Grey fabric winding and detection facility

A detection equipment and technology for grey fabrics, which are applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problem of poor detection effect and winding quality of grey fabrics, inability to ensure the smooth surface of grey fabrics, and troublesome roll removal and roll replacement. and other problems, so as to improve the detection effect, improve the winding quality, and facilitate maintenance and repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

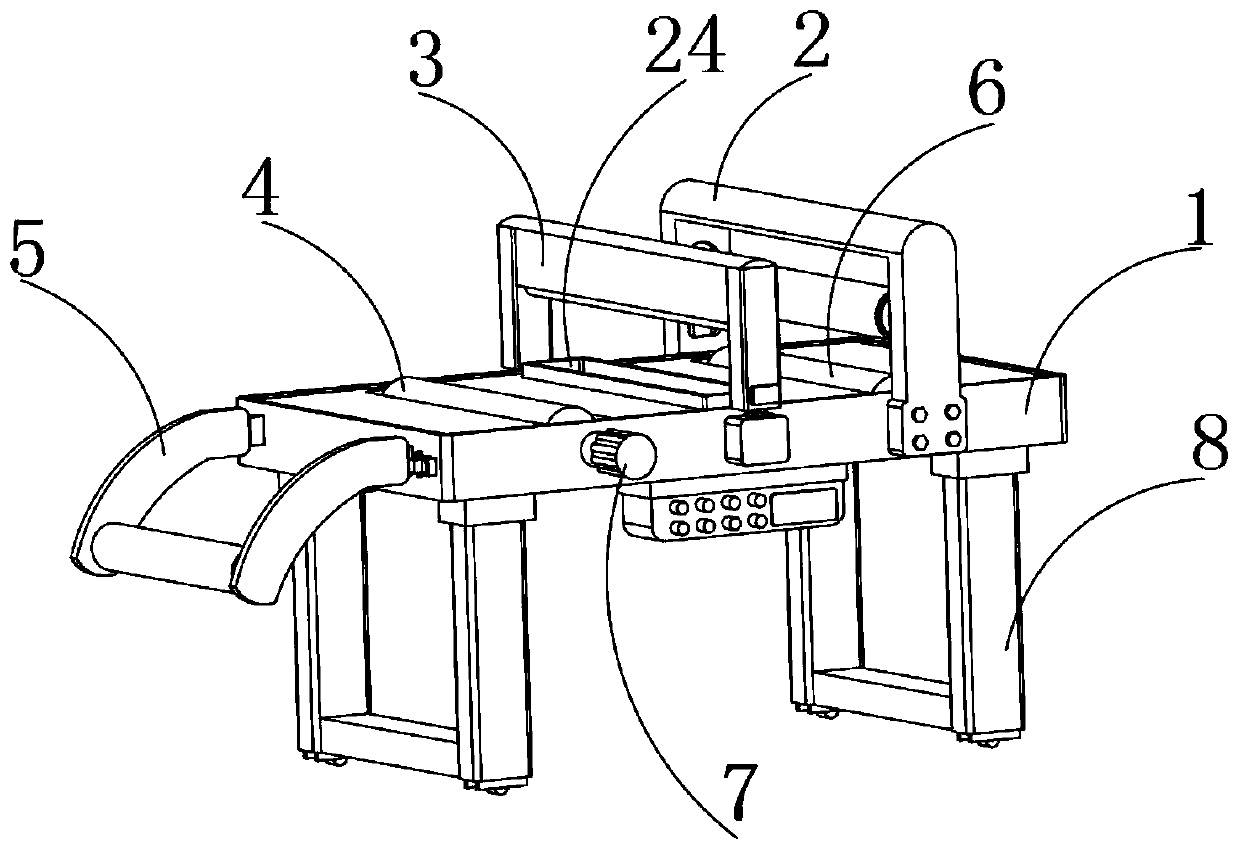

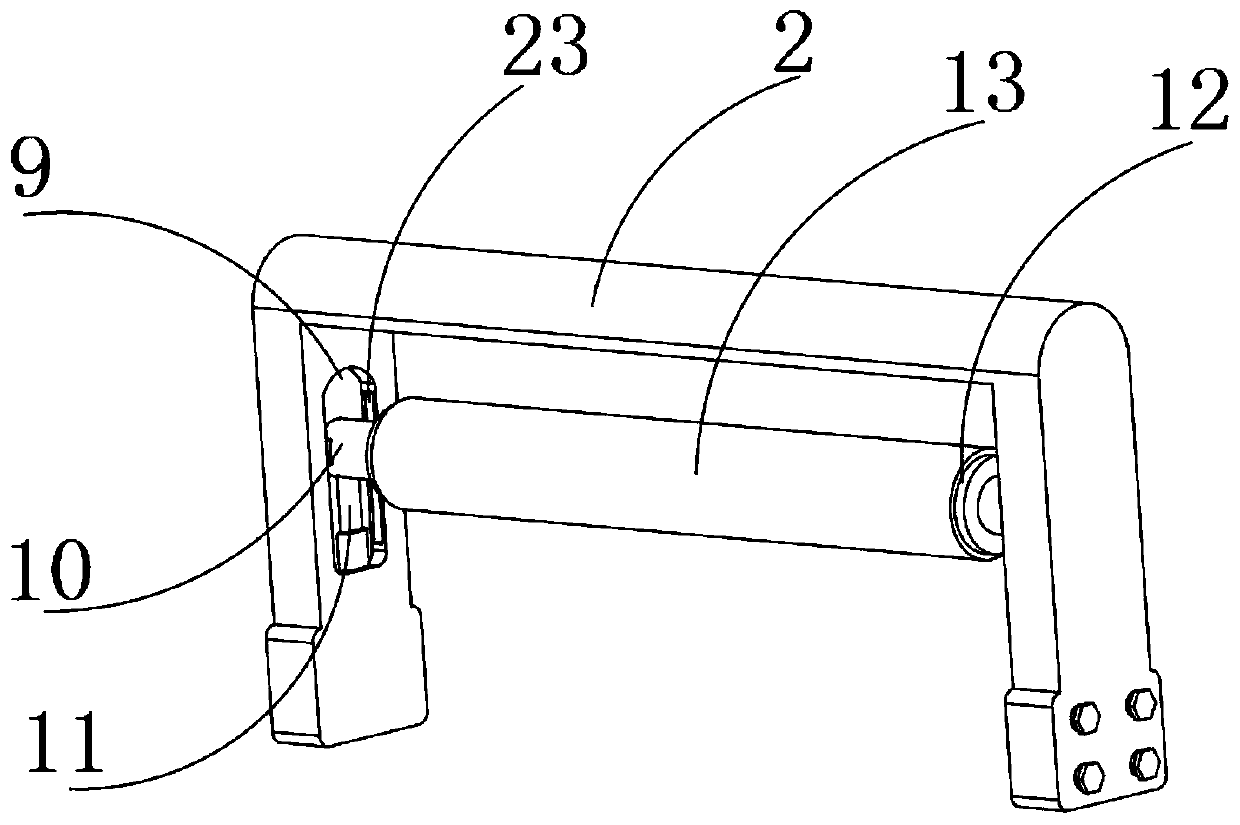

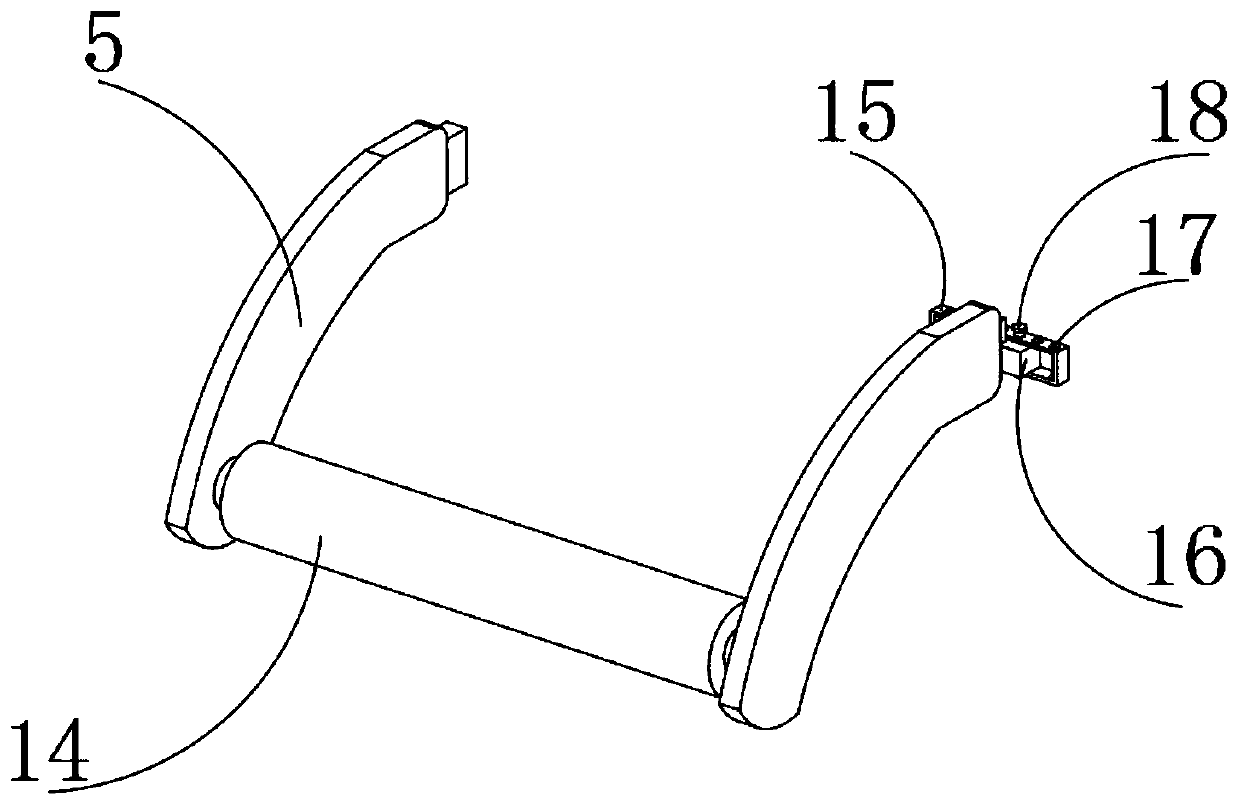

[0024] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, gray cloth winding detection equipment, including a cloth table 1, a wrinkle removal bracket 2 is installed on the top side of the cloth table 1, a detection bracket 3 is installed on one side of the wrinkle removal bracket 2, and the cloth table 1 The ultraviolet detection board 24 is embedded in the corresponding detection bracket 3, and an ultraviolet detection card is installed inside the ultraviolet detection board 24. The ultraviolet light is irradiated to the ultraviolet detection card, so that the ultraviolet detection card is discolored, and the anti-ultraviolet performance of the gray cloth can be detected. The ultraviolet detection card is conveniently replaced by the ultraviolet detection plate 24. The outer side of the cloth table 1 is equipped with a winding support 5, the inner side of the cloth table 1 is embedded with a guide roller 4, and one end of the guide rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com