On-line production line management system

A management system and production line technology, applied in the general control system, control/regulation system, comprehensive factory control, etc., can solve problems such as false positives or false positives of operating status monitoring, loss of OEE and production efficiency, unfamiliarity with equipment operations, etc. , to achieve the effect of improving labor productivity, improving product quality and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

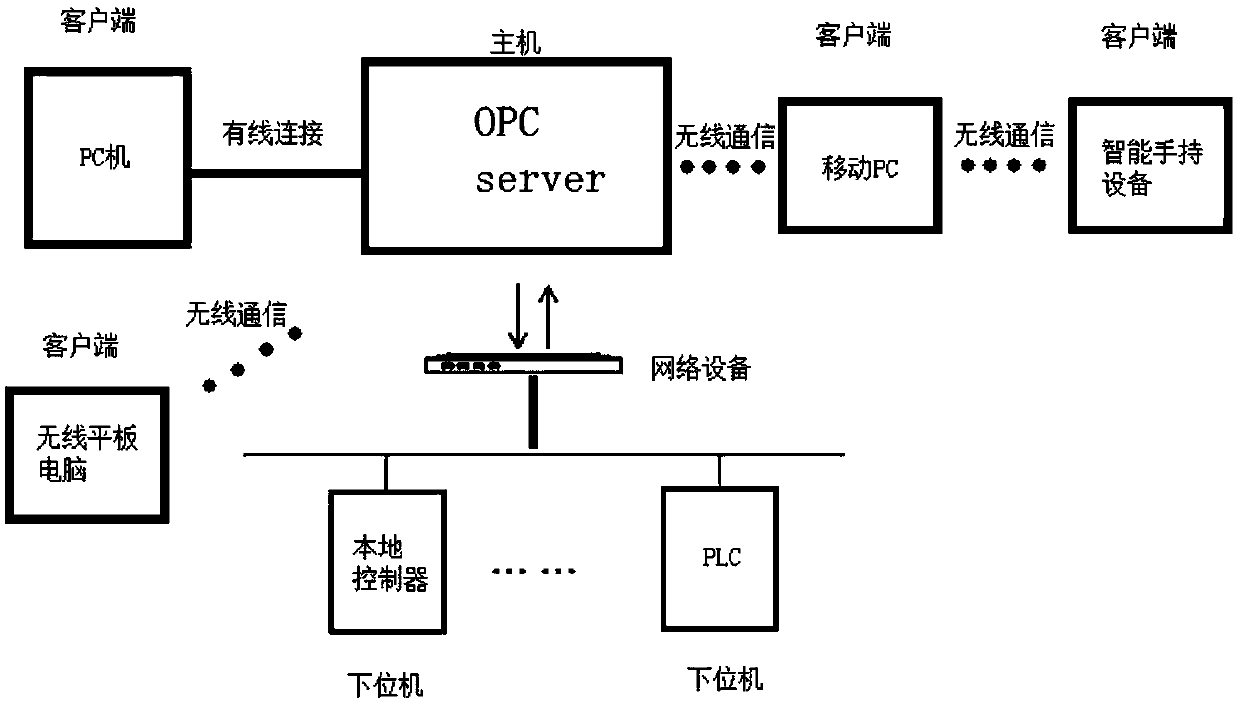

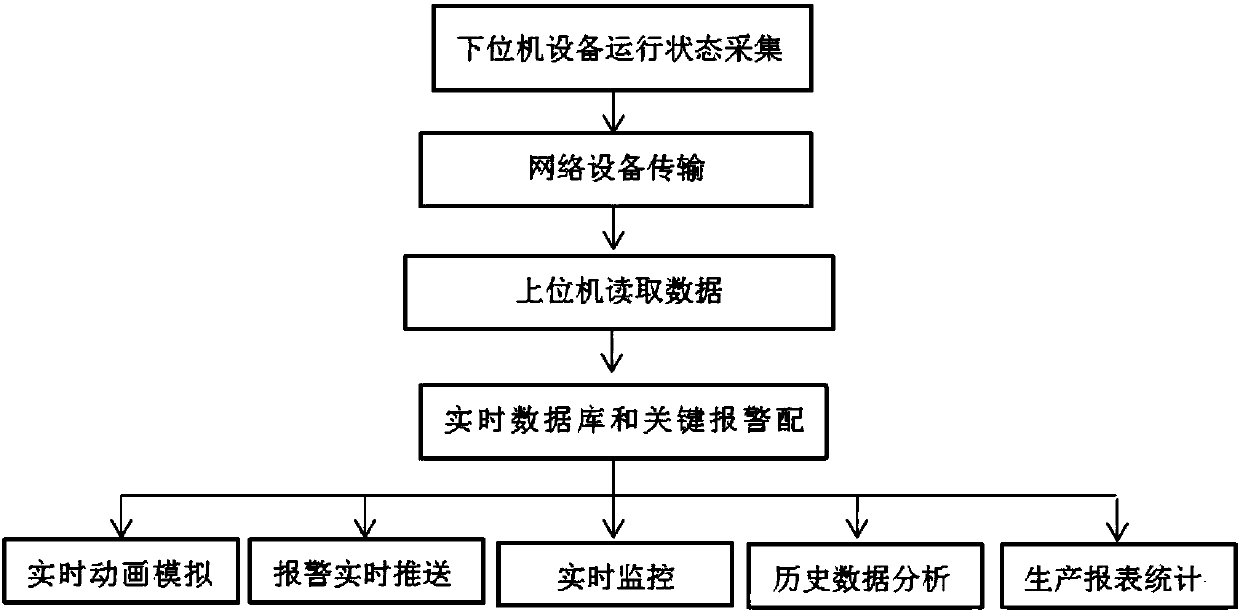

[0027] Such as figure 1 As shown, an embodiment of the production line online management system provided by the present invention includes: a lower computer, a network device and an upper computer;

[0028] The lower computer, usually a PLC or a local controller, realizes the local logic control of the production line equipment, is responsible for the collection, conversion, transmission and processing of the running status of each component of the production line equipment, controls the production line equipment to complete the local process, and controls the production line equipment to realize local functions, that is, the Complete the established production functions and tasks of the equipment.

[0029] The network equipment connects the upper computer and the lower computer, which is a network architecture based on the OPC communication protocol, and is responsible for the real-time signal transmission between the upper computer and the lower computer;

[0030] The numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com