Oil well cement for ultrahigh-temperature deep well and preparation method and application thereof

A cementing cement and ultra-high temperature technology, which is applied in the field of oil drilling, can solve the problems of long-term strength decline and achieve the effects of prolonging the life of oil wells, good thermal stability, and ensuring long-term sealing integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

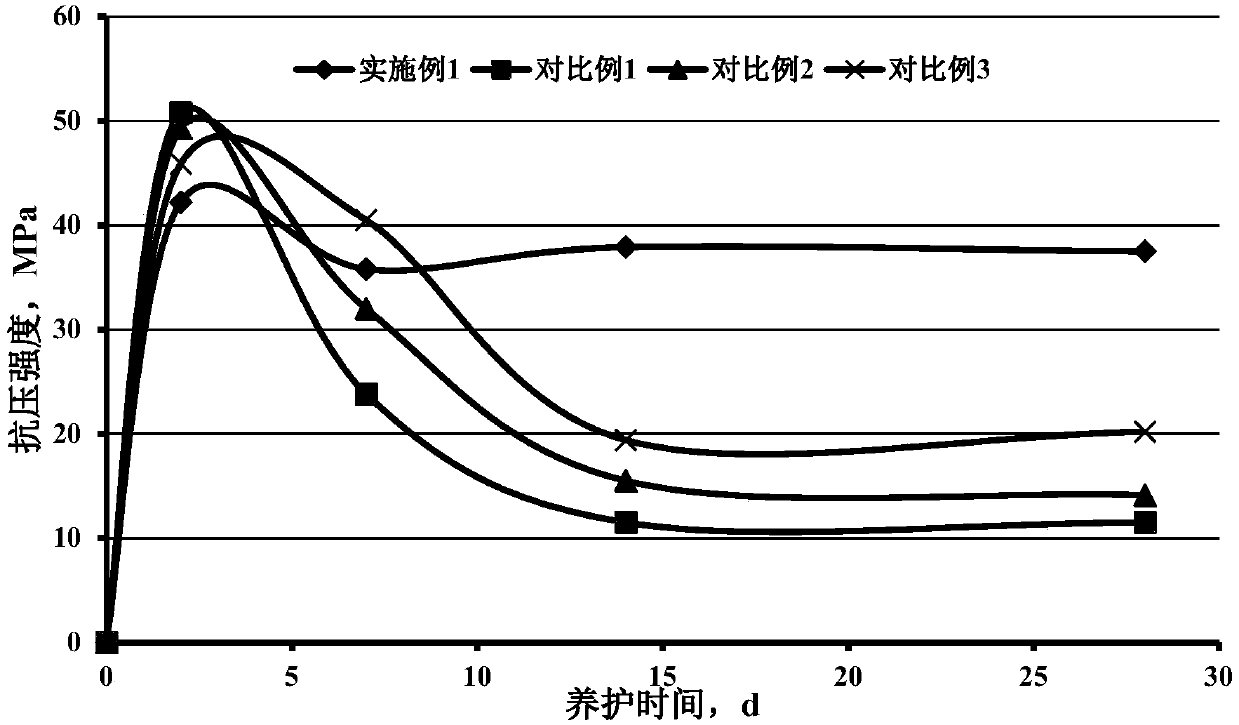

Examples

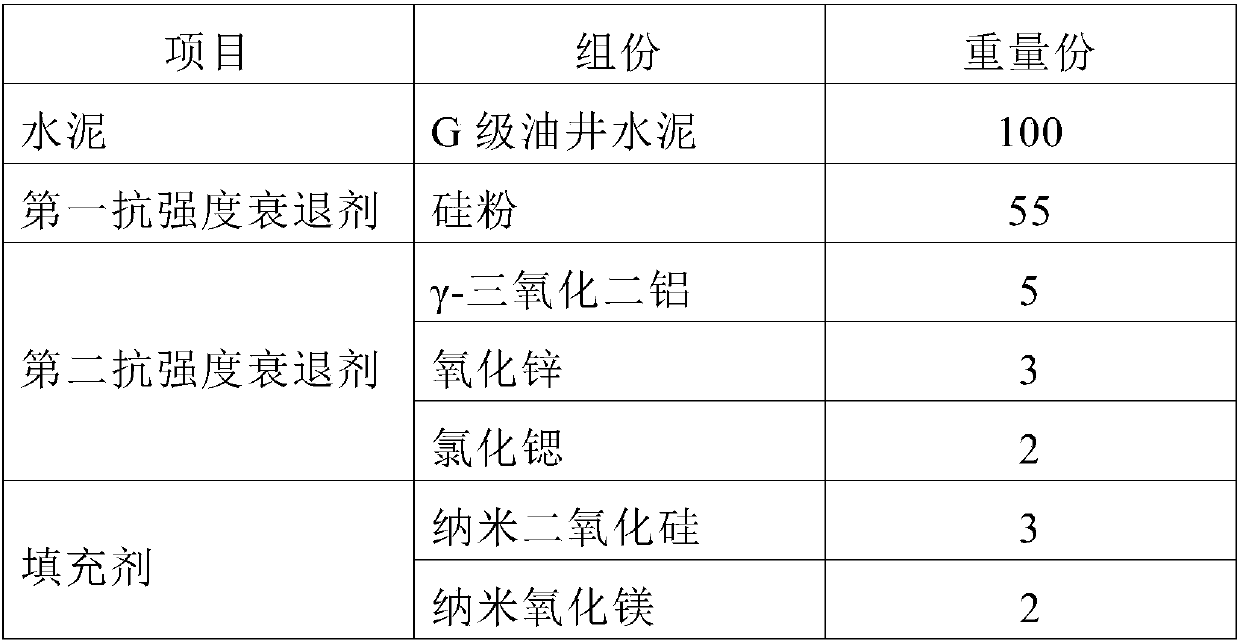

Embodiment 1

[0051] This example provides a cementing cement for ultra-high temperature deep wells, and its components and parts by weight are shown in Table 1.

[0052] Table 1 The formula of cementing cement used in ultra-high temperature deep wells

[0053]

[0054] According to the above ratio, add the above components into the ash mixing equipment, and fully mix them evenly to obtain the cement for ultra-high temperature deep wells.

