Differential steering mechanism and steering control method of automatic conveying trolley

A technology of automatic conveying and differential steering, applied in electric steering mechanism, power steering mechanism, steering mechanism, etc., can solve the problems of large friction and wear of wheels, high stability requirements, poor steering and other problems, so as to reduce friction and wear, Improves spirituality and reduces friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

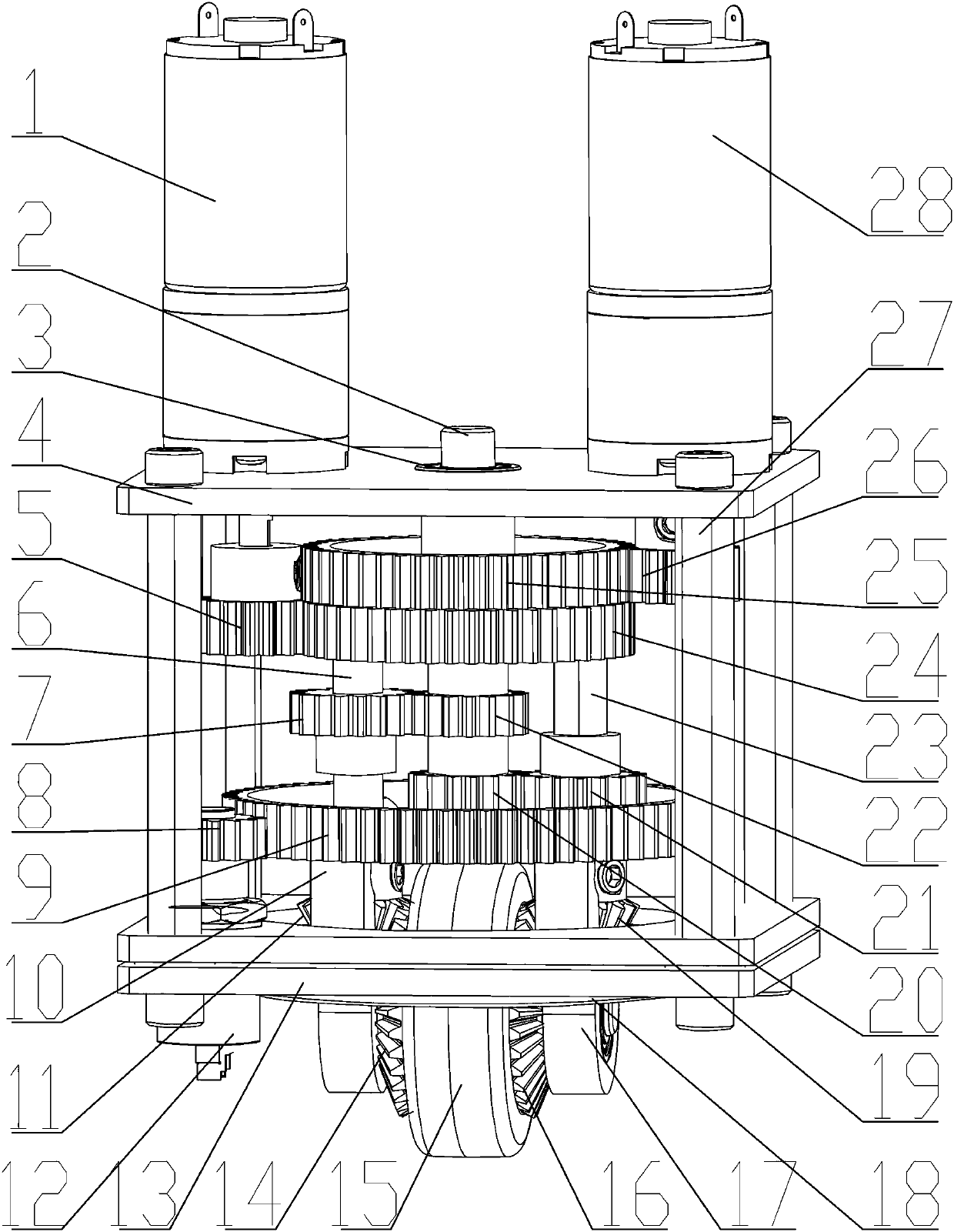

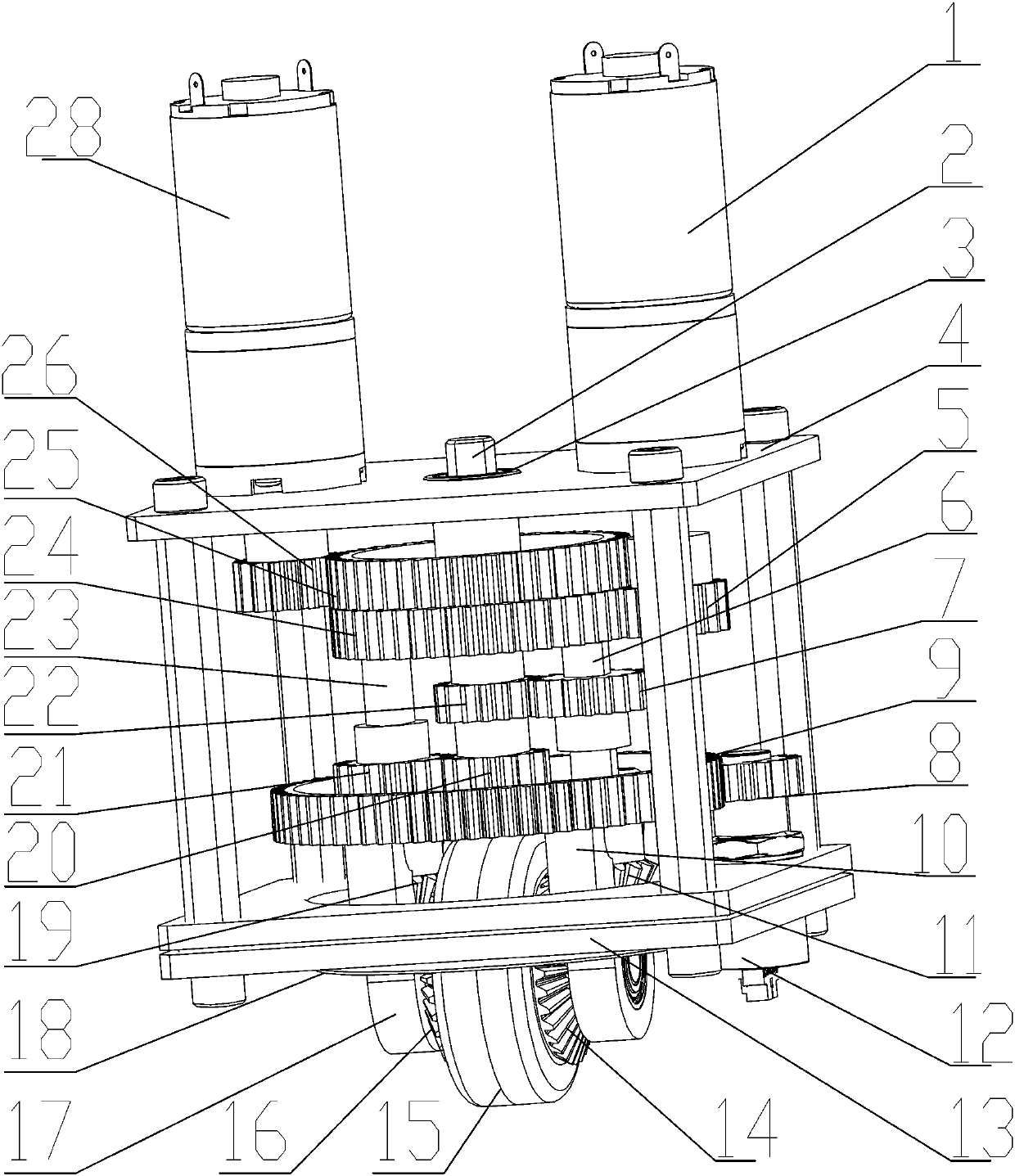

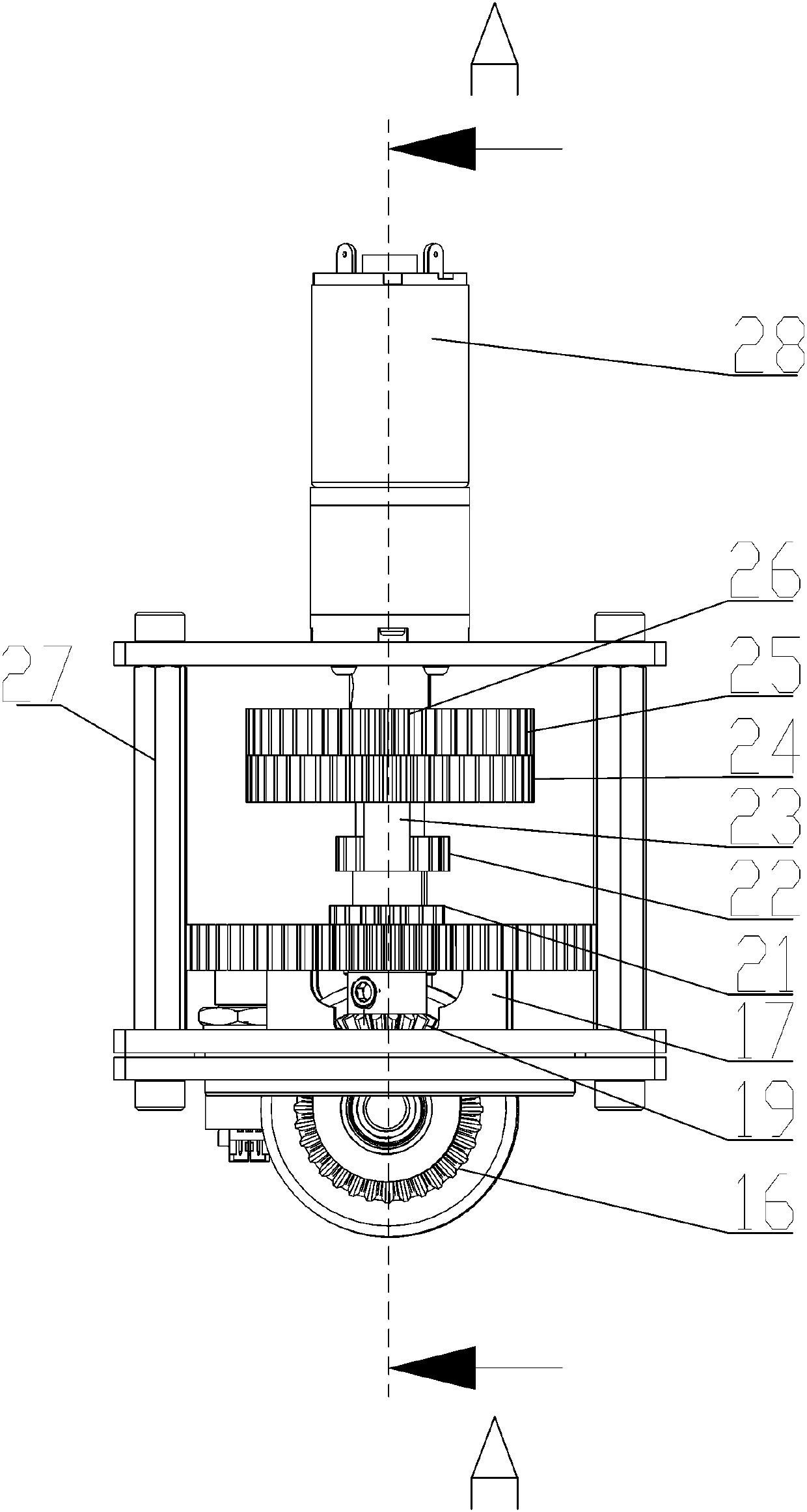

[0029] see Figure 1-4 , the differential steering mechanism of the automatic conveying trolley, which includes a base plate 13, the top four corners of the base plate 13 are supported and installed with a top plate 4 by a plurality of support columns 27, a rotating disc 