A comprehensive utilization method and utilization system of sludge multi-stage resource utilization

A recycling and sludge technology, applied in chemical instruments and methods, separation methods, sludge treatment, etc., can solve the problems of heavy metal secondary pollution, large investment, high sand content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

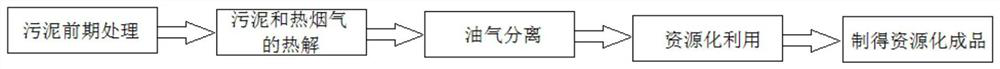

[0032] see figure 1 , a method for comprehensive utilization of sludge multi-stage recycling, comprising the following steps:

[0033] (1) Pre-treatment of sludge: adding polyferric sulfate to the sludge to destroy the floc structure in the sludge, the addition of polyferric sulfate is 5-7% of the total mass of the sludge, and then undergoes dehydration treatment; using natural Zeolite or artificial zeolite adsorbs impurities in the odor released during the sludge dehydration process, and the tail gas after adsorption reaches the standard discharge;

[0034] (2) Pyrolysis of sludge and hot flue gas: The hot flue gas from the kiln is contacted with the sludge treated in step (1) downstream, and the sludge particles absorb heat and are pyrolyzed under anoxic conditions to produce tar, pyrolysis gas and sludge coke;

[0035] (3) Oil and gas separation: The oil and gas produced by pyrolysis are separated, and the separated pyrolysis gas flows out through the dust removal unit, a...

Embodiment 2

[0047] see figure 1 , a method for comprehensive utilization of sludge multi-stage recycling, comprising the following steps:

[0048] (1) Pre-treatment of sludge: adding polyferric sulfate to the sludge to destroy the floc structure in the sludge, the addition of polyferric sulfate is 5-7% of the total mass of the sludge, and then undergoes dehydration treatment; using natural Zeolite or artificial zeolite adsorbs impurities in the odor released during the sludge dehydration process, and the tail gas after adsorption reaches the standard discharge;

[0049] (2) Pyrolysis of sludge and hot flue gas: The hot flue gas from the kiln is contacted with the sludge treated in step (1) downstream, and the sludge particles absorb heat and are pyrolyzed under anoxic conditions to produce tar, pyrolysis gas and sludge coke;

[0050] (3) Oil and gas separation: The oil and gas produced by pyrolysis are separated, and the separated pyrolysis gas flows out through the dust removal unit, a...

Embodiment 3

[0068] see figure 1 , a method for comprehensive utilization of sludge multi-stage recycling, comprising the following steps:

[0069] (1) Pre-treatment of sludge: adding polyferric sulfate to the sludge to destroy the floc structure in the sludge, the addition of polyferric sulfate is 5-7% of the total mass of the sludge, and then undergoes dehydration treatment; using natural Zeolite or artificial zeolite adsorbs impurities in the odor released during the sludge dehydration process, and the tail gas after adsorption reaches the standard discharge;

[0070] (2) Pyrolysis of sludge and hot flue gas: The hot flue gas from the kiln is contacted with the sludge treated in step (1) downstream, and the sludge particles absorb heat and are pyrolyzed under anoxic conditions to produce tar, pyrolysis gas and sludge coke;

[0071] (3) Oil and gas separation: The oil and gas produced by pyrolysis are separated, and the separated pyrolysis gas flows out through the dust removal unit, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com