Drill bit for high-TG plate targeting hole machining

A hole processing and drilling technology, which is used in the field of high TG sheet target hole processing drills, can solve the problems of large hole wall burrs, wear, hole straightness, and poor roundness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

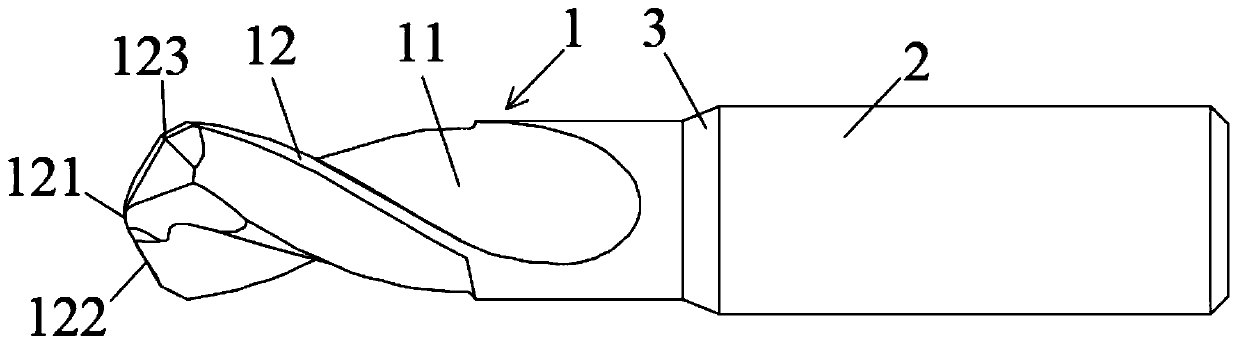

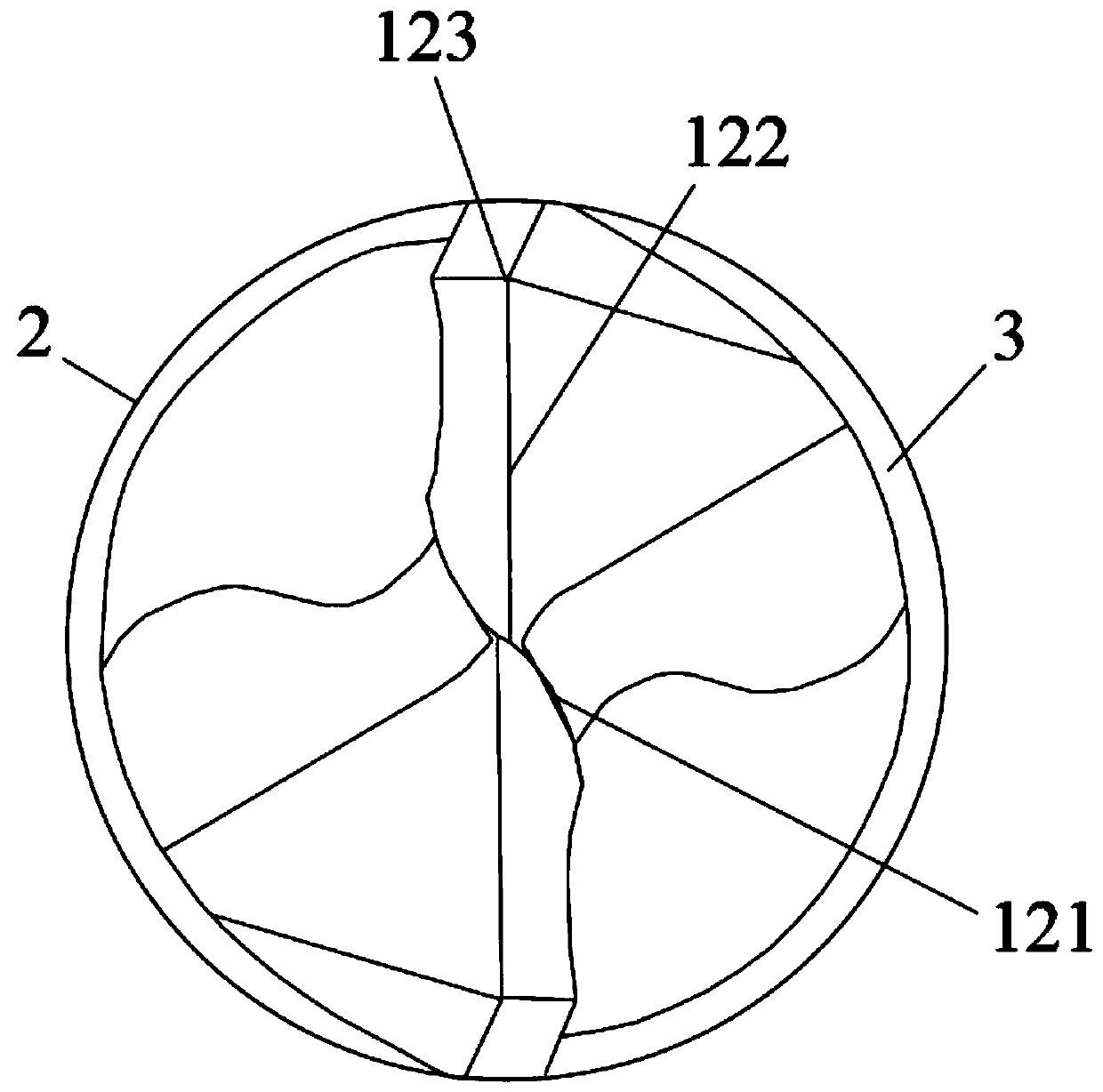

[0026] Such as Figure 1-2 As shown, a drill bit for high TG sheet metal target hole processing, including a drill body 1 and an extended shank 2, the drill body 1 and the extended shank 2 are connected through a transition cone 3, and the drill body 1 is provided with a knife groove 11 and a cutting edge 12 , the sipe 11 is set adjacent to the blade 12, and the end of the blade 12 is provided with a chisel edge 121, a low-edge drill point 122 and a knife-point protection structure 123, and the chisel edge 121, the low-edge drill point 122, and the knife-point protection structure 123 are sequentially connect. The drill point has a grinding chisel edge 121, which is sharp and the plate is not easily deformed; because the sharp points on both sides of the top corner are protected by the tool tip, which is not limited to a straight line or arc shape, the tool tip is resistant to chipping and wear; the side edge The mode of grinding the back angle or retaining the cylindrical ed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com