Method for inspecting casing leakage in coal-bed gas well

A coalbed methane well and casing technology, which is applied in construction and other fields, can solve the problems of inconvenient casing inspection and achieve the effects of reducing cost investment, reducing weight and water pressure, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

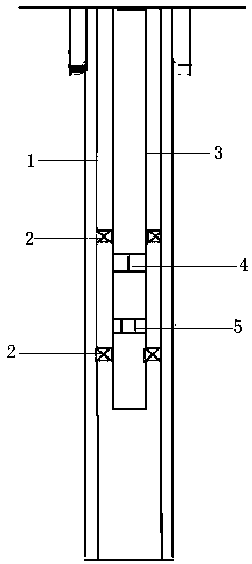

[0022] refer to figure 1 , a method for checking casing leakage in a coalbed methane well, comprising the following steps:

[0023] S1: Seal the bottom of the tool string with the bottom ball, then put the tool string into the production casing, and pressurize from the top opening of the tool string. When the tool string is pressurized at 0.8-1.0MPa, two sets of packers are set. When pressurizing, the pressure is monitored through the pressure gauge. The pressure gauge is connected to the controller, and the controller is connected to the pressurizer. The model of the packer is K344. The controller can preset the pressure value. When the pressure gauge detects If the pressure value is not within the preset range, the controller controls the pressurizer to adjust the pressure. When pressurizing, the temperature sensor detects the temperature data in the bushing and records the detected data. The temperature sensor and The display screen is connected, and the display screen is ...

Embodiment 2

[0030] refer to figure 1 , a method for checking casing leakage in a coalbed methane well, comprising the following steps:

[0031] S1: Seal the bottom of the tool string with the bottom ball, then put the tool string into the production casing, and pressurize from the top opening of the tool string. When the tool string is pressurized at 0.8-1.0MPa, two sets of packers are set. When pressurizing, the pressure is monitored through the pressure gauge. The pressure gauge is connected to the controller, and the controller is connected to the pressurizer. The model of the packer is K344. The controller can preset the pressure value. When the pressure gauge detects If the pressure value is not within the preset range, the controller controls the pressurizer to adjust the pressure. When pressurizing, the temperature sensor detects the temperature data in the bushing and records the detected data. The temperature sensor and The display screen is connected, and the display screen is ...

Embodiment 3

[0038] refer to figure 1 , a method for checking casing leakage in a coalbed methane well, comprising the following steps:

[0039] S1: Seal the bottom of the tool string with the bottom ball, then put the tool string into the production casing, and pressurize from the top opening of the tool string. When the tool string is pressurized at 0.8-1.0MPa, two sets of packers are set. When pressurizing, the pressure is monitored through the pressure gauge. The pressure gauge is connected to the controller, and the controller is connected to the pressurizer. The model of the packer is K344. The controller can preset the pressure value. When the pressure gauge detects If the pressure value is not within the preset range, the controller controls the pressurizer to adjust the pressure. When pressurizing, the temperature sensor detects the temperature data in the bushing and records the detected data. The temperature sensor and The display screen is connected, and the display screen is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com