Silicon rubber transfusion heating heat-insulating pipe and manufacturing method thereof

A technology of heating and heat preservation and a production method, which is applied in the field of medical tools, can solve problems such as length and distance limitations of infusion tube fluid, difficulty in recovering metal materials from deformation, and influence of electric energy and service life, etc., and achieves good heating stability, remarkable heat preservation effect, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

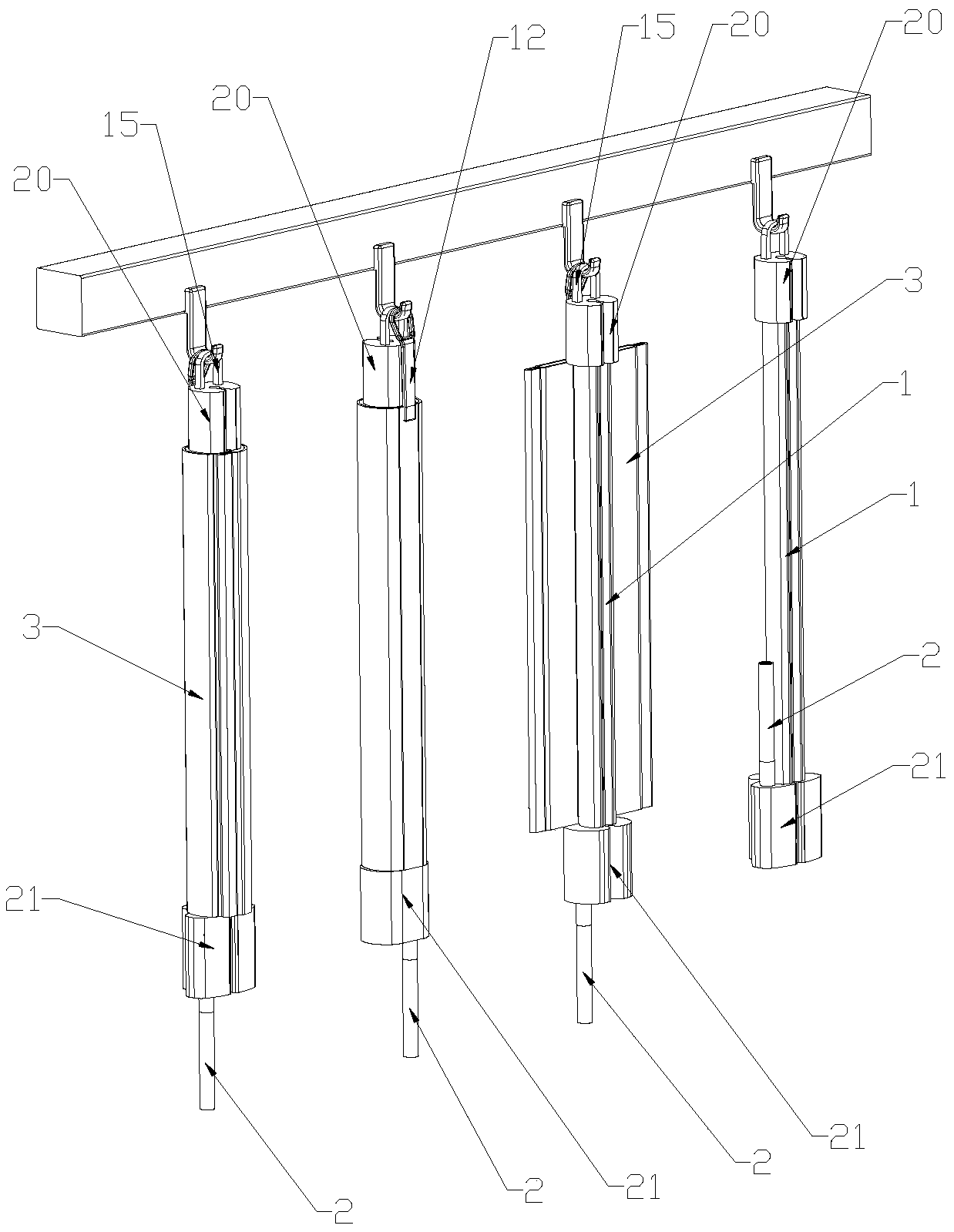

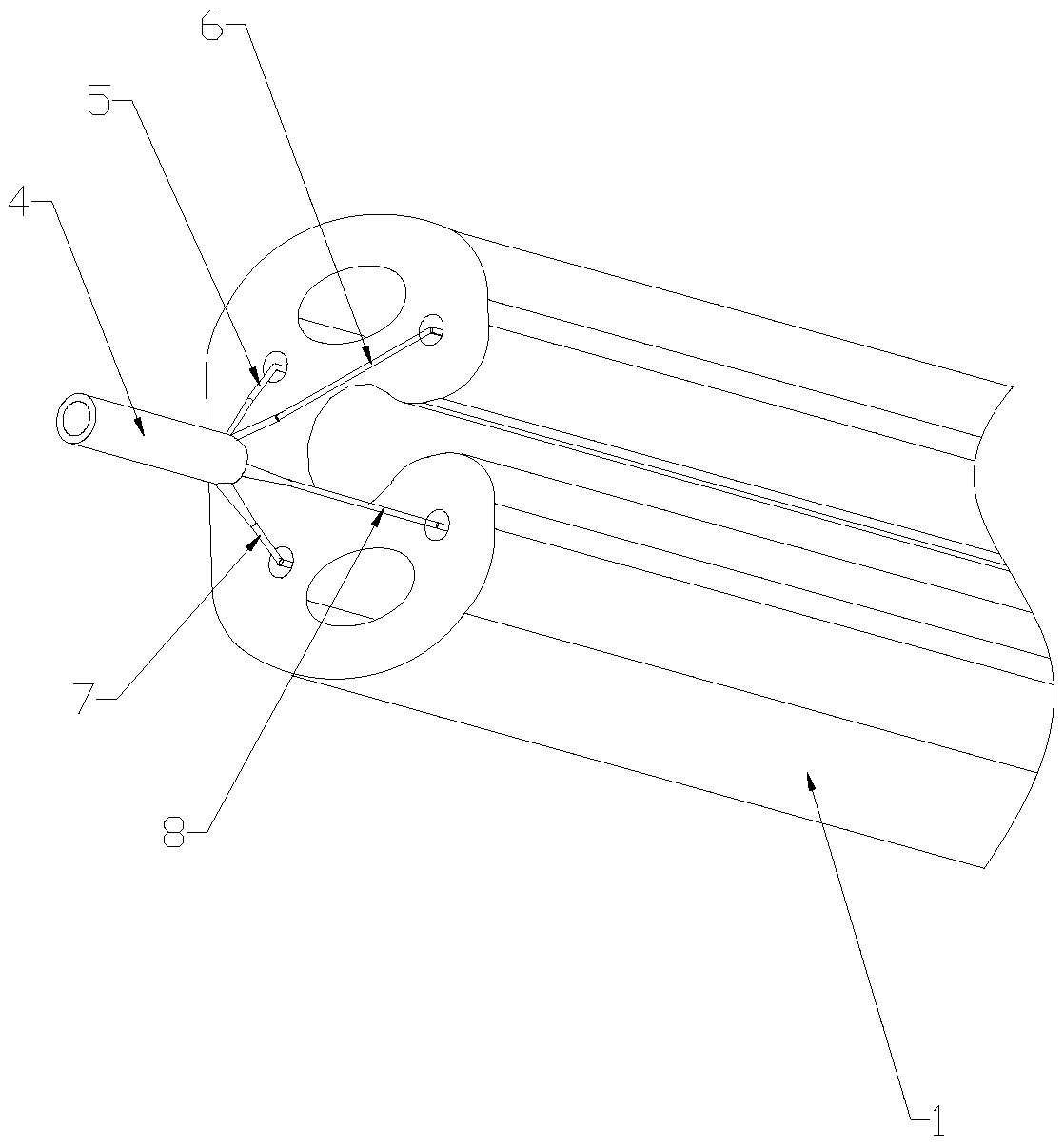

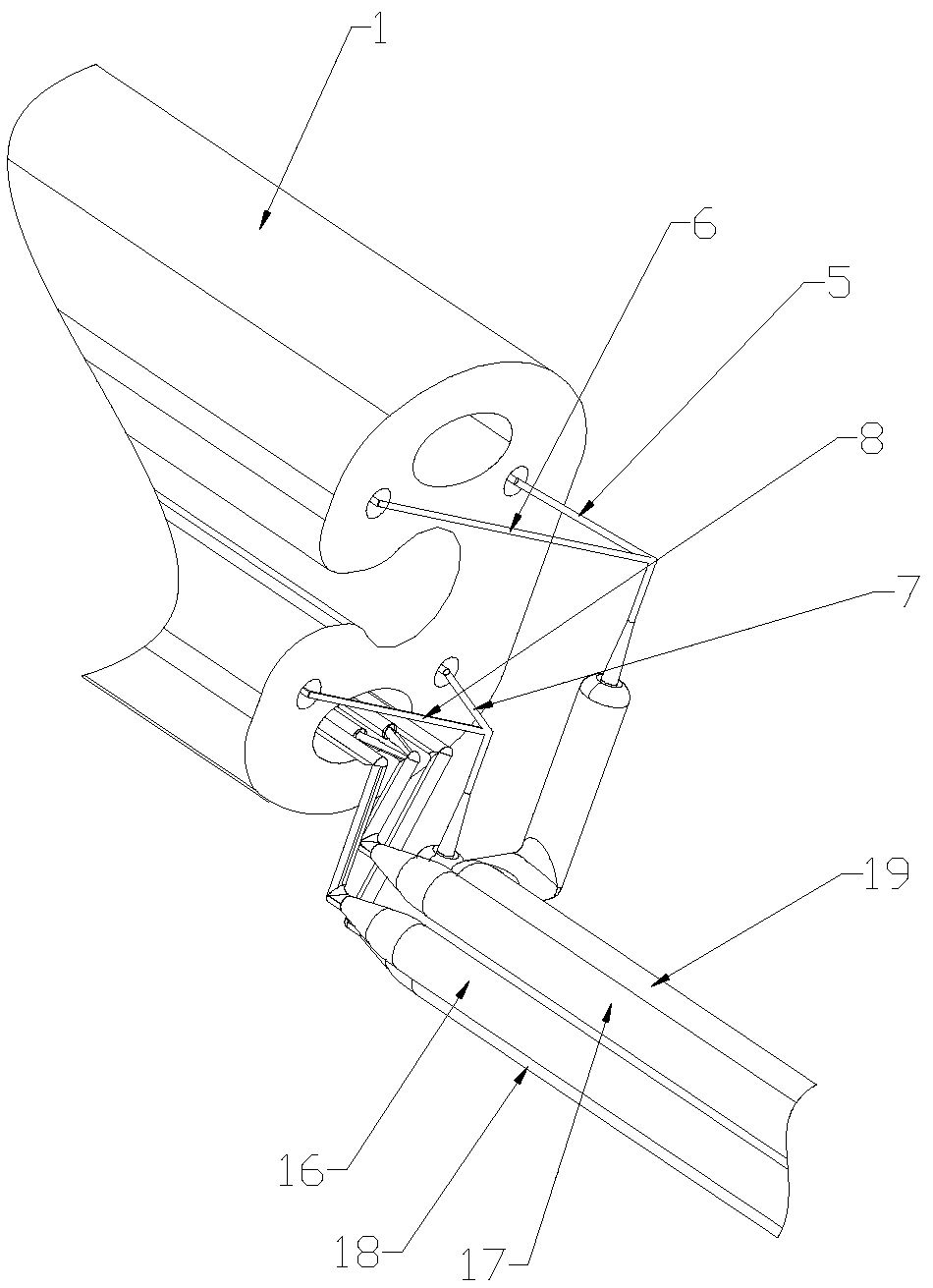

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0043] like Figure 1 to Figure 5As shown, in this embodiment, a silicone rubber infusion heating insulation tube includes a silicone rubber heating tube middle tube 1, a power supply cable 2, a heat preservation sleeve 3, an insulating high-temperature heat-shrinkable tube 4, and a first composite fiber heating wire 5. The second composite fiber heating wire 6, the third composite fiber heating wire 7, the fourth composite fiber heating wire 8, the first NTC temperature sensor 9, the second NTC temperature sensor 10, the foamed liquid silicone rubber 11, the first flexible The magnetic sheet 13 and the second flexible magnetic sheet 14, the first wire 16, the second wire 17, the third wire 18, the fourth wire 19 and the fifth wire are arranged in the power cable 2, the power cable 2 Connected to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com