Aluminum alloy casting die with ridge surfaces

A technology of casting molds and aluminum alloys, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of labor load, aluminum water cannot fill the molding cavity, and reduce production efficiency, so as to reduce costs and save casting raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

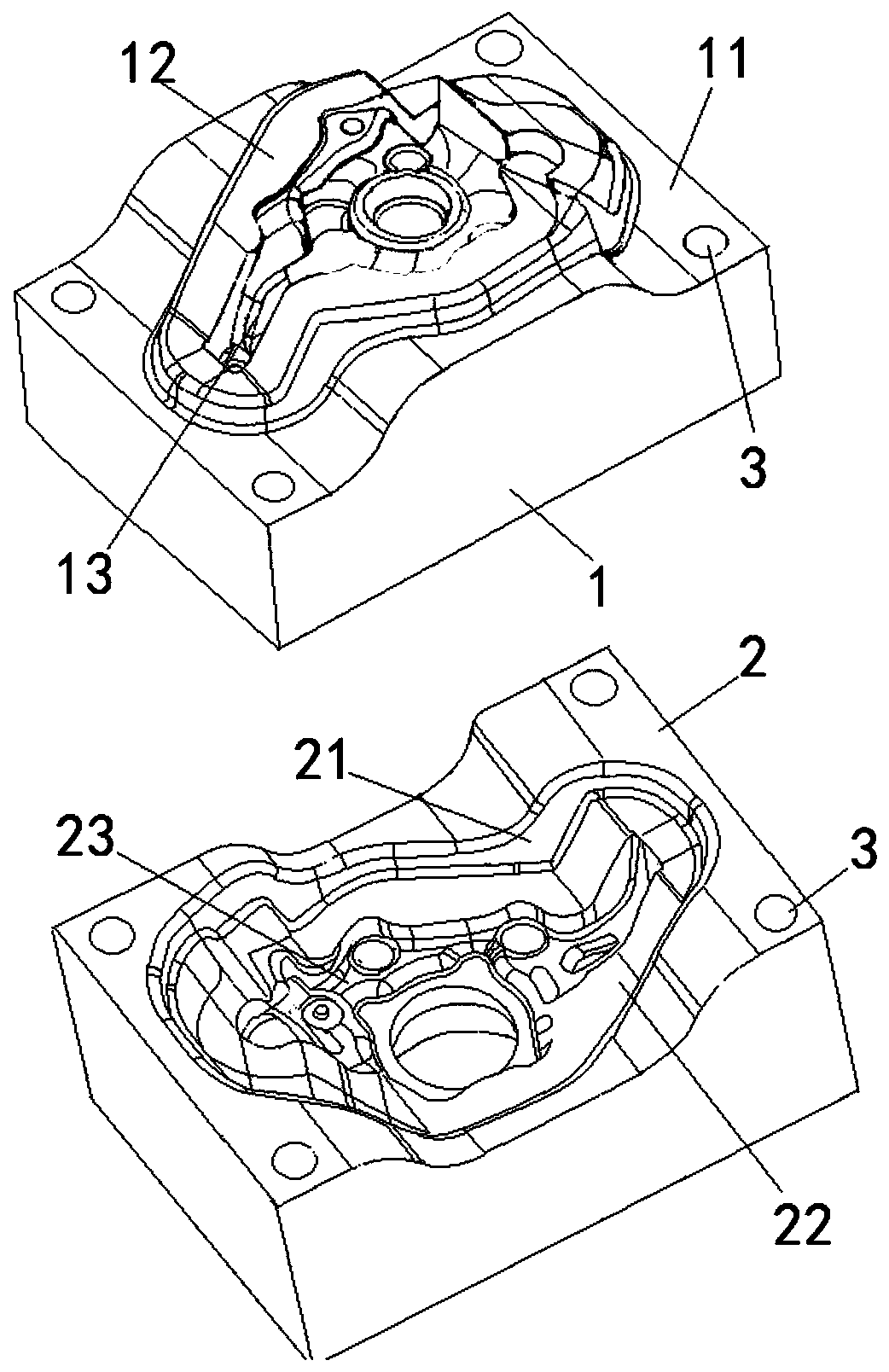

[0011] Such as figure 1 As shown, an aluminum alloy casting mold with a rim joint surface includes a male mold 1 and a female mold 2. The upper end surface of the male mold 1 is provided with a male rim joint surface 11, and the center of the upper end surface of the male rim joint surface 11 is There is a rim joint platform 12, and a male mold forming cavity 13 is provided at the center of the upper end surface of the kangaroo platform 12, and a female rim joint surface 21 is provided on the upper end surface of the female mold 2. There is a cam groove 22, and the center of the upper end surface of the cam groove 22 is provided with a female mold forming cavity 23, and the four corners of the male mold 1 and the female mold 2 are provided with fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com