Method for setting parallel incomplete disassembly line for disassembling waste products

A product, obsolete technology, applied in the field of setting parallel incomplete dismantling lines, which can solve problems such as poor convergence, long search time, and poor solution quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

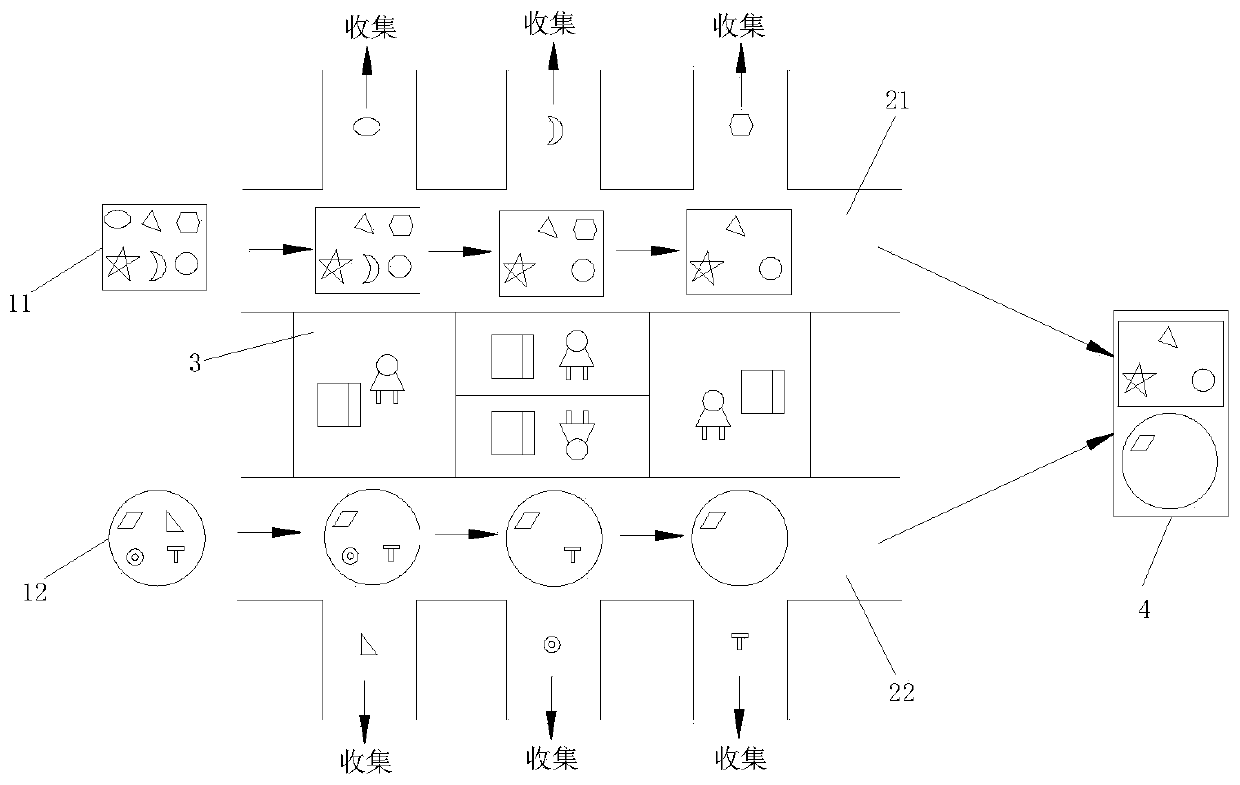

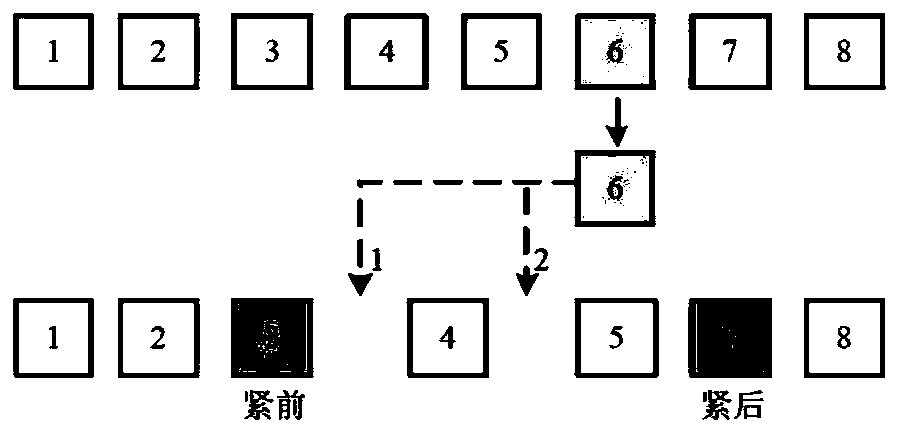

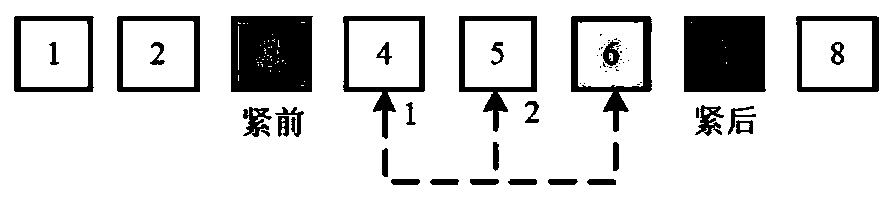

Method used

Image

Examples

Embodiment 1

[0104] The information obtained from the survey of a company’s waste refrigerators and TV sets is as follows:

[0105] 1. The data information of the disassembly task of the waste refrigerator is shown in Table 1, and the data information of the disassembly task of the waste TV is shown in Table 2, where: in the hazard attribute, "0" means no harm, and "1" means yes Hazard; in the demand attribute, "0" means no demand, "1" means there is demand; disassembly resource means dismantling tools corresponding to each disassembly task, "1" means screwdriver, "2" means scissors, and "3" means word Change the knife, "4" means pliers, and "5" means fixed heavy equipment tools such as cutting machines and punching machines.

[0106] Table 1

[0107]

[0108]

[0109] Table 2

[0110]

[0111] 2. The priority relationship diagram of disassembly tasks for used refrigerators is as follows Figure 5 As shown, the priority order of disassembly tasks for used TV sets is as follows Image 6 Shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com