A sideways turning method of a large flat frame type workpiece

A frame-type, workpiece-based technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of broken rope accidents, waste, time-consuming, etc., and achieve the effect of avoiding time and cost waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0030] A method for overturning a large flat frame type workpiece, comprising the following steps:

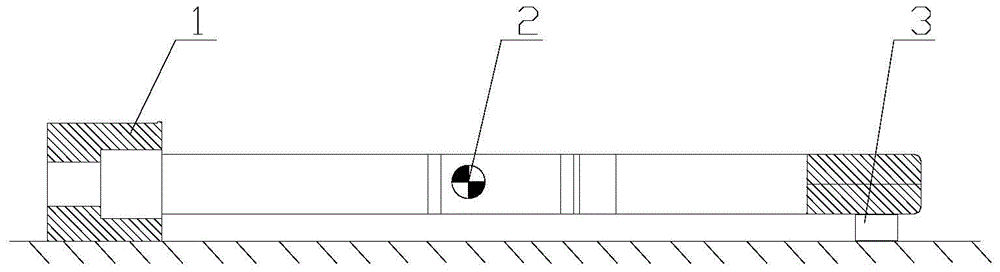

[0031] 1) Place the workpiece 1 horizontally, pad the lower part with the support block 3 to make the workpiece 1 horizontal, use a crane to lift it, and use the forged steel double-sided hook head 8 for the hook head;

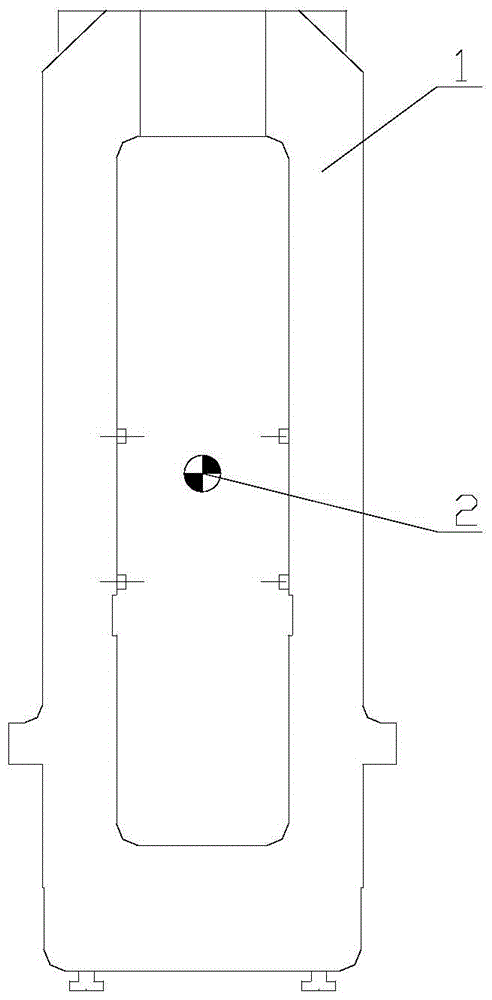

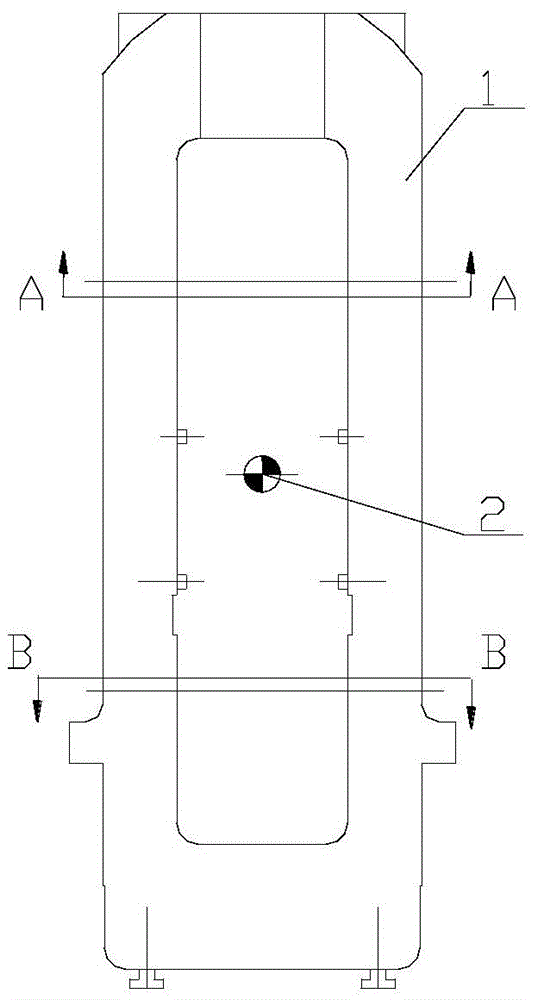

[0032] 2) Set two lifting points along the length direction, the lifting points are symmetrically set on both sides of the center of gravity 2 of the workpiece, and the distance between them is 2 / 7 to 1 / 3 of the total length of the workpiece 1;

[0033] 3) Use four steel wire ropes 4, 5, 6, and 7 of equal length for hoisting. The total load is the weight of the workpiece 1 multiplied by the safety factor. The load value of each steel wire rope is calculated as 1 / 3 to 1 / 4 of the total load, and Based on this, determine the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com