Rigid-flexible coupling self-adaptive bucket wheel device

A rigid-flexible coupling, self-adaptive technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problem of the bucket wheel easily colliding with the ground rigidly, so as to improve the operation efficiency, efficiently reclaim and clear the site, and increase the opening rate. The effect of the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

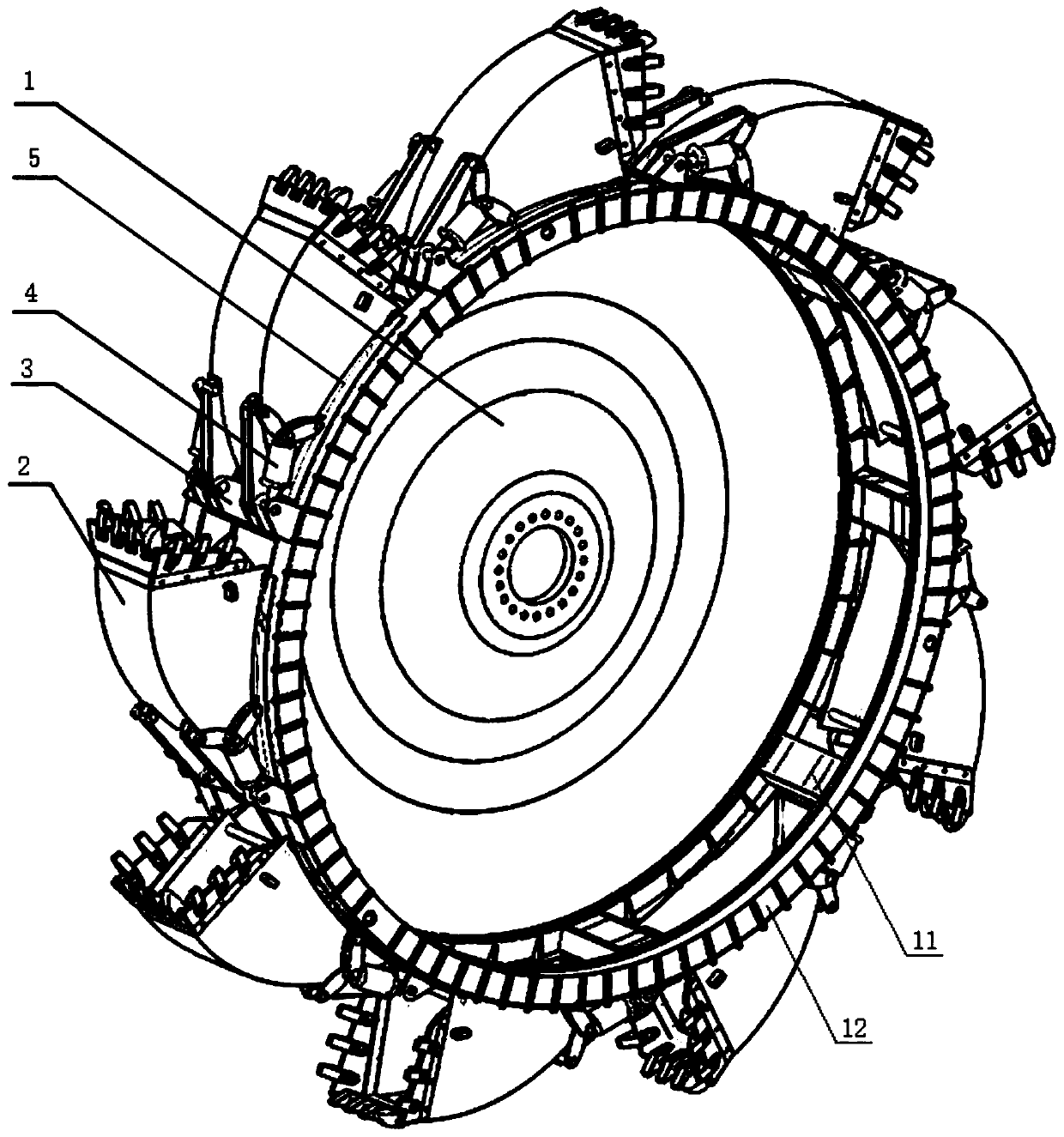

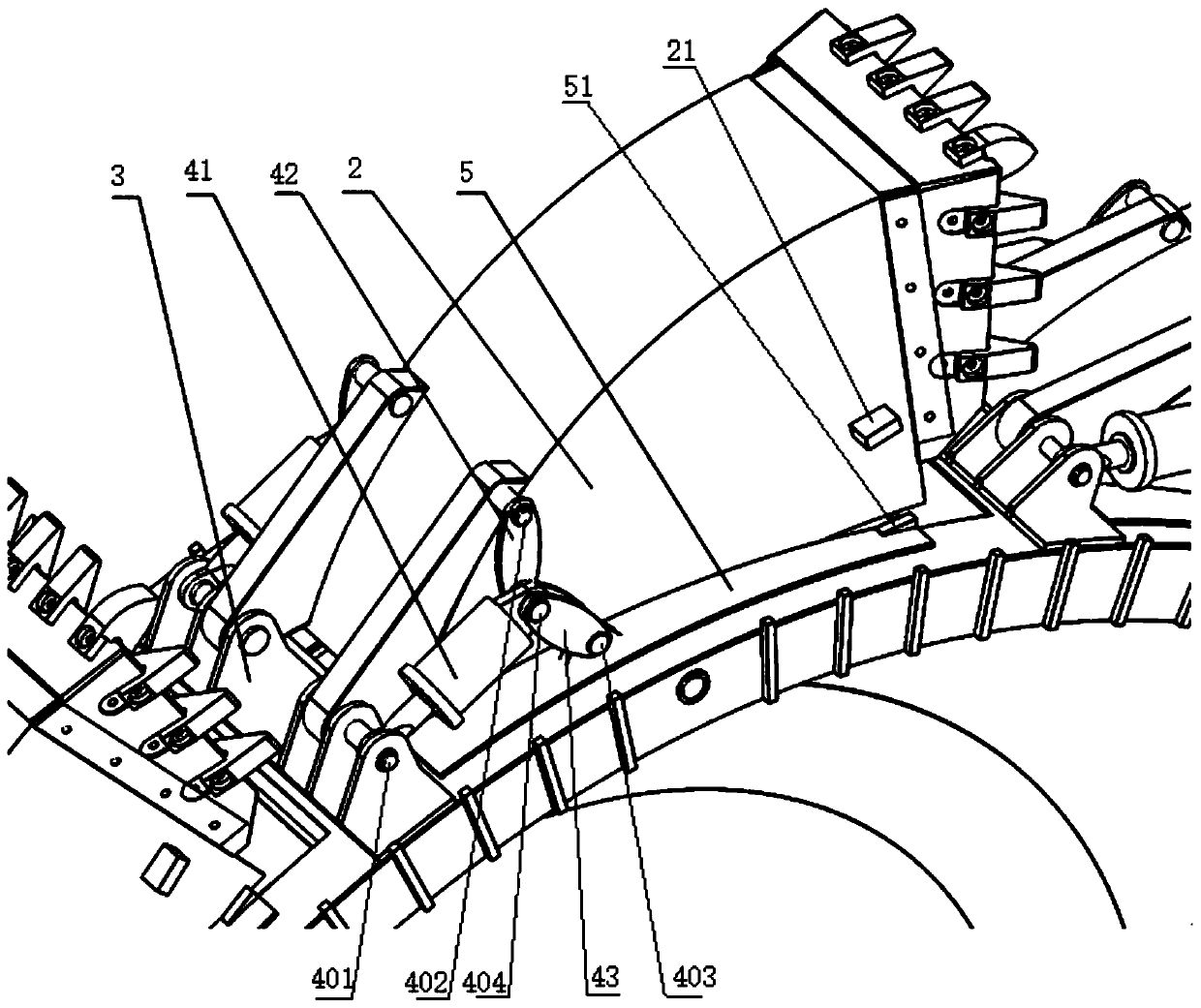

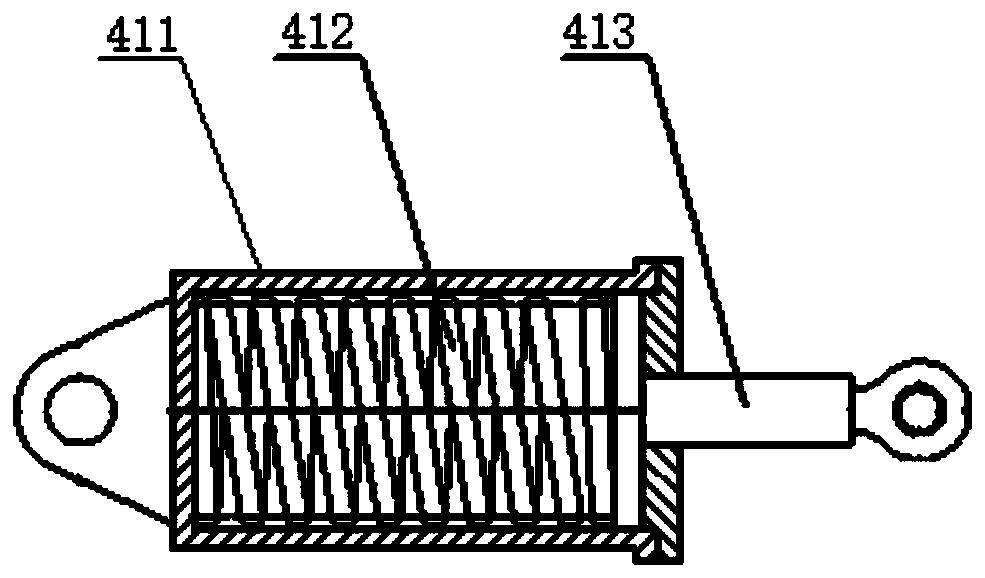

[0020] In order to solve the technical problem that the bucket wheel and the loader need to work together to complete the material clearance work in the existing reclaiming operation, and the bucket wheel is easy to collide with the ground rigidly during the operation. Embodiment 1 of the present invention provides a rigid-flexible coupling adaptive bucket wheel device, such as figure 1 As shown, it includes hoppers 2 evenly distributed on the body of the bucket wheel 1 in a circumferential direction. The width of the bucket body of the hopper 2 is smaller than the distance between the two longitudinal beams 12 of the bucket wheel 1. Such as figure 1 with figure 2 As shown, the beam 11 of the bucket wheel 1 is provided with a rotating base 3, and the bottom end of the hopper 2 is hinged on the rotating base 3. At the same time, the bucket body of the hopper 2 is symmetrically provided with a telescopic connection. The rod part 4 forms a flexible connection with the two longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com