Preparation method of a slow-release degradable film-coated porous material of fertilizer

A porous material and degradable film technology, applied in the field of porous material preparation, can solve the problems of variation and other biological pollution, high cost of graphene, complicated process, etc., and achieve the effect of prolonging the effective release period, increasing the retention time, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

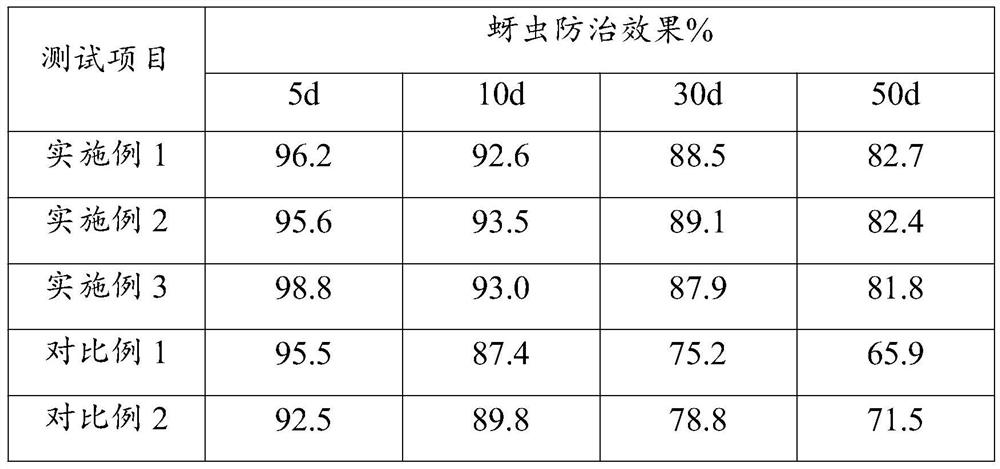

Embodiment 1

[0041] 1. Preparation of porous carbonized material:

[0042] 1) Weigh plant ash as raw material, dry at 70°C for 2 hours, mechanically pulverize, pass through a 10-mesh sieve, and superfinely pulverize through a 250-mesh sieve for later use;

[0043] 2) Weighing 45wt% of plant ash powder in proportion, 35wt% of a configured mass fraction of 8% potassium hydroxide alkali solution, and 20wt% of pore-enhancing agent 15% polyvinylpyrrolidone;

[0044] 3) Soak the pulverized plant ash in the mixed solution for 5 hours, put it into the drier for ammoniation and dispersion treatment with ammonia gas for 1 hour;

[0045] 4) Put the plant ash powder into the tube furnace for low-temperature carbonization, set the temperature to rise from 100°C / h to 300°C for 3 hours, during which the protective gas nitrogen is introduced, cooled to room temperature and taken out for later use.

[0046] 2. Pesticide loading of porous materials:

[0047] 1) Weigh 1500ml of 20% sodium pentachlorophenat...

Embodiment 2

[0059] 1. Preparation of porous carbonized material:

[0060] 1) Weigh plant ash as raw material, dry at 70°C for 2.5 hours, mechanically pulverize, pass through a 10-mesh sieve, and superfinely pulverize through a 250-mesh sieve for later use;

[0061] 2) Weigh 60wt% of plant ash powder in proportion, 30wt% of the configured mass fraction 8% potassium hydroxide alkali solution, and 10wt% of pore-enhancing agent 3% urea solution;

[0062] 3) Soak the pulverized plant ash in the mixed solution for 5 hours, put it into the drier for 1.5 hours for ammonification and dispersion treatment with ammonia gas;

[0063] 4) Put the plant ash powder into the tube furnace for low-temperature carbonization, set the temperature to rise from 100°C / h to 300°C for 3 hours, during which the protective gas nitrogen is introduced, cooled to room temperature and taken out for later use.

[0064] 2. Pesticide loading of porous materials:

[0065] 1) Weigh 1500ml of 20% sodium pentachlorophenate aq...

Embodiment 3

[0077] 1. Preparation of porous carbonized material:

[0078] 1) Weigh plant ash as raw material, dry at 73°C for 2 hours, mechanically pulverize, pass through a 10-mesh sieve, and superfinely pulverize through a 250-mesh sieve for later use;

[0079] 2) Weighing 55wt% of the plant ash powder in proportion, 30wt% of the configured mass fraction 8% potassium hydroxide alkali solution, and 15wt% of the pore-enhancing agent 3% urea solution;

[0080] 3) Soak the pulverized plant ash powder in the mixed solution for 5.5 hours, wash it with a large amount of distilled water until the pH value is 7-9, and put it into the dryer for 1.5 hours of ammonification and dispersion treatment with ammonia gas;

[0081] 4) Put the plant ash powder into the tube furnace for low-temperature carbonization, set the temperature to rise from 100°C / h to 300°C for 3 hours, during which the protective gas nitrogen is introduced, cooled to room temperature and taken out for later use.

[0082] 2. Pesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com