Size adjustability type multi-layer reinforcing mesh high-accuracy machining bed-jig and application method

A technology of high-precision processing and steel mesh, applied in the field of construction engineering, can solve the problems of non-reuse, high cost allocation, poor adjustability, etc., and achieve the effect of reducing procurement costs and waste of resources, reducing cost allocation, and improving production flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

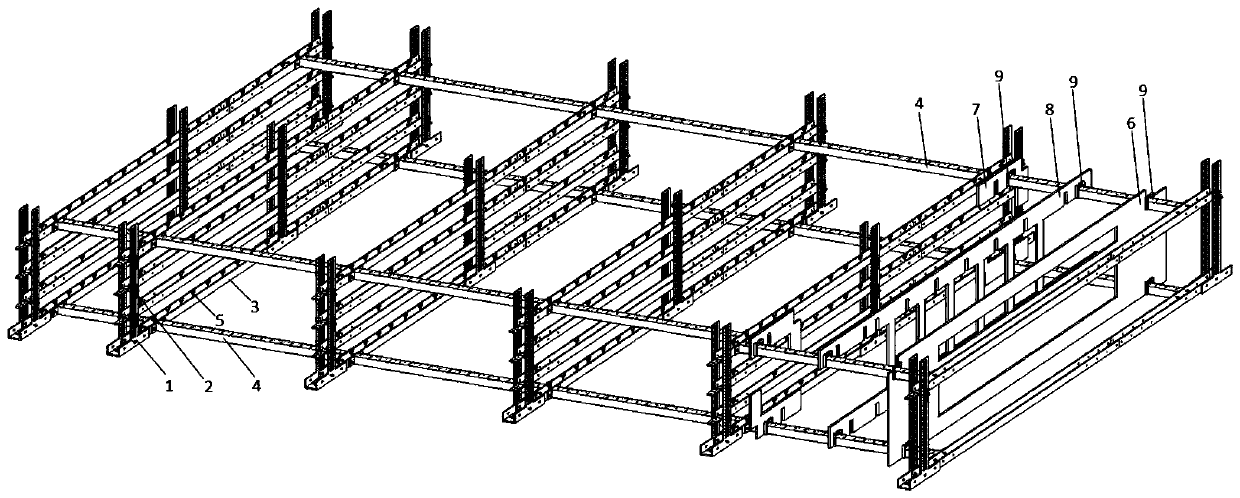

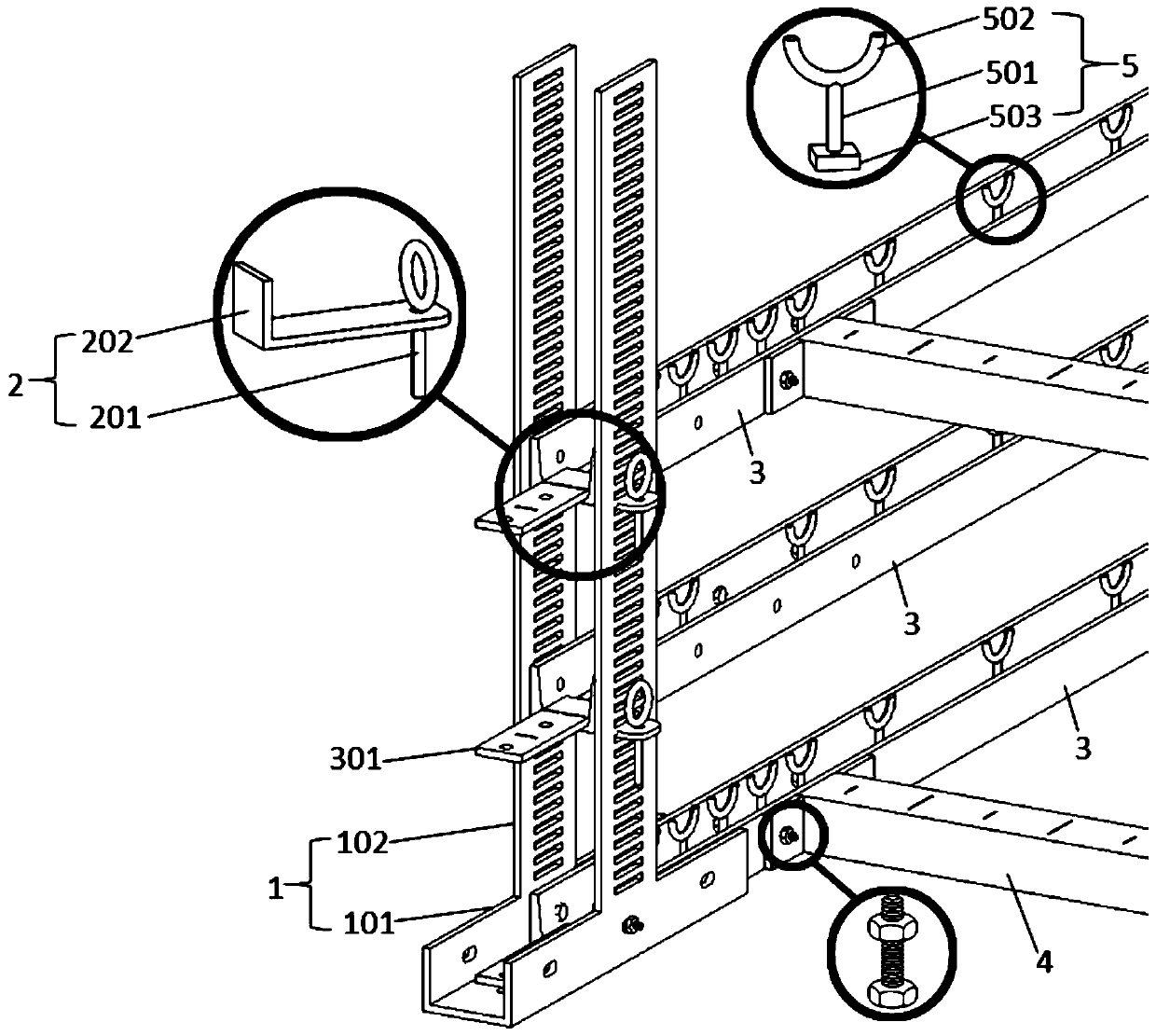

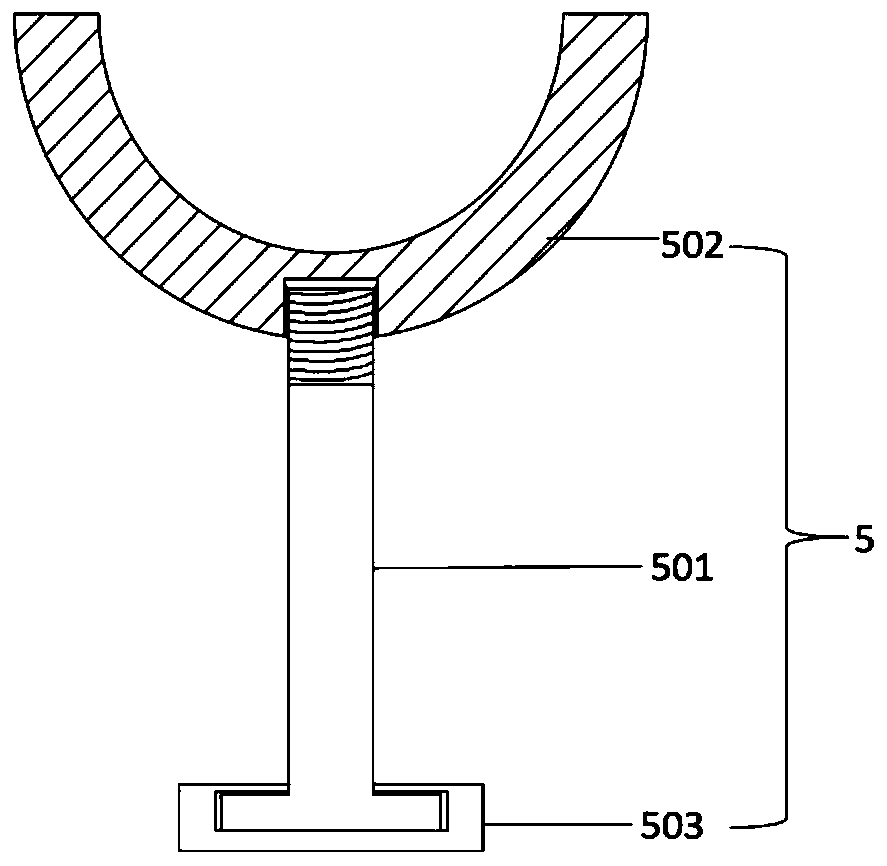

[0065] Such as figure 1 , 2 , a size-adjustable multi-layer steel mesh high-precision processing tire frame, including several vertical supports 1, beam support components 2, beams 3, longitudinal beams 4, longitudinal rib limiters 5, and a long longitudinal rib limiter plate 6 and four short longitudinal rib limit plates 7; the several vertical supports 1 are arranged in a rectangular array, and a single vertical support 1 is composed of a channel steel 101 and two vertical plates 102; the two vertical supports The two vertical plates 102 are integrally formed with the two wings of the channel steel 101 respectively, and extend vertically along the opening direction of the channel steel 101. The two vertical plates 102 are provided with a number of strip-shaped holes corresponding to each other at equal intervals in the vertical direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com