A division method of prefabricated basic modules of ring main unit and its installation and connection method

A basic module and module connection technology, which is applied in the direction of basic structure engineering, architecture, building structure, etc., can solve the problems of large construction area, large construction risk, long construction period, etc., and achieve small construction site area, On-site management and control workload is reduced and the construction period is shortened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

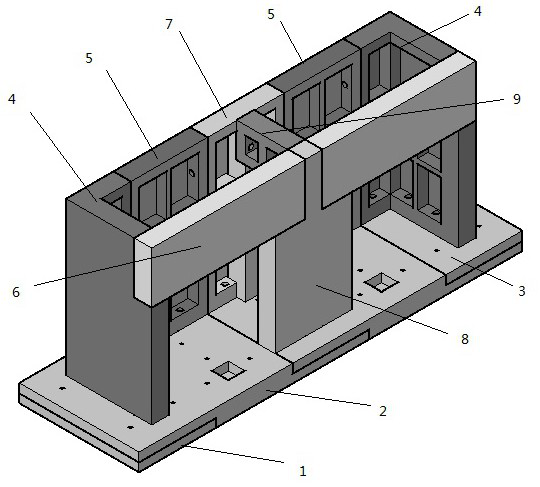

[0058] Embodiment: first prefabricate each module No. 1 board module, No. 2 board module, No. 3 board module, No. 4 wall module, No. 5 wall module, No. 6 beam module, No. 7 wall module, No. 8 wall module, and No. 9 beam Modules, transport each module to the construction site, prepare accessories such as mortar, screw, bolt, grouting material, and then start assembling.

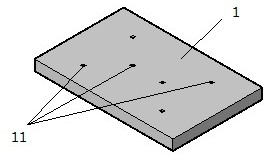

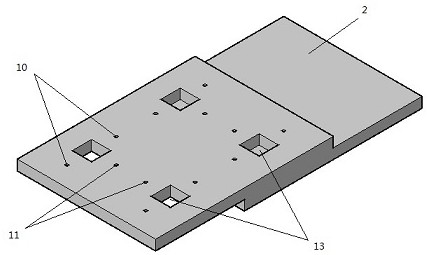

[0059] 1) Hoist the No. 1 plate module, No. 2 plate module and No. 3 plate module, screw in the screw to splice, level the foundation, and lift the spliced plate module after simple tamping;

[0060] 2) Pour mortar into the variable cross-section cylindrical reserved hole where the bottom plate module and No. The mortar is self-compacting, and the screw is screwed into the reserved bolt hole at the bottom to connect with the pre-embedded threaded sleeve on the bottom plate module;

[0061] 3) Pour mortar into the variable cross-section cylindrical reserved hole at the junction of the base plate module and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com