A method for improving the quality of sintered ore of vanadium-titanium magnetite concentrate

A vanadium-titanium magnetite concentrate and sintering technology, which is applied in the field of iron and steel metallurgy, can solve the problems of increasing the high temperature holding time in the sintering process, decreasing the drum index of sintering ore, and reducing the vertical sintering speed, so as to reduce the vertical sintering speed and prolong the sintering process. Effect of time, quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

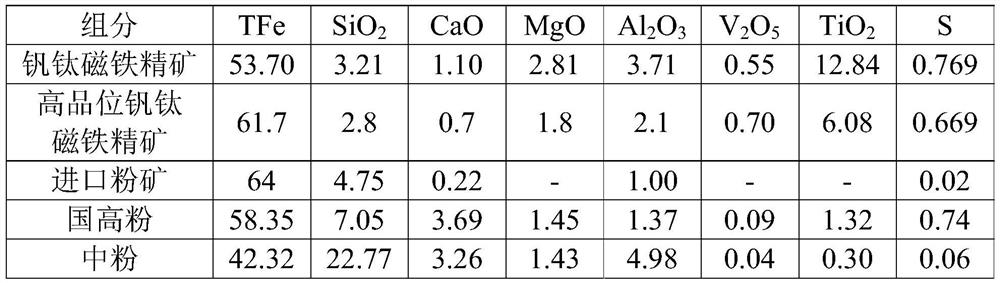

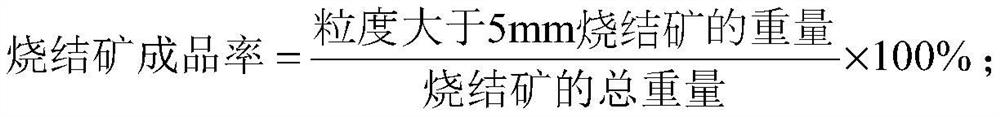

Embodiment 1

[0052] (1) dry mix sintered raw materials and return ore for 4min, and obtain dry material after mixing, and the consumption of described return ore is 30 parts by weight; (2) add water to the dry material obtained in step (1) and carry out a mixing successively for 4min and Secondary mixing for 4 minutes, controlling the moisture content of the obtained sintered mixture to be 7.2% by weight; (3) distributing the obtained sintered mixture in step (2), controlling the thickness of the material layer at 650 mm, igniting and sintering, wherein the ignition time 2min, the ignition negative pressure is 6kPa, and the sintering negative pressure is 12kPa, wherein, the sintering raw material contains 36% by weight of vanadium-titanium magnetite concentrate, 20% by weight of high-grade vanadium-titanium magnetite concentrate, and 14% by weight of Guogao Powder, 10% by weight of imported fine ore, 5% by weight of medium powder, 5.5% by weight of limestone, 5.3% by weight of active ash an...

Embodiment 2

[0056] (1) dry mix sintered raw materials and return ore for 5 minutes, and obtain dry material after mixing, and the consumption of described return ore is 15 parts by weight; (2) add water to the dry material obtained in step (1) and carry out a mixing successively for 4 minutes and Secondary mixing for 3.5min, controlling the moisture content of the obtained sintered mixture to be 7.0% by weight; (3) distributing the obtained sintered mixture in step (2), controlling the thickness of the material layer at 680mm, igniting and sintering, wherein the ignition The time is 2 minutes, the ignition negative pressure is 6.5kPa, and the sintering negative pressure is 13kPa, wherein, the sintering raw material contains 36% by weight of vanadium-titanium magnetite concentrate, 20% by weight of high-grade vanadium-titanium magnetite concentrate, 14% by weight of Guogao powder, 10% by weight of imported fine ore, 5% by weight of medium powder, 5.7% by weight of limestone, 5.1% by weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com