Variable-diameter drill bit device and hole digging device

A drill bit and equipment technology, which is applied to drilling equipment, drill bits, support devices, etc., and can solve the problems of increased drilling resistance, inconvenient use, and high labor intensity of the drill bit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

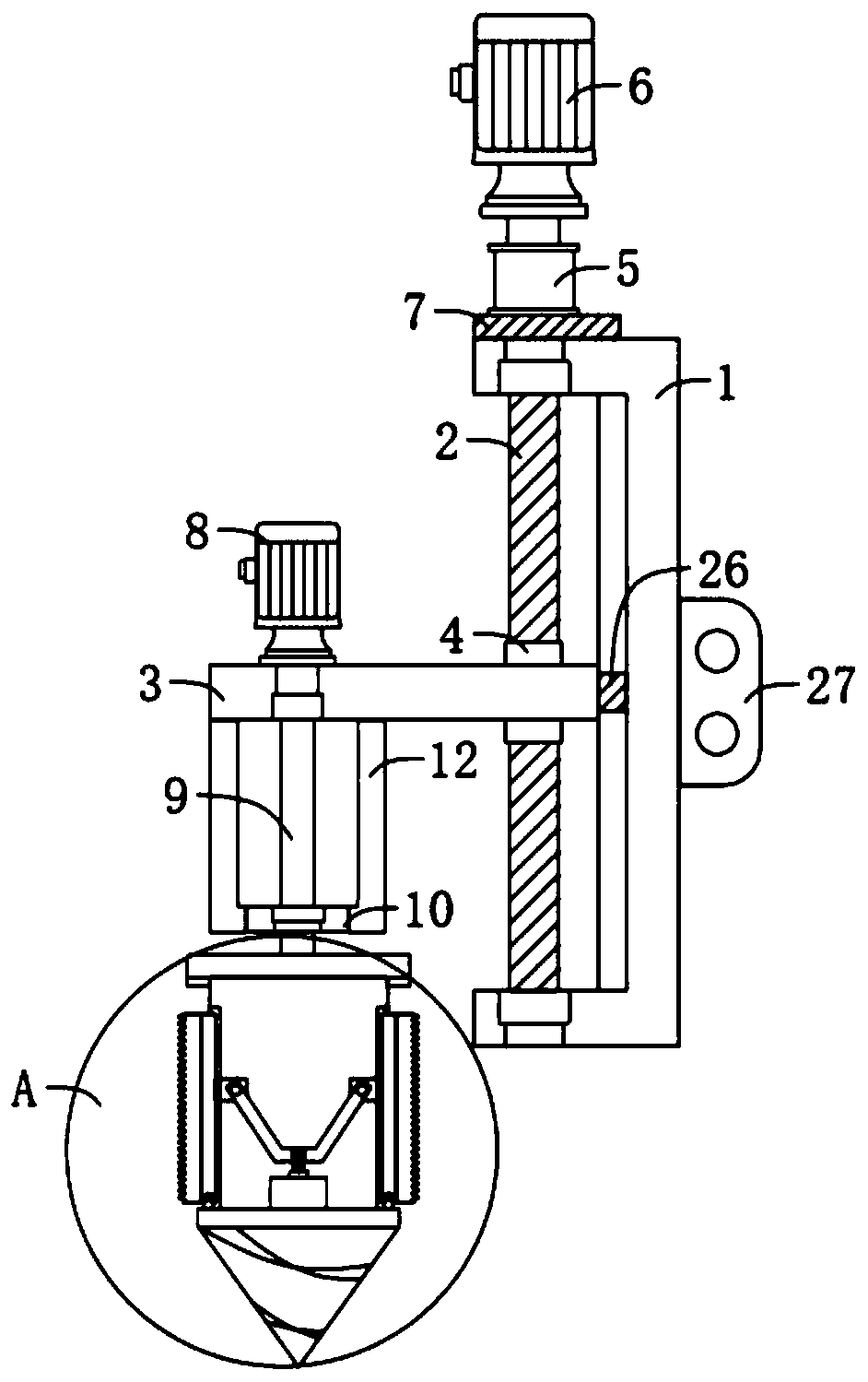

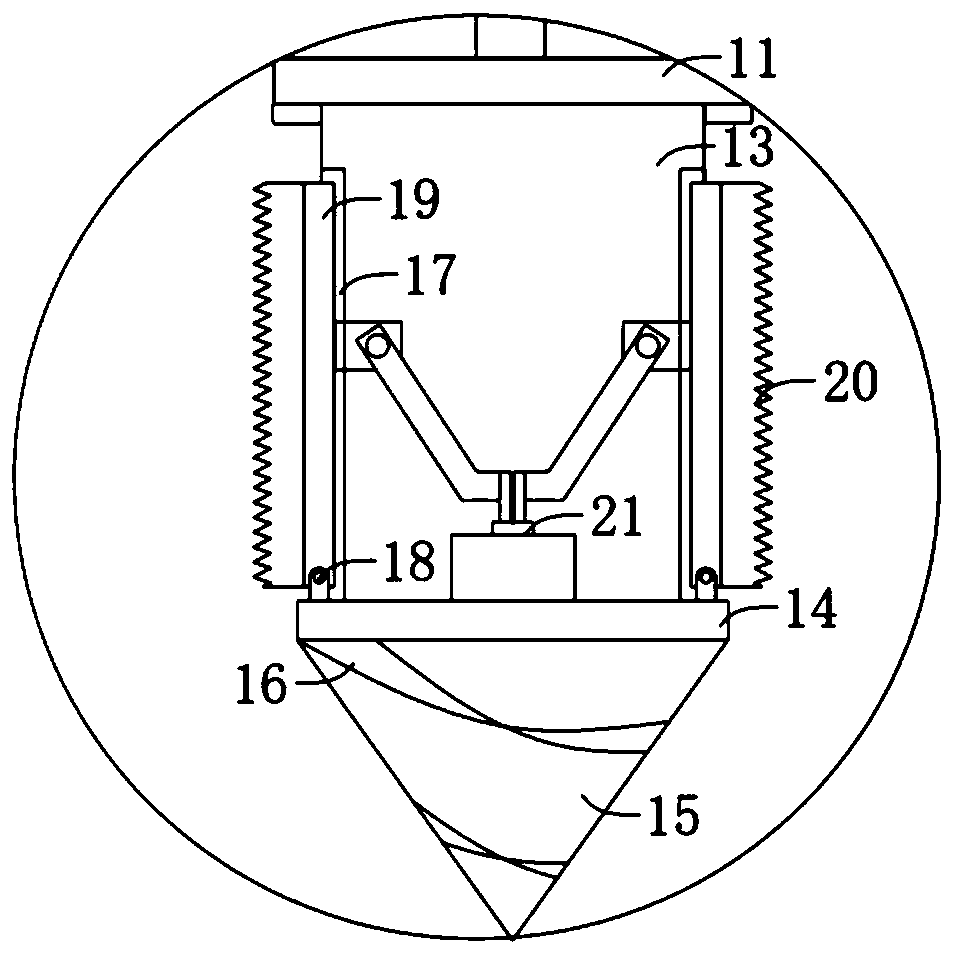

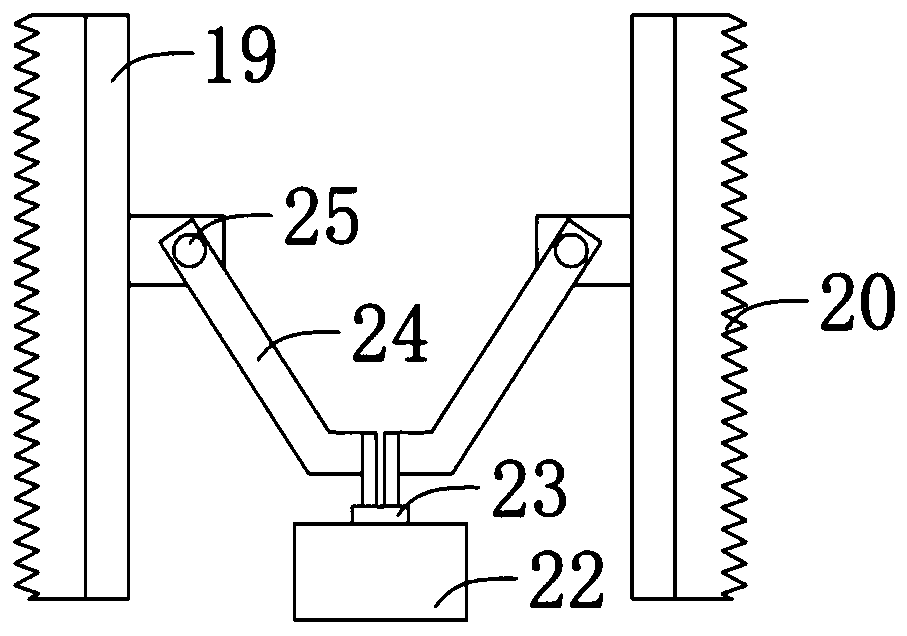

[0039] The present invention provides a variable-diameter drill device, the variable-diameter drill device includes a bracket, a tapered seat 15, a linear drive element and several groups of digging cutter modules; the bracket includes a bottom cover 14, and the tapered seat The bottom surface of 15 is set on the bottom surface of the bottom cover 14; the bottom surface of the linear drive element body is set on the top surface of the bottom cover 14, and the output end of the linear drive element moves in the vertical direction; the several groups of digging tools Each group of digging cutter module in the module group comprises digging cutter 20, tool holder 19 and push rod 24; Said digging cutter 20 is arranged on the outside of said cutter holder 19; The inside of the tool holder 19 is hinged, the other end of the push rod 24 is hinged to the output end of the linear drive element; the bottom of the tool holder 19 is hinged to the bottom cover.

[0040] figure 1 It is a s...

Embodiment 2

[0054] The embodiment of the present invention also provides a kind of digging equipment, referring to the accompanying drawings figure 1 The schematic diagram of the pit digging equipment shown, in order to realize the drive of the variable diameter drill bit device, the pit digging equipment also includes a rotary drive device, the rotary drive device includes a rotating fixed plate 3 and a motor 8, and the motor 8 body is arranged on the On the rotating fixed plate 3, the output end of the motor 8 faces downward, and the output end of the motor 8 is connected to the bracket.

[0055] The rotary driving device also includes a rotating shaft 9, and the rotating shaft 9 transmits the output torque of the motor 8 to the support through the fixed disk 11, so as to drive the variable-diameter drill device to rotate. The bottom surface of the rotating fixed plate is also fixedly connected with three circular inverted L-shaped connecting rods 12 arranged equidistantly. The three in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com