Method for producing recycled aggregates by taking sorted decoration wastes as raw materials

A technology for recycled aggregate and decoration waste, which is used in the production of recycled aggregate and garbage disposal. It can solve the problems of high crushing value, low strength, and large difference in water absorption, and achieve the effect of improving the water absorption index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

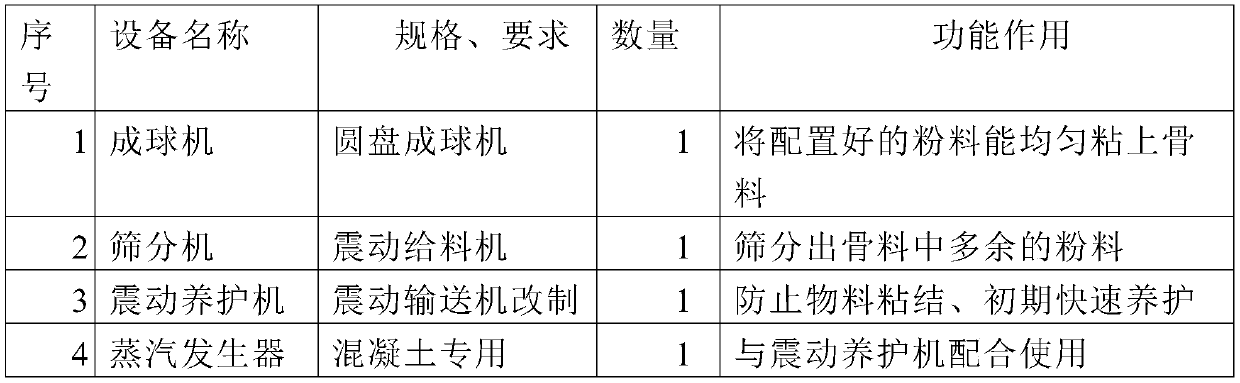

Image

Examples

Embodiment Construction

[0022] A method for producing regenerated aggregates from sorted decoration wastes. After crushing, the surface of the aggregates with a particle size of 5-15mm and 15-30mm is wrapped with a layer of configured cement paste and fully cured. Finally, a lightweight recycled aggregate is formed. The specific steps are:

[0023] 1. Use the sorted decoration waste as raw material, and soak the crushed aggregate with a particle size of 5-15mm and 15-30mm in water to make it fully absorb water;

[0024] 2. Stir and mix R-type ordinary Portland cement and dry fly ash at a weight ratio of 1:1-2 to obtain powder;

[0025] 3. Put the above-mentioned water-soaked aggregate and the prepared powder into the rotating ball forming machine continuously at a weight ratio of 1:0.1-0.15. Since the aggregate contains moisture, the prepared powder can be absorbed on the surface. The body material forms an adhesive layer, and the strength of the adhesive layer is enhanced during the rotation of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com