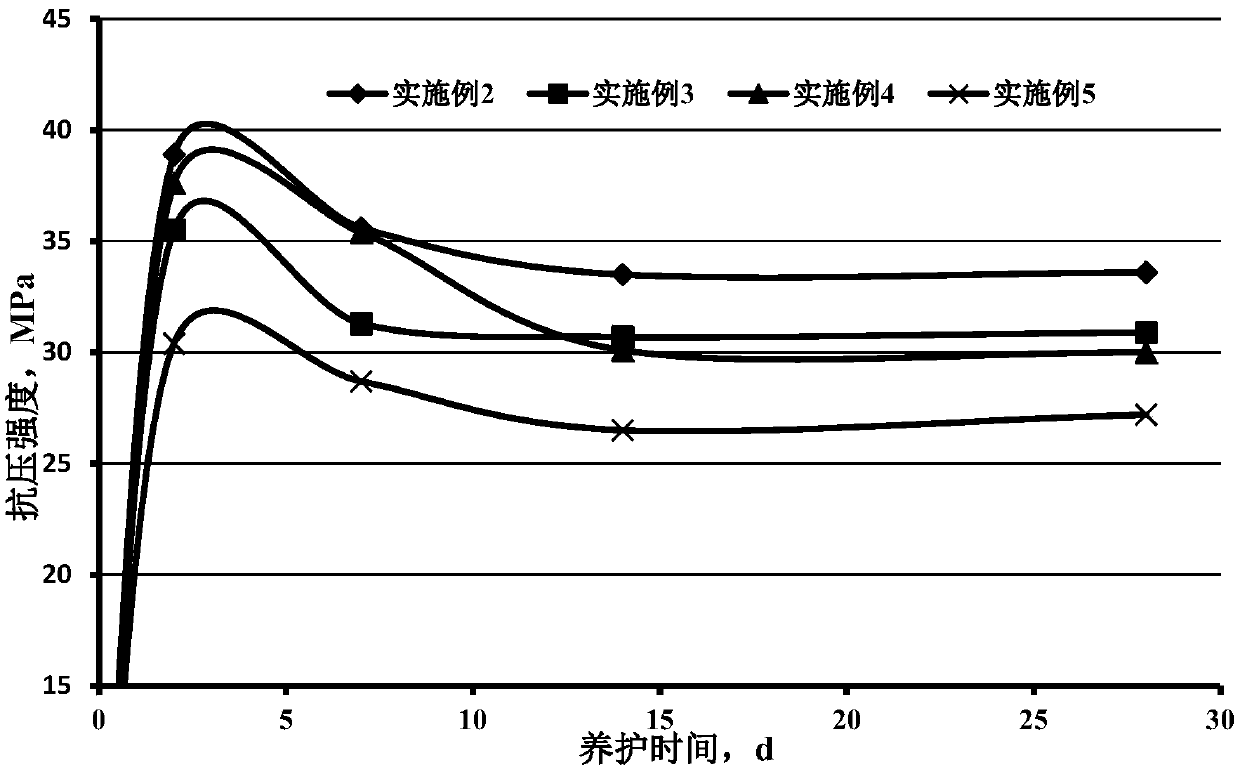

Embodiment 2

[0056] This example provides a cementing cement for ultra-high temperature deep wells, and its components and parts by weight are shown in Table 2.

[0057] Table 2 The formulation of cementing cement used in ultra-high temperature deep wells

[0058]

[0059] According to the above ratio, add each component into the ash mixing equipment, and fully mix evenly to obtain the cement for ultra-high temperature deep well.

Embodiment 3

[0061] This example provides a cementing cement for ultra-high temperature deep wells, and its components and parts by weight are shown in Table 3.

[0062] Table 3 The formula of cementing cement used in ultra-high temperature deep wells

[0063]

[0064] According to the above ratio, add each component into the ash mixing equipment, and fully mix evenly to obtain the cement for ultra-high temperature deep well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com