Steel grid ring type wind power tower base ring facility and construction method

A steel grid and foundation ring technology is applied in the construction field of steel grid ring wind power tower foundation ring facilities, which can solve the problems of not considering the force form of the wind turbine foundation, and achieve improved bonding effect, simple construction, and high efficiency. The effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

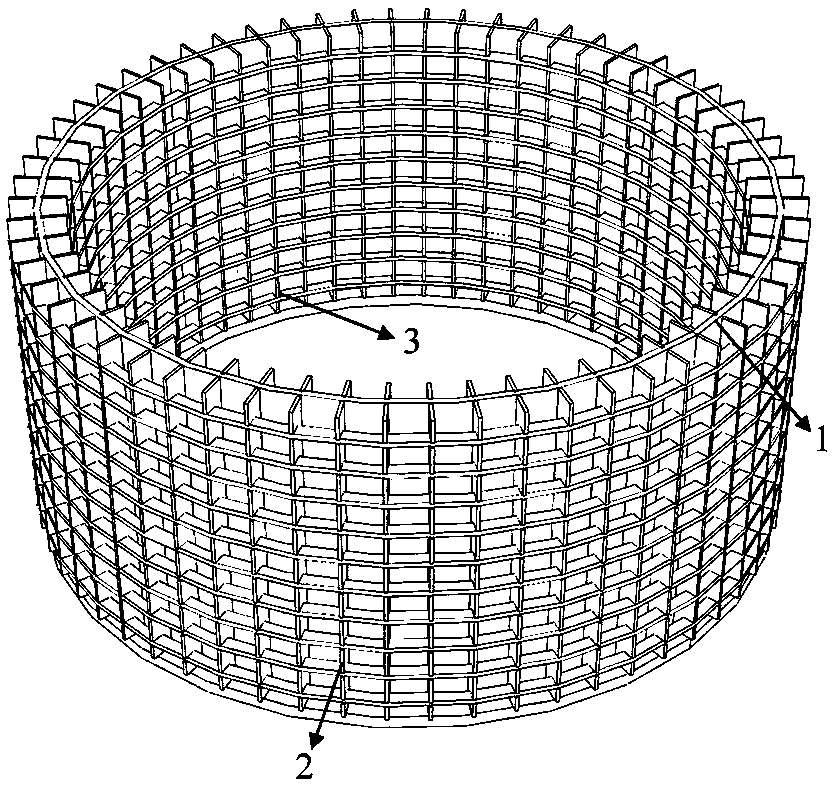

[0031] like figure 1 As shown, the steel grid ring type wind power tower base ring facility of the present invention includes a fan base ring 1 with a flange plate, an outer steel grid ring 2 and an inner steel grid ring 3 .

