Assembly method of internal part of large adsorber

An assembly method and absorber technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problem of long length of the right lifting beam, and achieve the effects of reducing site space requirements, saving materials, and reducing span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

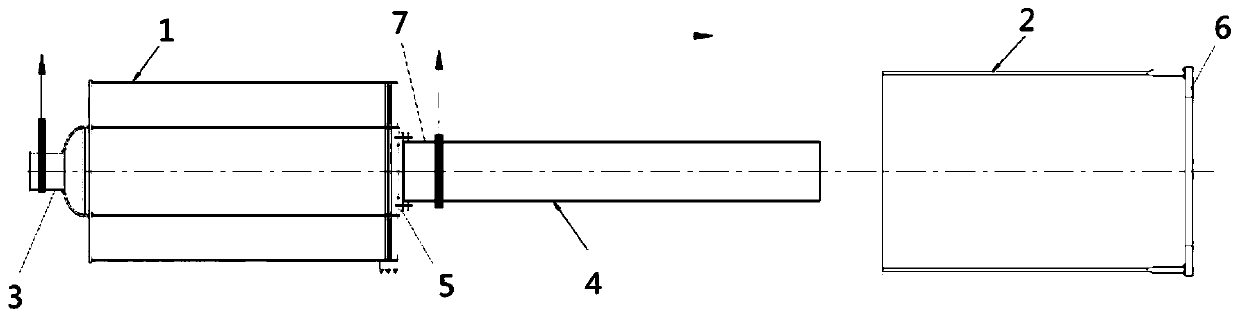

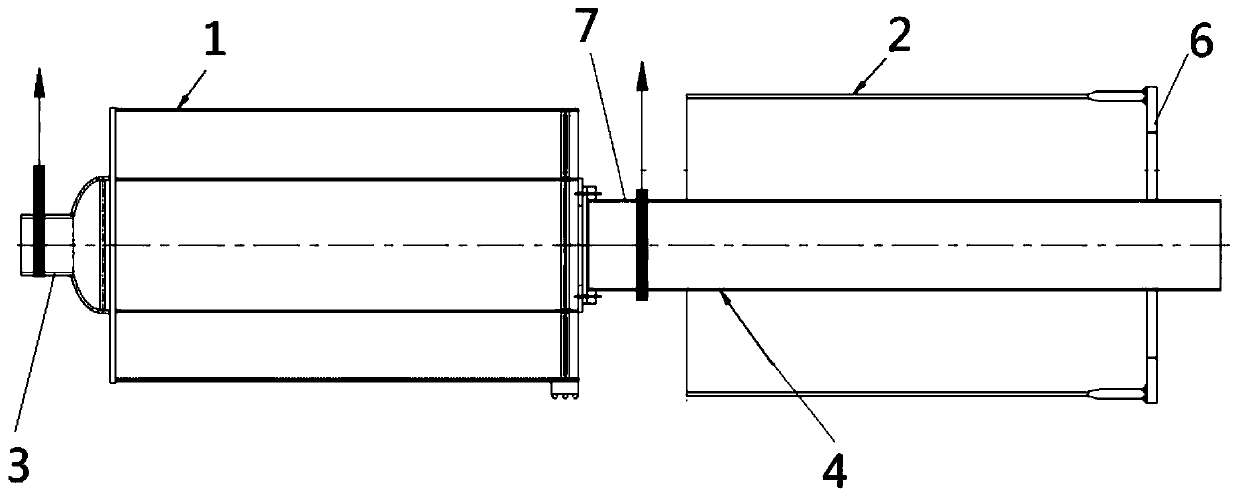

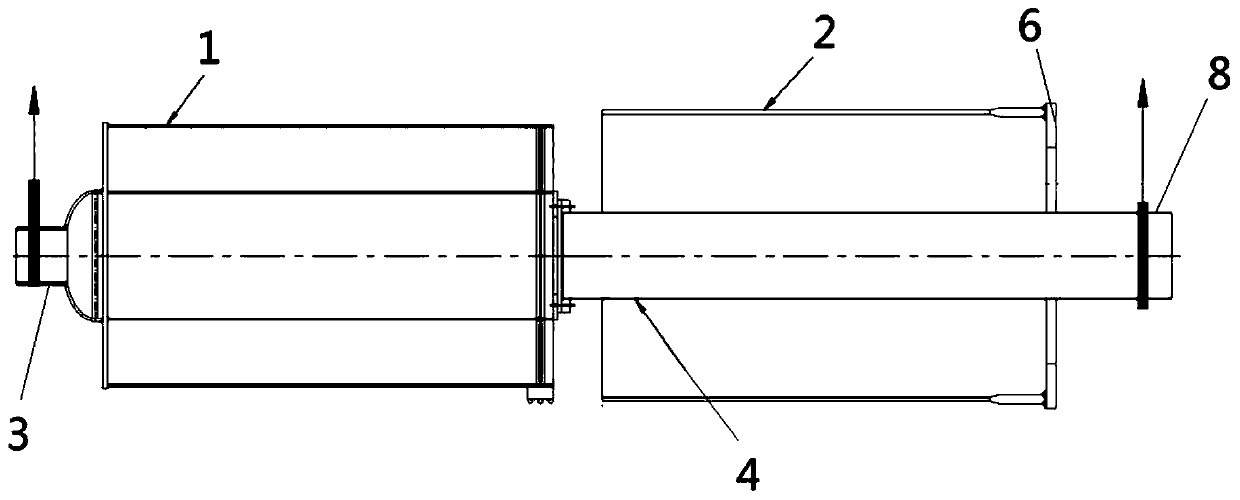

[0036] see Figure 5-8 , a large-scale adsorber internals assembly method, comprising the following steps:

[0037] Place the screen cylinder 10 and the cylinder body 20 respectively, and align the screen cylinder 10 with the cylinder body 20; the length of the screen cylinder after lying down is 14 meters, and the height (diameter of the cylinder cylinder) is 7-8 meters. The length is 14 meters, and the height (cylinder diameter) is 6.5 meters to 7.5 meters.

[0038] The lower inner wall of the cylinder is detachably connected with an axial guide rail for guiding and load bearing.

[0039] Make the left and right lifting beams, the length of the left lifting beam 30 is about 1 meter, the left lifting beam 30 is detachably (bolted) connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com