Three-degree-of-freedom parallel driving joint

A degree of freedom, parallel technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of space size, structural quality and load quality, and can not achieve parallel structure layout, so as to reduce inertial load, reduce The effect of quality and installation location concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

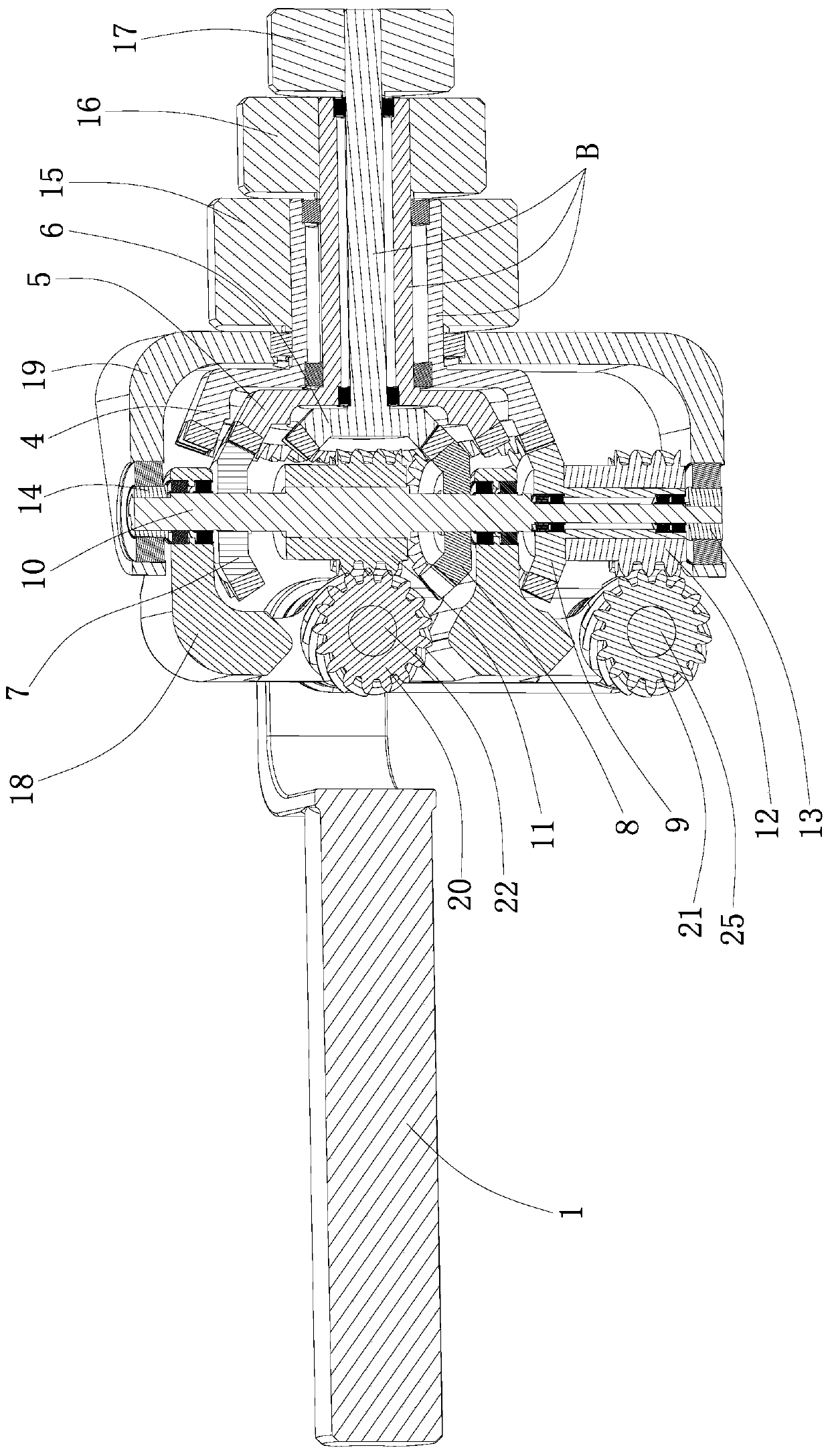

[0018] see Figure 1-Figure 3 As shown, a three-degree-of-freedom parallel drive joint is characterized in that: it comprises a joint motion link frame 1, a three-degree-of-freedom motion mechanism 2 and a motor group 3;

[0019] The three-degree-of-freedom motion mechanism 2 includes a connecting rod fixing frame 18, a torsion fixing frame 19 and a motion transmission assembly 2A;

[0020] The articulation link frame 1 is rotatably connected with the connecting rod fixing frame 18, the connecting rod fixing frame 18 and the torsion fixing frame 19 are rotatably connected, and the motion transmission component is installed on the connecting rod fixing frame 18 and the torsion fixing frame 19, and the torsion fixing frame 19 is connected with the torsion fixing frame 19. The output end of the motor group 3 is connected and can rotate relative to the motor group 3 , and the motion transmission component is driven by the motor group 3 to move to realize the torsion, pitch and yaw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com