Filtering device, method for judging its clogging degree, cleaning method and washing machine

A filter device and washing machine technology, applied in the field of washing machines, can solve the problems affecting users' washing use, air duct odor, complex driving device, etc., and achieve the effect of shortening cleaning time and saving water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

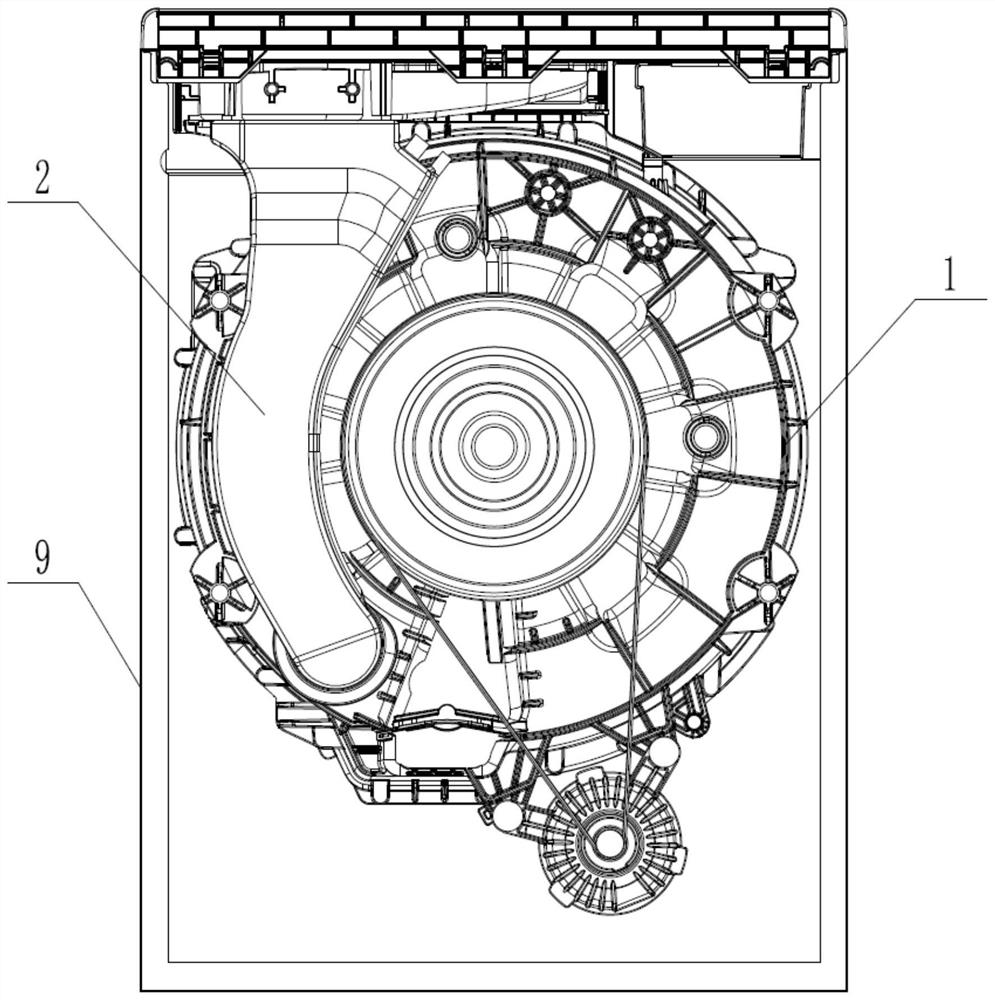

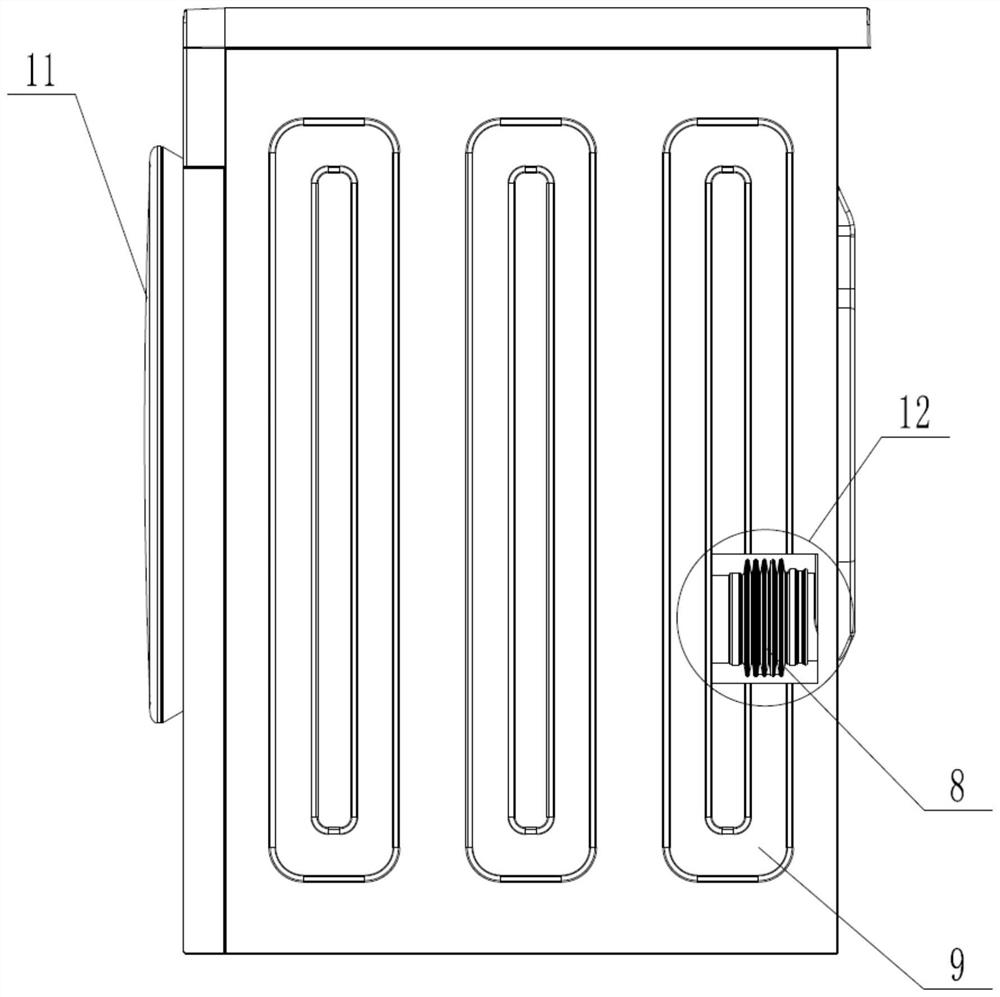

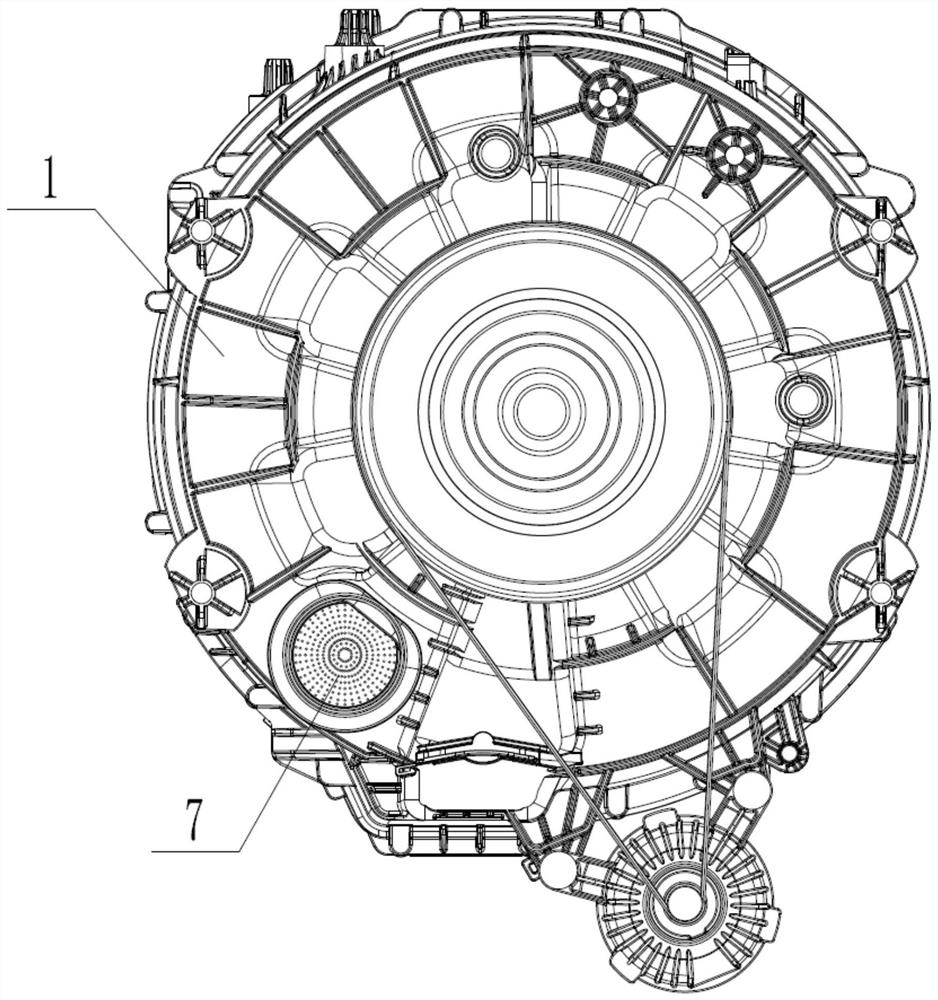

[0049] This embodiment provides a filter device for a drying air duct of a washing machine. Such as figure 1 and figure 2 As shown, the washing machine to which the filter device of the present invention is applied includes a housing part and a drying air duct, wherein the housing part includes a door body 11 and a side plate 9, and the drying air duct includes a condensation end 2, a heating end 3 and a barrel Body 1, a fan system is arranged in the drying air duct. The circulation process of the airflow in the drying air duct is as follows: driven by the work of the fan system, the air in the drying air duct passes through the heating end 3 and is heated