Fermentation method of pure walnut fermented milk

A fermentation method and technology for fermenting milk, applied in milk substitutes, dairy products, Lactobacillus and other directions, can solve the problems of long fermentation time, complicated fermentation process, long time consumption, etc., achieve a good growth and fermentation environment, reduce fermentation time, The effect of preventing excessive deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

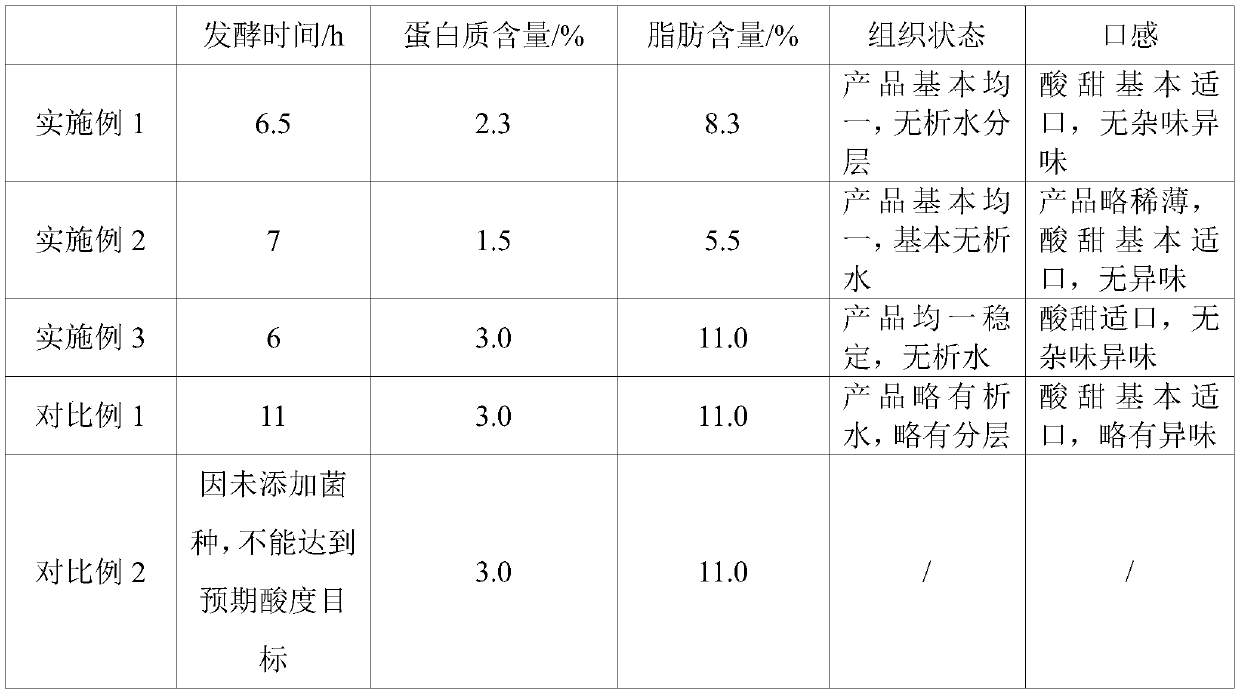

Embodiment 1

[0043] The present embodiment provides a kind of fermentation method of pure walnut fermented milk, described method comprises:

[0044] Enzymolytic fermentation: mix the pretreated fermentation base material with neutral protease, and then add fermentation strains to ferment at 43°C; wherein, the walnut pulp is obtained by wet grinding of peeled walnut kernels through a colloid mill; the fermentation The base material includes walnut pulp, auxiliary materials, glucose and sucrose, which are prepared by mixing; the auxiliary materials include gellan gum and water, which are obtained by mixing and stirring for 22 minutes at 55 ° C; the mass ratio of refrigerant and water in the auxiliary materials is 1:60; the concentration of walnut kernels in the fermented base material is 15wt%; the concentration of disaccharides in the fermented base material is 2.1wt%; the concentration of monosaccharides in the fermented base material is 3.5wt%; the fermentation The concentration of the a...

Embodiment 2

[0047] The present embodiment provides a kind of fermentation method of pure walnut fermented milk, described method comprises:

[0048] Enzymolytic fermentation: mix the pretreated fermentation base material and compound flavor protease, and then add fermentation strains to ferment at 41°C; wherein, the walnut pulp is obtained by wet grinding of peeled walnut kernels through a colloid mill; the fermentation The base material includes walnut pulp, auxiliary materials, fructose and maltose, which are prepared by mixing; the auxiliary materials include sodium tripolyphosphate and water, which are obtained by mixing and stirring at 61°C for 20 minutes; the quality of sodium tripolyphosphate and water in the auxiliary materials The ratio is 1:65; the concentration of walnut kernels in the fermented base material is 10wt%; the concentration of disaccharides in the fermented base material is 2.6wt%; the concentration of monosaccharides in the fermented base material is 5wt%; The con...

Embodiment 3

[0051] The present embodiment provides a kind of fermentation method of pure walnut fermented milk, described method comprises:

[0052] Enzymolysis fermentation: mix the pretreated fermentation base material with neutral protease and compound flavor protease, and then add bacterial agents to ferment at 40°C; wherein, the walnut pulp is obtained by wet grinding of peeled walnut kernels through a colloid mill; The fermentation base material includes walnut pulp, auxiliary materials, fructose and sucrose, which are prepared by mixing; the auxiliary materials include sodium carboxymethylcellulose and water, which are obtained by mixing and stirring for 25 minutes at 65°C; the carboxymethyl The mass ratio of sodium cellulose and water is 1:70; the concentration of walnut kernels in the fermented base material is 20wt%; the concentration of disaccharides in the fermented base material is 3wt%; the concentration of monosaccharides in the fermented base material 2wt%; the concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com