An anti-seepage method for construction of underwater caps in areas with dissolved pores and dissolved pores

A technology for developing areas and dissolving gaps, applied in infrastructure engineering, construction, etc., can solve problems such as high construction cost, poor plugging effect, and long disposal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

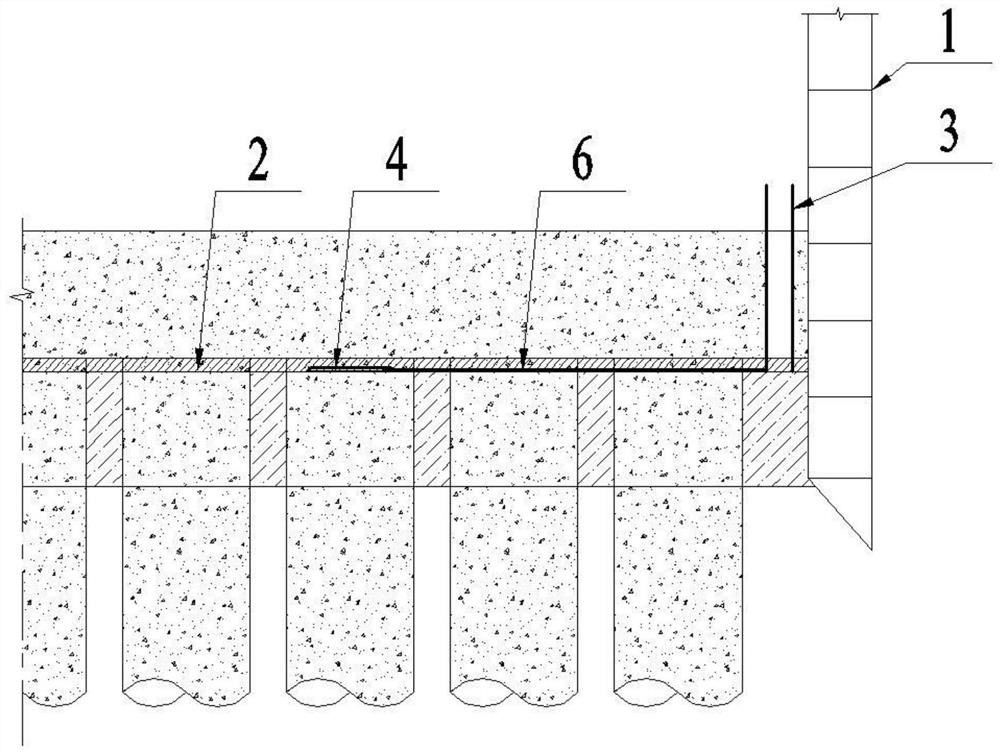

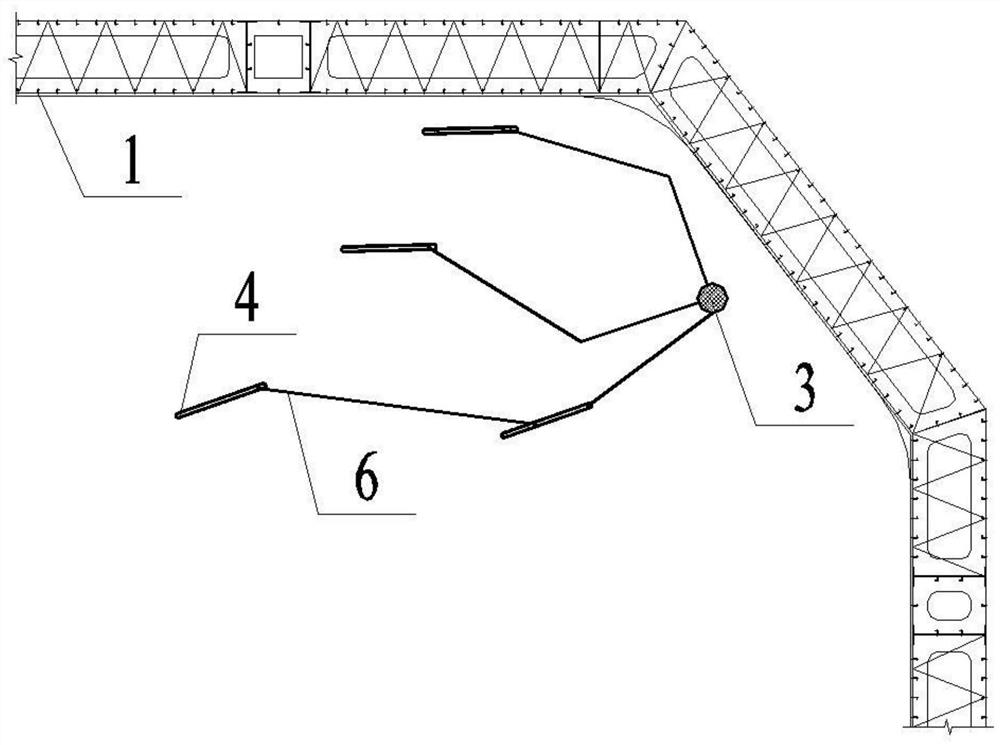

[0026] like Figure 1~3 , this embodiment is used for anti-seepage treatment of the underwater cofferdam. After the cofferdam 1 is put in place, the bottom sealing concrete 2 is poured in the cofferdam 1, and then all the water in the cofferdam 1 is drained to form an environment for dry construction. . Observe the water seepage on the surface of the back-sealing concrete 2, confirm the water seepage point on the back-sealing concrete 2, and start plugging at the water seepage point.

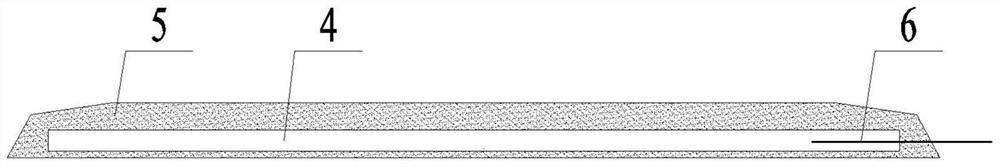

[0027] like Figure 1~3 As shown, the blocking structure of this embodiment is an isolation chamber structure, and the isolation chamber adopts a hollow cover structure with an open lower end. As long as the structure meets this condition, it can meet the requirements of this embodiment. What the isolated bin of this embodiment selects is channel ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com