to form high-temperature air. The high-temperature air flows through the wet load in the cylinder body 1 and then cools down to become a sub-high temperature The high-humidity air then flows out from the air outlet on the cylinder 1, and then enters the condensing end 2. The sub-high temperature and high-humidity air exch...

Embodiment 2

[0058] This embodiment provides a method for judging the clogging degree of the filtering device, which is used to judge the clogging degree of the filtering device provided in Embodiment 1 of the present application.

[0059] The method specifically includes: before the drying program runs, respectively detecting the static pressure values of the air inlet side of the first filter 4 and the air outlet of the condensing end 2, and judging the clogging degree of the filter device according to the change of the static pressure value, And give feedback to the user, prompting the user to clean or replace the filter device. If the first filter 4 is clogged due to dirt, the flow of the airflow caused by the first is not smooth, which will inevitably cause pressure changes. Generally, the pressure loss between the front and back of the filter, such as the filter screen, is small, and high-precision static pressure testing equipment is needed to ensure Testing the accuracy under low...

Embodiment 3

[0064] This embodiment provides a method for cleaning a filter device used in a drying air duct of a washing machine. Such as Figure 9 As shown, it includes the following steps: using the method for judging the clogging degree of the filter device provided in Example 2 to judge the clogging degree of the filter device; if the user is reminded to clean the filter device, the filter device is cleaned after the drying procedure . Specifically, the method for cleaning the filter device is to remove the first filter 4 and manually clean the first filter 4, if the filter device has a second filter 7, then simultaneously The second filter 7 is removed and the second filter 7 is manually cleaned. In the case where the corresponding position on the side plate 9 is reserved for the disassembly of the first filter 4, the second filter 7 and the hose 8, according to the system prompts, the filter can be manually removed from the side of the unit for maintenance. Flushing, its efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com