Outboard machine for large-elevation full-rotation ship

A technology of full rotation and large elevation angle, applied in the field of outboard motors, it can solve the problems of small rotation angle, inconvenient installation, inspection, and maintenance, etc., and achieve the effect of wide application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

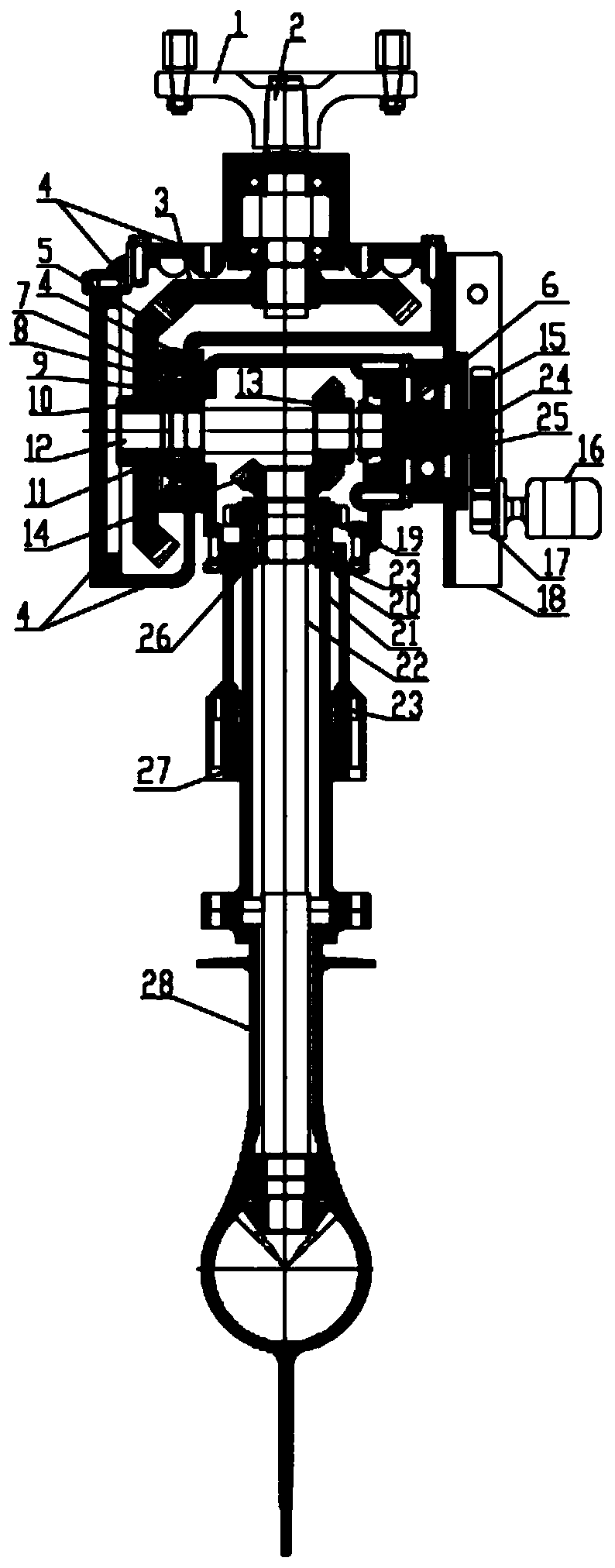

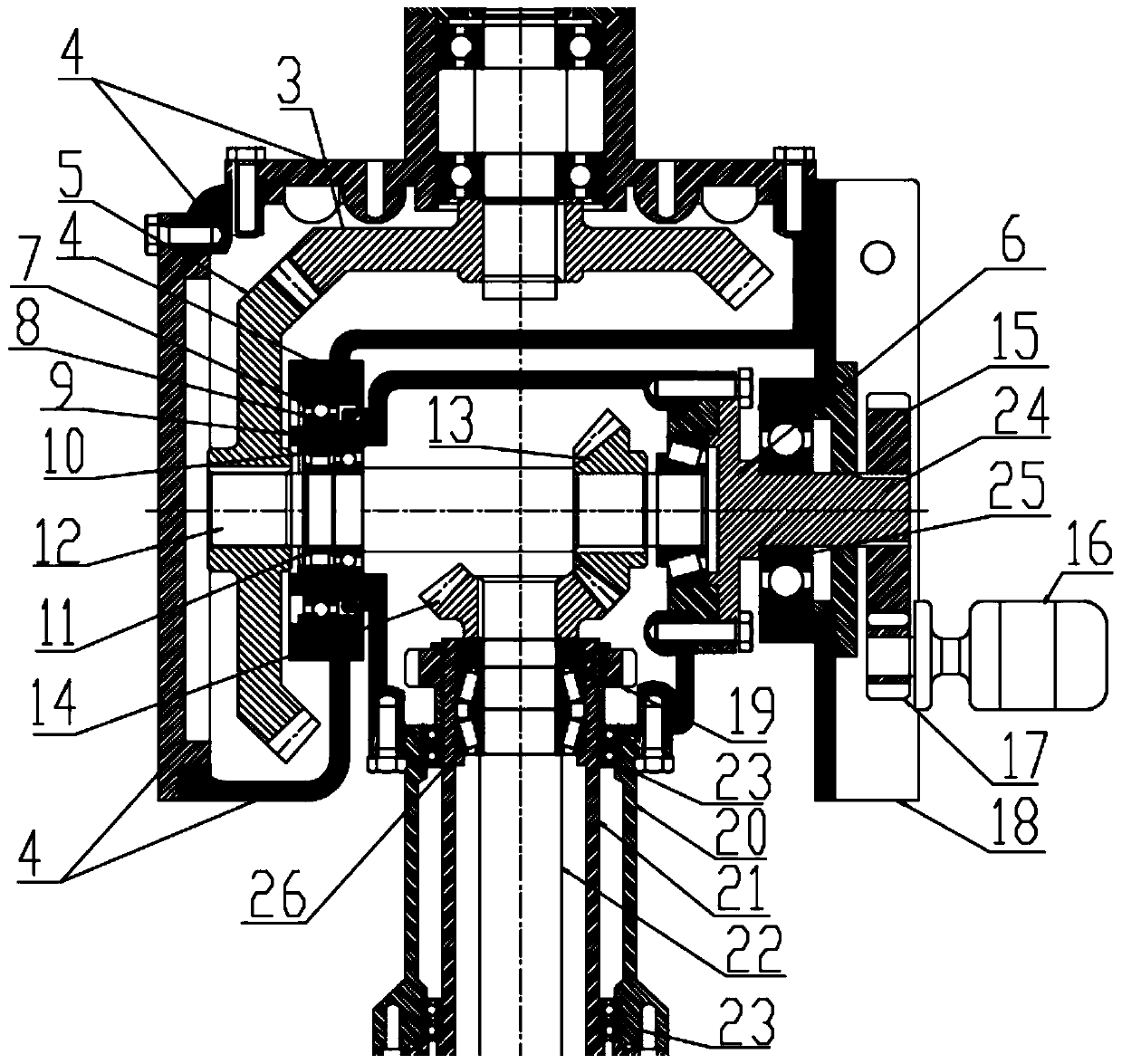

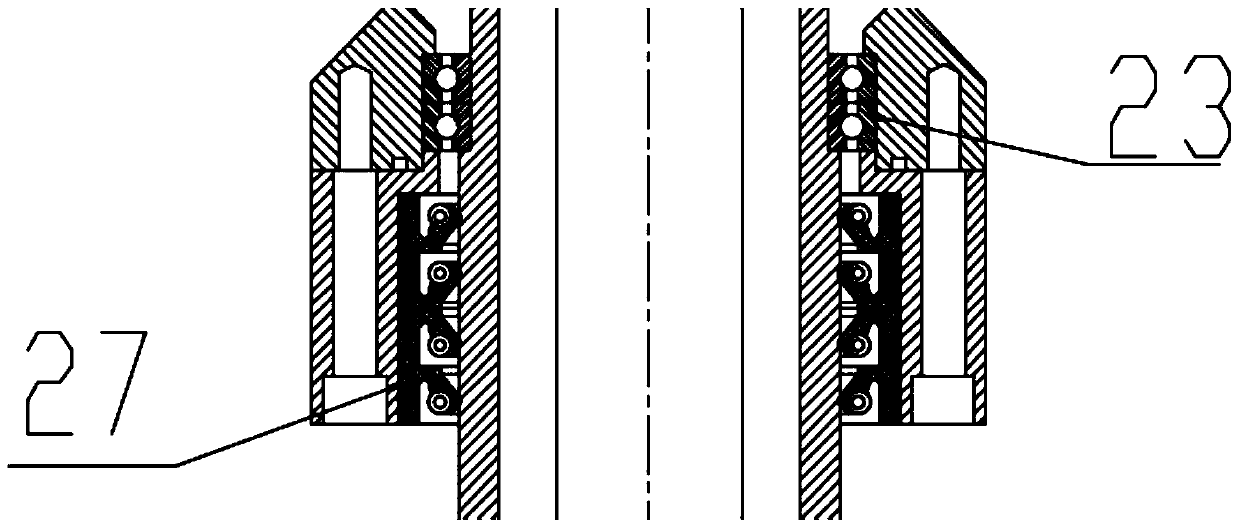

[0028] Such as Figure 1-6 As shown, a large-angle full-rotation marine outboard motor includes an upper box body 9, a transmission box body 4 and a lower box body 28, and the transmission box body 4 is surrounded by an upper end cover, an L-shaped shell and side walls to form an L cavity body, the upper box body 9 is located at the shelter of the L-shaped cavity body, and one end of the upper box body 9 is connected with the end cover shaft by bolts, and the end cover shaft includes the end cover 6 and the lifting transmission Shaft 24, the end cover 6 and the lifting transmission shaft 24 are integrally formed by casting, the other end of the upper box 9 is connected to the first rotary bearing 8 on the transmission box 4, and the lifting transmission shaft 24 is lifted The transmission shaft support bearing 25 is connected on the upper case bracket 18, and the transmission case 4 is connected with the upper case 9 through the upper case input shaft 12, and the upper case in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com