18 is installed at the center of the base plate 13, and the rotating disc 18 is installed at the center of the base plate 13. A first wheel frame plate 17 and a second wheel frame plate 10 arranged in parallel are symmetrically installed on the disc 18, and a wheel 15 is supported and installed between the first wheel frame plate 17 and the second wheel frame plate 10 by a wheel shaft 29. The first wheel frame plate 17 and the top of the second wheel frame plate 10 are fixedly installed with the first gear plate 9 by locking bolts, and the first driven bevel gear 16 is installed on the wheel shaft 29 and on one side of the wheel 15, On its other side, the second driven bevel gear 14 is installed, and the first...

Embodiment 2

[0038] The steering control method of the differential steering mechanism of any one of the automatic conveying trolleys, when turning is required, by controlling the rotating speeds of the first motor 28 and the second motor 1 to cause a speed difference, the rotation of the first motor 28 The first gear 26 will be driven, and then the second gear 25 will be driven by the first gear 26, and the second gear 25 will drive the central shaft 2, and the third gear 20 will be synchronously driven by the central shaft 2, and then the third gear 20 will drive the fourth gear. The gear 21 drives the first vertical shaft 23 through the fourth gear 21, and then the first driving bevel gear 19 is driven by the first vertical shaft 23, and the first driving bevel gear 19 is meshed with the first driven bevel gear 16 to drive the wheels 15 The inner axle 29 rotates at a speed A;

[0039] The rotation of the second motor 1 will drive the fifth gear 5, then the fifth gear 5 drives the sixth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com