Bearing press suitable for different dies

A press and bearing technology, applied in the field of bearing presses, can solve the problem of inability to quickly call different types of tooling, and achieve the effect of improving work flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

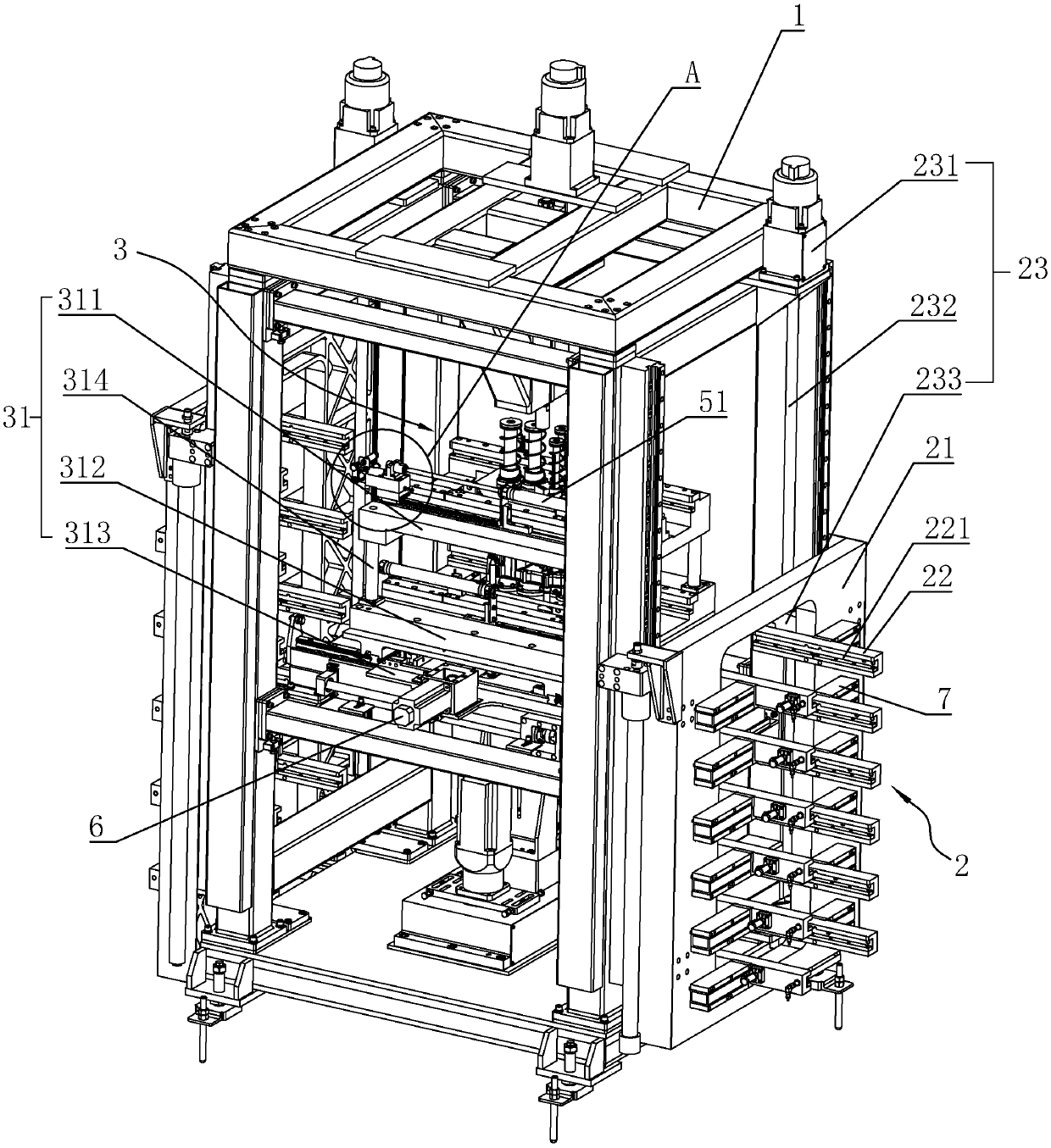

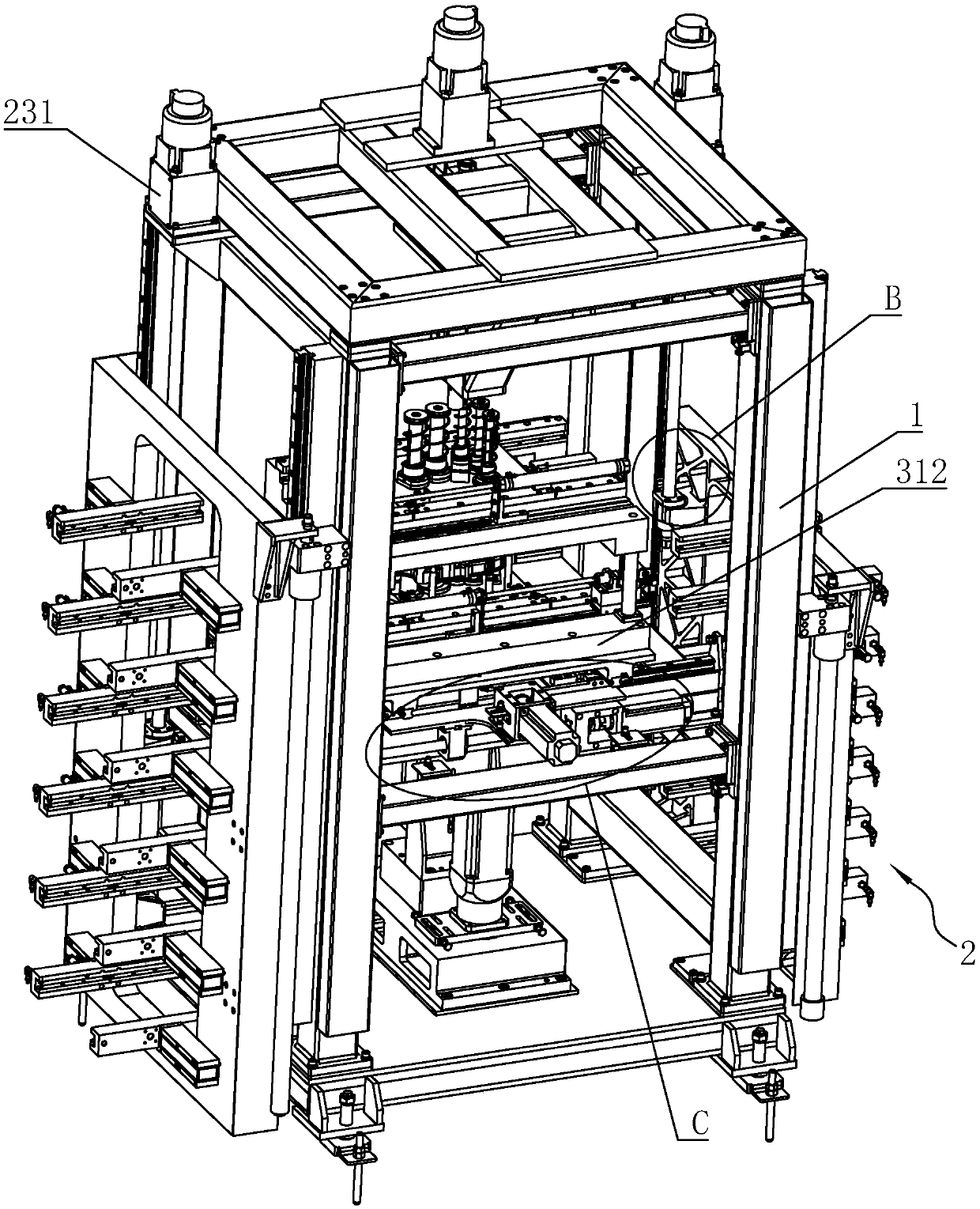

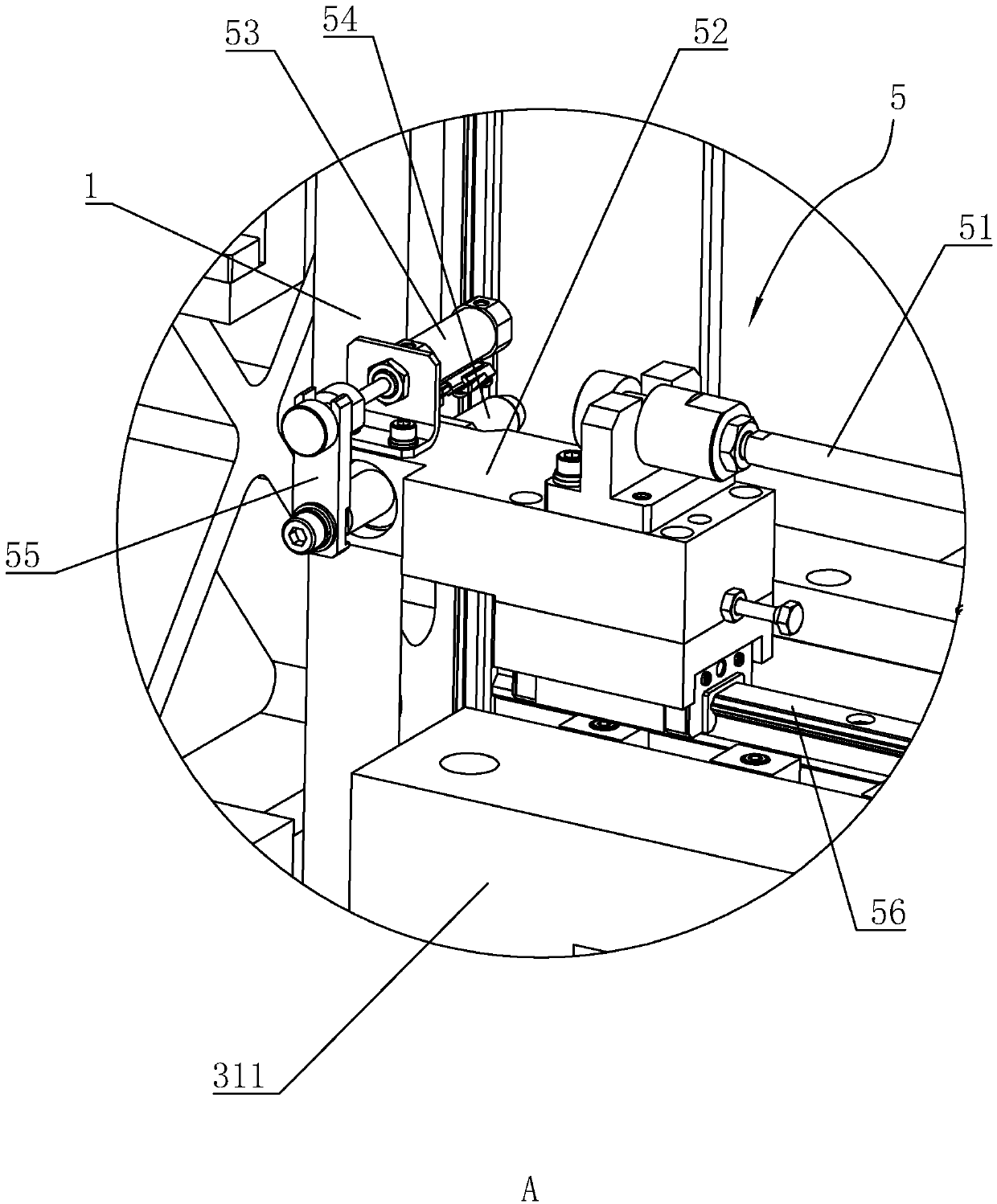

[0030] Embodiment: A kind of bearing pressing machine applicable to different moulds, such as figure 1 , figure 2 and Figure 4 , including a frame 1 and a tooling conveying mechanism 2 arranged on both sides of the frame 1 along the length direction, the conveying mechanism 2 includes a carrier frame 21, and the side of the frame 1 facing the carrier frame 21 is fixedly provided with a vertical slide rail 4, carrying The frame 21 is provided with a guide block 41 matched with the vertical slide rail 4 , so that the carrier frame 21 can slide vertically on both sides of the frame 1 . The frame 1 is provided with a drive member 23 for driving the carrier frame 21 to move vertically. The drive member 23 includes a first drive motor 231 fixedly connected to the end of the frame 1 away from the ground. On the output end of the first drive motor 231 A threaded mandrel 232 is fixed coaxially, and a fixed block 233 is fixedly provided on the side of the carrier frame 21 towards th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com