A kind of activated carbon and its preparation method and application

A technology of activated carbon and activator, applied in chemical instruments and methods, electrolytic capacitors, capacitors, etc., can solve the problems of poor electrochemical performance and low specific surface area of activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of gac, comprises the following steps:

[0021] Combine pod shells with H 3 PO 4 After the solutions are mixed, a hydrothermal reaction is carried out to obtain coke, and the temperature of the hydrothermal reaction is 170-180°C;

[0022] Activating the coke by mixing it with an activator to obtain an activated product, the activator being KOH or NaOH;

[0023] The activated product was washed successively with hydrochloric acid and water to obtain the activated carbon.

[0024] The present invention combines bean pod shell with H 3 PO 4 After the solutions are mixed, a hydrothermal reaction is carried out to obtain coke, and the temperature of the hydrothermal reaction is 170-180°C. In the present invention, the H 3 PO 4 The mass fraction of the solution is preferably 5 to 20%, more preferably 10 to 15%, and the pod shell and H 3 PO 4 The dosage ratio of the solution is preferably 1.5-2g:50mL.

[0025] In th...

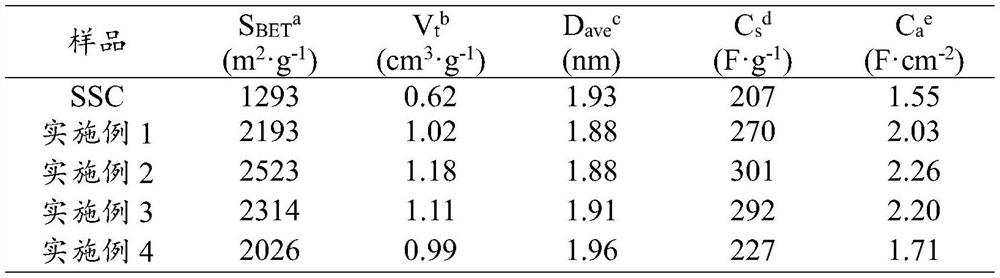

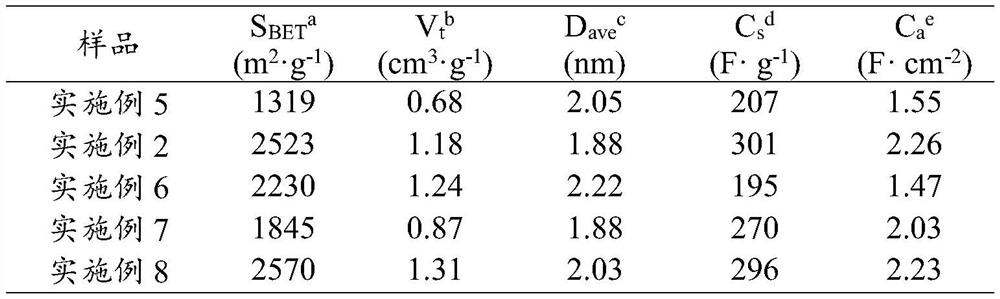

Embodiment 1

[0041] 2g bean pod shell and 50mL mass fraction are 5wt.% H 3 PO 4 The solution was mixed and ultrasonicated for 30 minutes, placed in a hydrothermal kettle at 180°C for 12 hours, and the obtained solid product was washed with ethanol and deionized water and then dried to obtain coke.

[0042] Mix and grind the coke and KOH, the mass ratio of KOH to coke is 3:1, keep it at the activation temperature of 700°C for 2 hours, and clean it to obtain a specific surface area of 2193m 2 g -1 Activated carbon with high specific surface area.

[0043] The obtained activated carbon is prepared into a supercapacitor electrode sheet. The preparation process is to weigh the activated carbon, acetylene black and PTFE with a mass ratio of 85:10:5 and place them in an agate grinder for grinding, and then use a desktop tablet press (6MPa) The sample is pressed on the nickel foam (collector) to make a disc electrode with a diameter of 13mm. The mass of activated carbon is about 10mg. The ele...

Embodiment 2

[0045] Same as Example 1, the only difference is that H 3 PO 4 The mass fraction of the solution is 10%.

[0046] The specific surface area of the activated carbon that present embodiment makes is 2523m 2 g -1 , the specific capacitance is 301F·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com