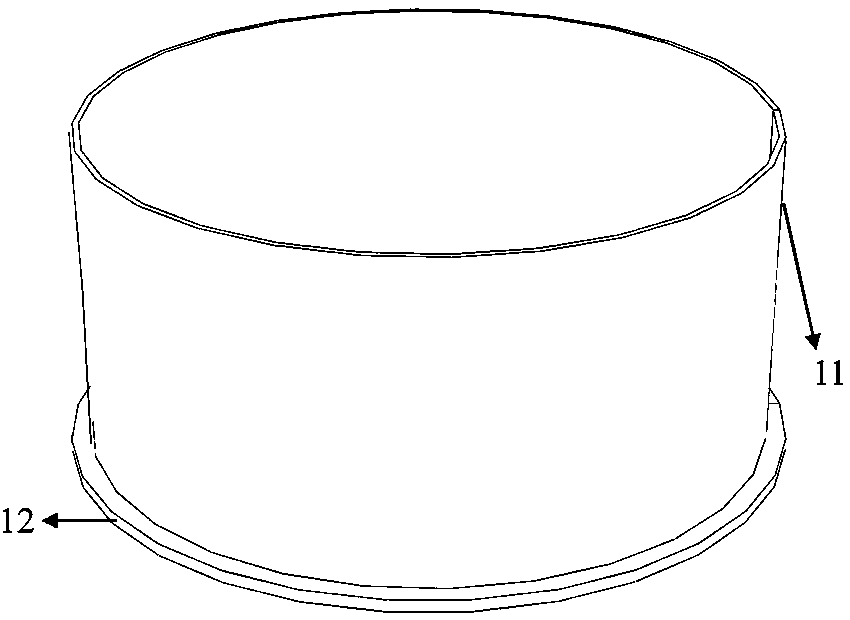

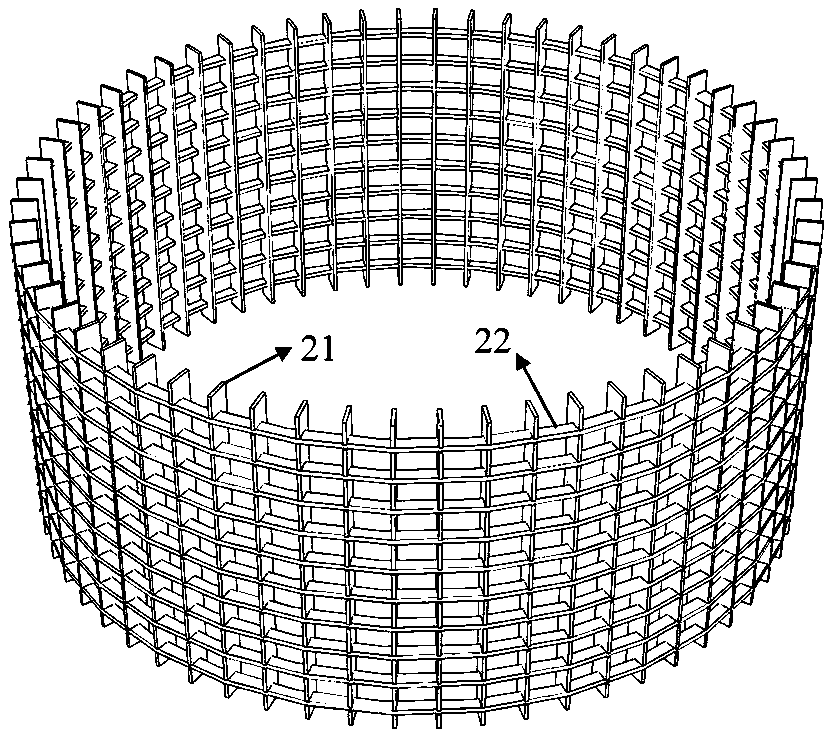

[0032] like figure 2 , Figure 5 , Image 6 As shown, the basic ring 1 of the fan with flange plate includes the basic ring 11 of the fan and the flange plate 12, and the basic ring 11 of the fan is welded to the upper end of the flange plate 12; image 3 , 7 As shown in ~9, the outer steel grating ring 2 includes the vertical steel grating strip group 21 of the outer ring, the horizontal steel grating plate group 22 of the outer ring, and the horizontal steel grating plate group 22 of the outer ring is sequentially inserted into the outer ring according to the direction of the outer ring. Circle the reserved rectangular holes of the vertical steel grating bar group 21, and weld and seal the reserved rectangular holes; Figure 4 , 10 As shown in ~...

Embodiment 2

[0047] like Figure 14As shown, the difference between this embodiment and Embodiment 1 is that: the base ring of the fan is a double-layer steel pipe; the reserved holes of the vertical steel grid strip group of the outer ring are reserved oblong holes; The reserved holes facing the steel grid bar group are reserved oblong holes; the outer ring horizontal steel grid plate group is the outer ring ribbed steel mesh; the inner ring horizontal steel grid plate group is the inner ring strip Ribbed steel mesh. The rest of the structures and connections in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0049] like Figure 15 As shown, the difference between this embodiment and Embodiment 1 is that: the foundation ring of the fan is a hollow interlayer concrete filled steel pipe; the reserved holes of the vertical steel grid strip group of the outer ring are reserved oblong holes; the inner ring The reserved holes of the vertical steel grid bar group are reserved oblong holes; the outer ring horizontal steel grid plate group is the outer ring cold-rolled twisted steel mesh; the inner ring horizontal steel grid plate group is the outer Ring cold rolled twisted steel mesh. The rest of the structures and connections in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com