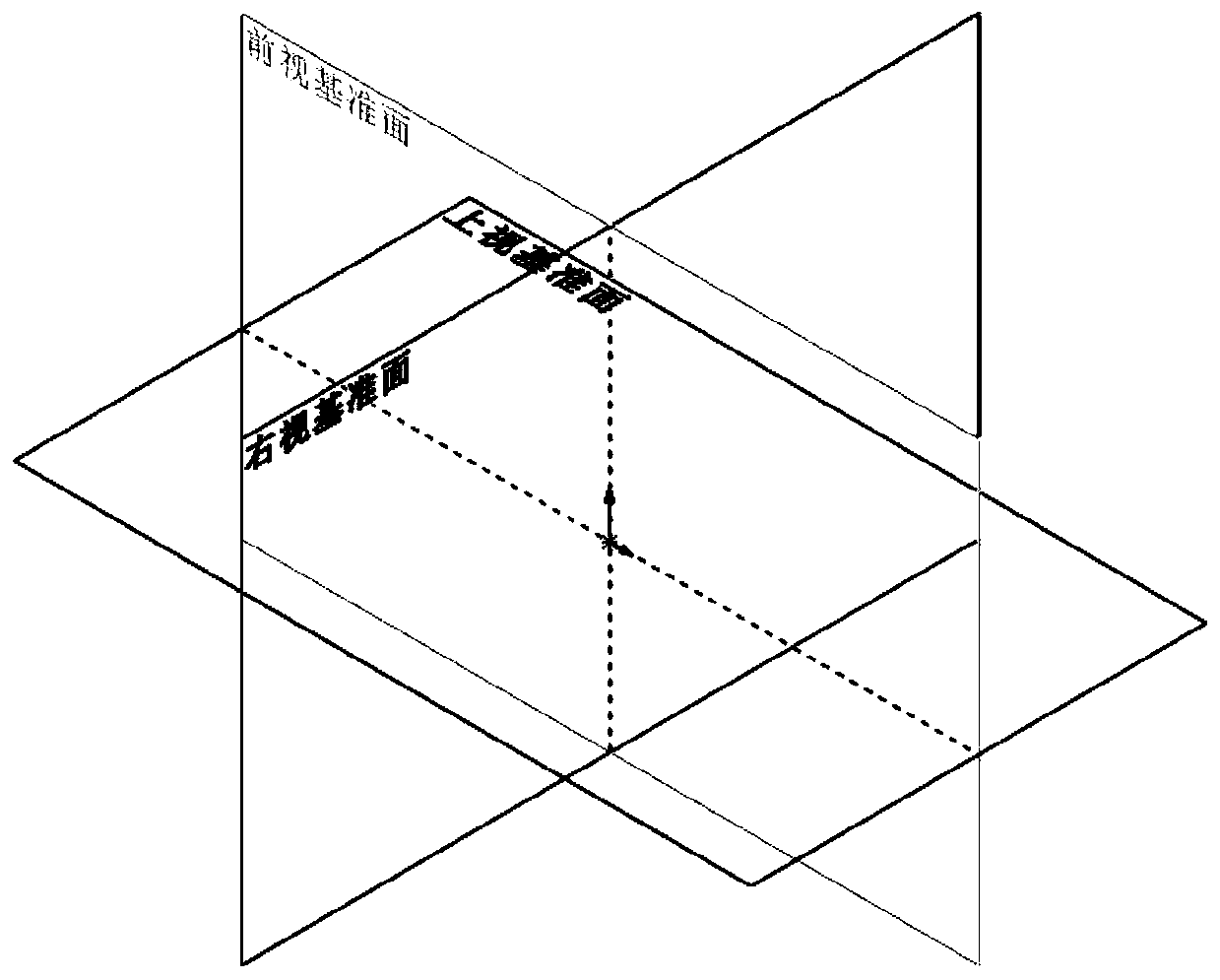

[0113] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0114] Using solidworks for parametric modeling of gears has the following meanings:

