Forming mold facilitating mold release

A molding die and demoulding technology, applied in the field of molding die that is easy to demould, can solve the problems of scratching the wall surface, polluting the product environment, etc., and achieve the effects of rapid demoulding, improving smoothness, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

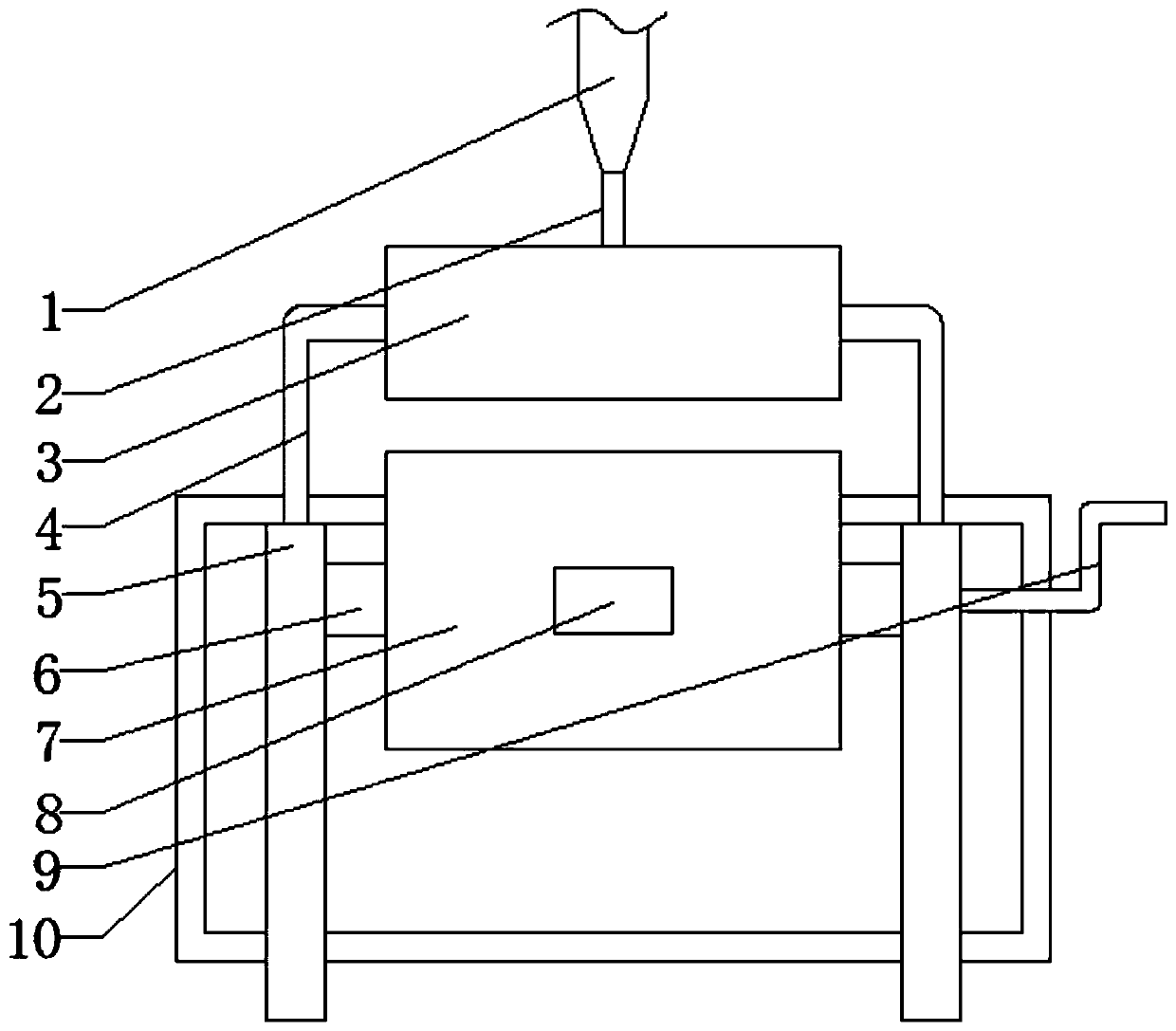

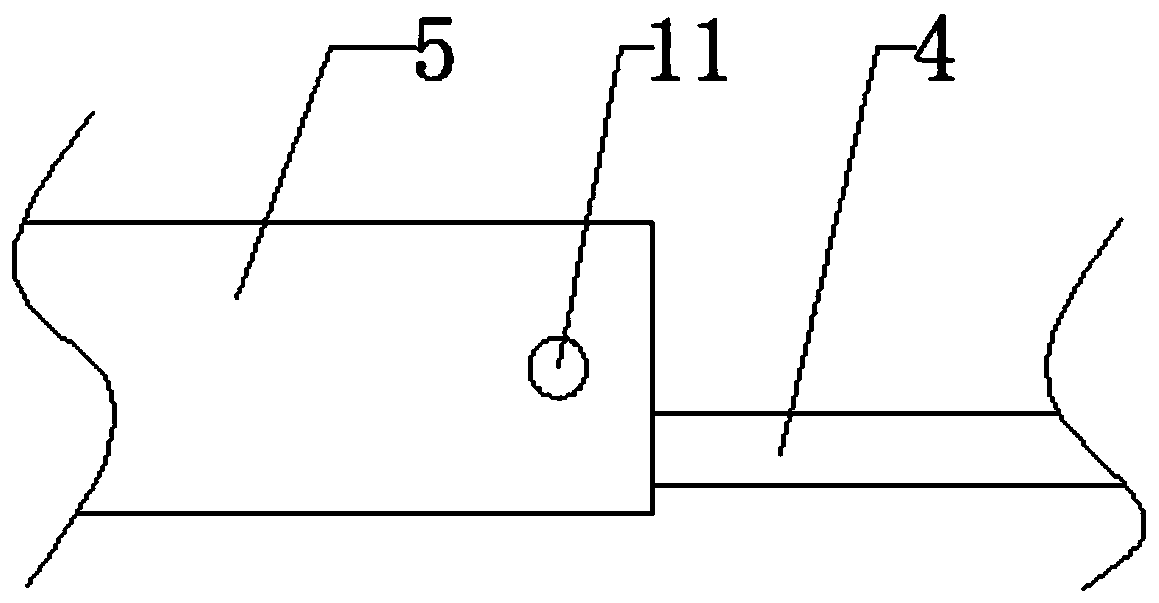

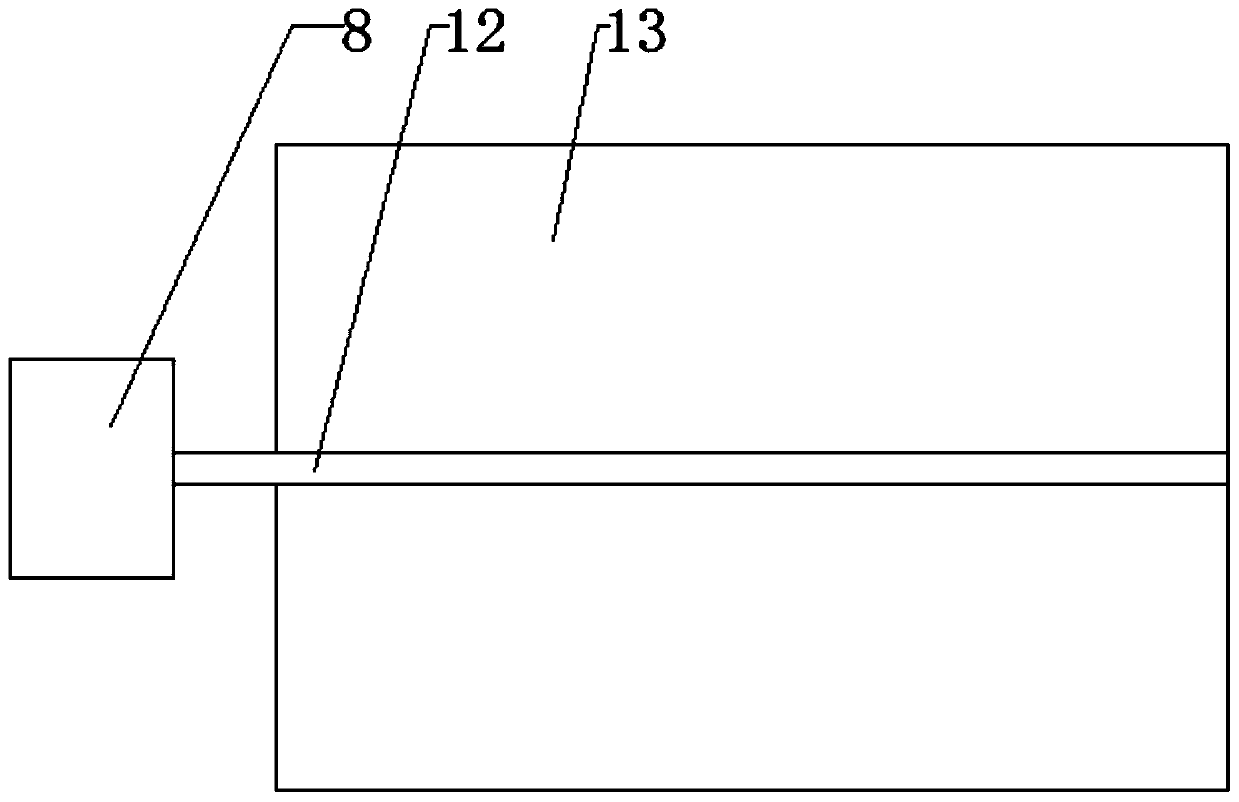

[0034] see Figure 1-3 , a molding mold for easy demoulding, comprising an injection molding device 1, the injection molding device 1 is a screw injection molding device, the outer wall of the injection molding device 1 is coated with heat-insulating material, and the output end of the injection molding device 1 is connected with an injection molding pipeline 2, The end of this injection molding pipeline 2 is connected with upper mold 3, and injection mold cavity is installed in upper mold 3, and injection pipeline 2 is fixedly installed on the upper mold 3 by screw connection, and injection pipeline 2 communicates with injection mold cavity, in upper mold Both ends of 3 are fixedly connected with a guide rod 4, the outside of the guide rod 4 is sleeved with a rod tube 5, the opening end of the rod tube 5 is equipped with a limit ring, and the end of the guide rod 4 is connected with a limit block, the limit block Located between the limit ring and the bottom wall of the rod t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com