Cooling ring bracket

A cooling ring and bearing ring technology, applied in the direction of pipe support, bearing cooling, rigid support of bearing components, etc., can solve the problems of cooling ring failure, loosening, fasteners, etc., and achieve the possibility of hose damage sex-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the figures, like numerals refer to like objects throughout. Objects in the drawings are not necessarily drawn to scale.

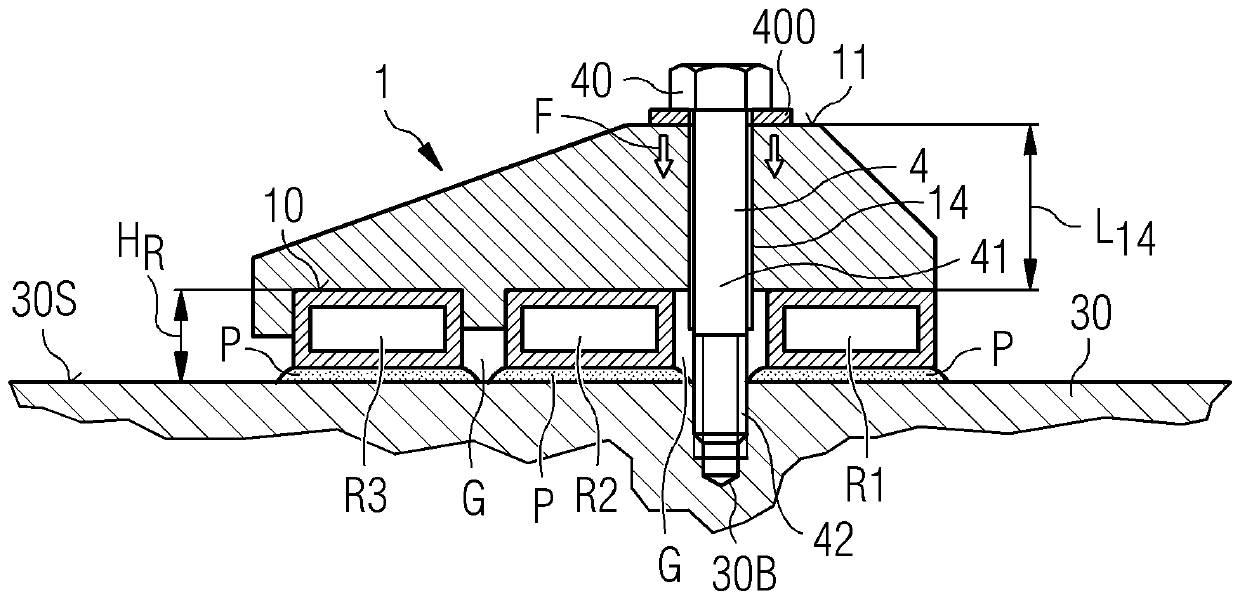

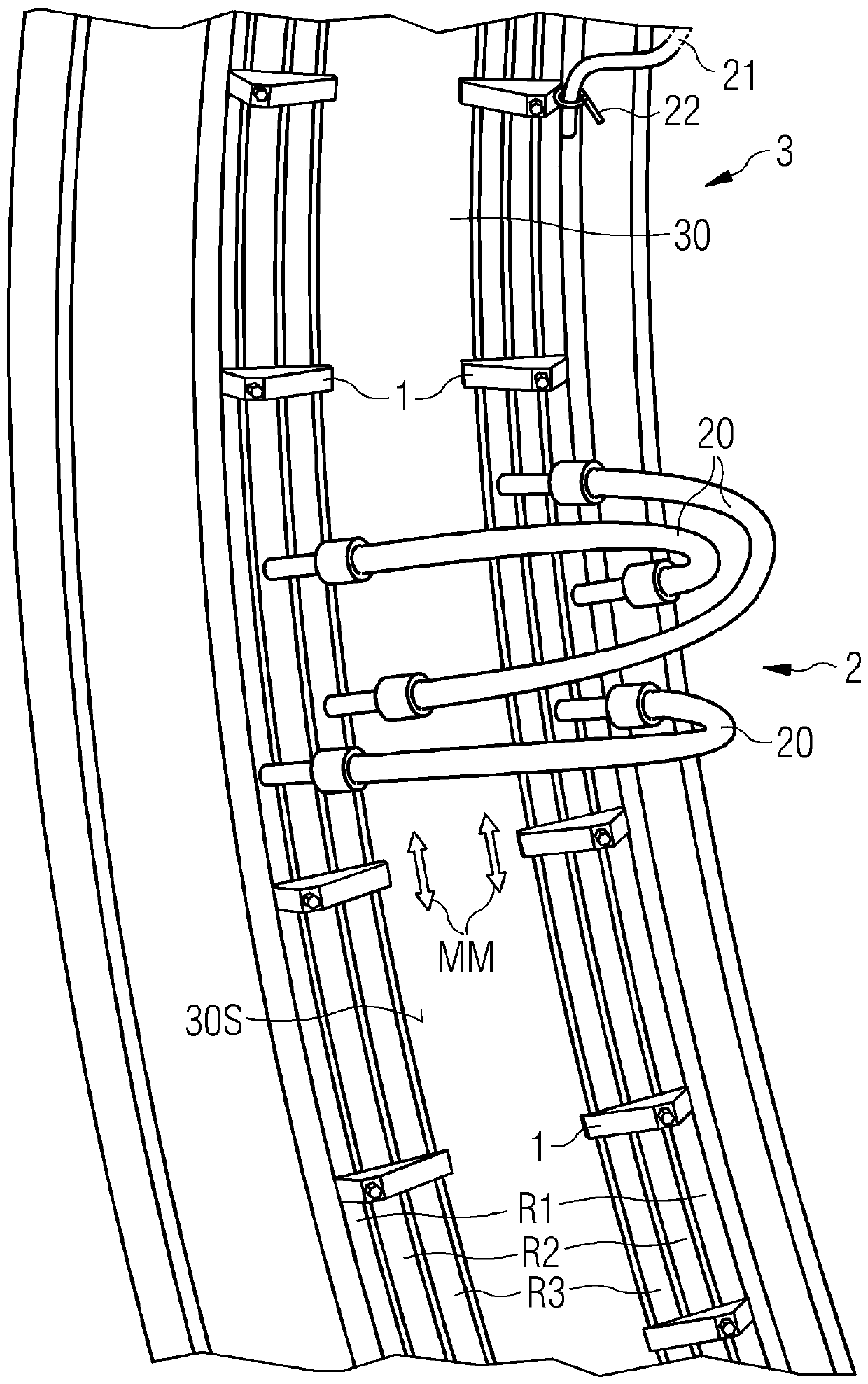

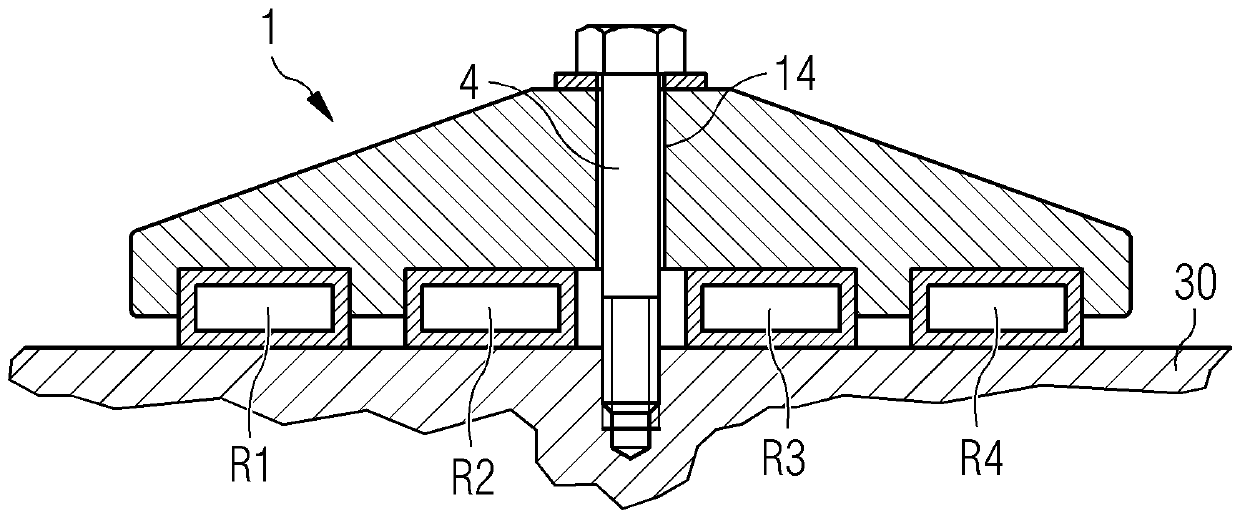

[0035] figure 1 An embodiment of a stent 1 of the invention is shown. The support 1 is formed in one piece, eg by injection molding, and is realized extending across three parallel cooling rings R1 , R2 , R3 . The main body of the bracket 1 is roughly in the shape of an acute trapezoid, and its highest point is located above the gap G between two adjacent cooling rings R1, R2. The stand 1 extends substantially from the base level 10 to the upper level 11 and its shape is defined by inclined sides extending from the base level 10 to the upper level 11 . The stent is made from a highly resilient material that also exhibits a favorable degree of elasticity and resiliency, allowing it to assume its original shape after being compressed. A suitable choice of material may be a high performance engineering polymer such as polyoxymethylene (POM-C) du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com