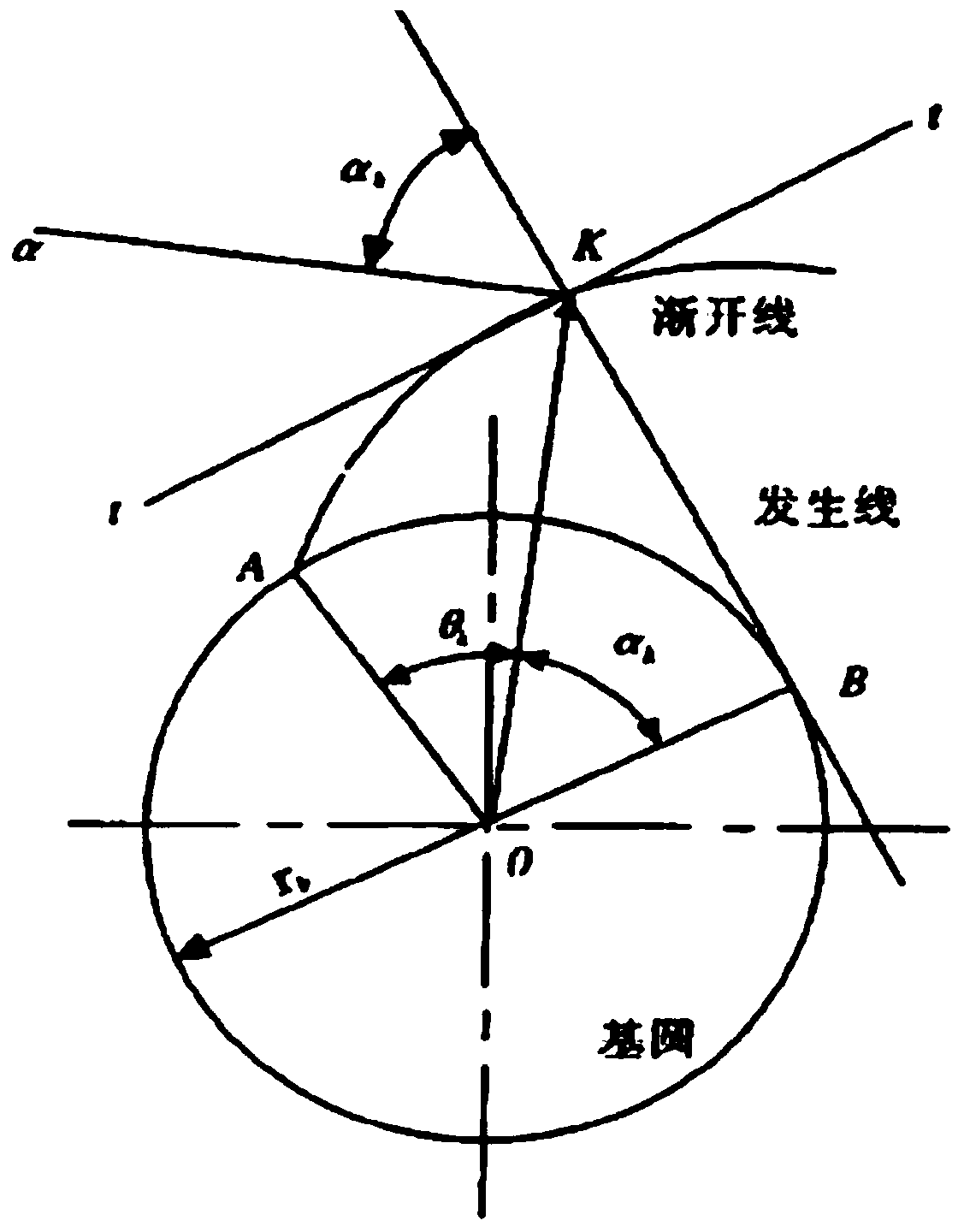

[0115] (1) There is an equation-driven curve function in the advanced version of Solidworks. Developers only need to input the involute equation of the gear into the corresponding dialog box to draw the corresponding involute, and can improve Accuracy of involute gears;

[0116] (2) If you want to draw different gear profiles, you only need to modify the parameters of the equation in the dialog box, and Solidworks can draw the gears that meet the requirements, which is convenient and quick, and saves time;

[0117] (3) It brings great convenience to gears in terms of mechanical design, manufacturing and CAE.

[0118] The present invention provides a three-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com