A heald frame with full carbon fiber composite structure

A composite material and carbon fiber technology, applied in healds, textiles, papermaking, textiles, etc., can solve problems such as frame fracture, fatigue deformation of heald frame structure, yarn breakage, etc., to reduce inertial load, improve overall strength, and suppress The effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

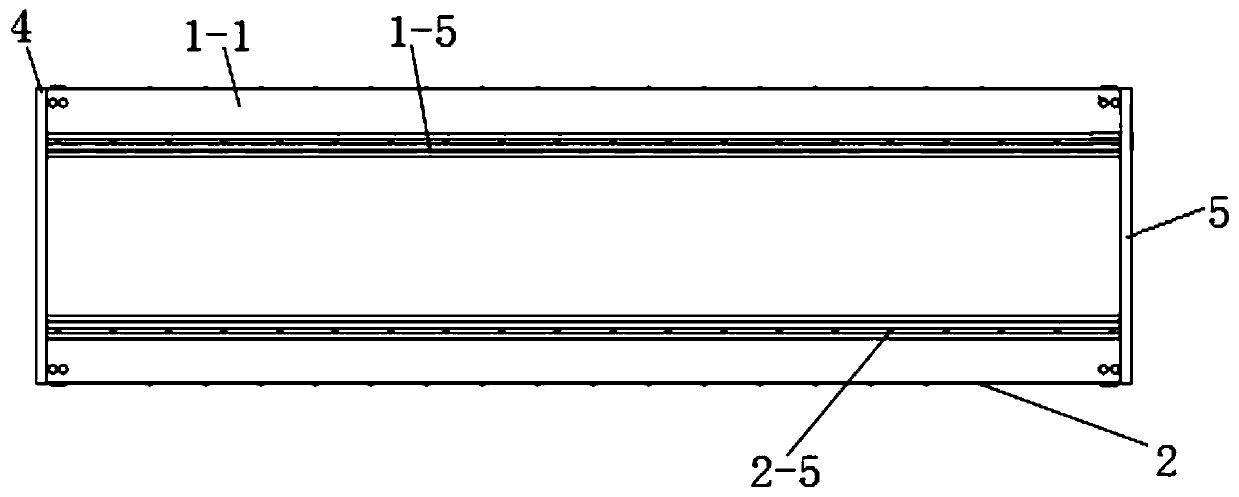

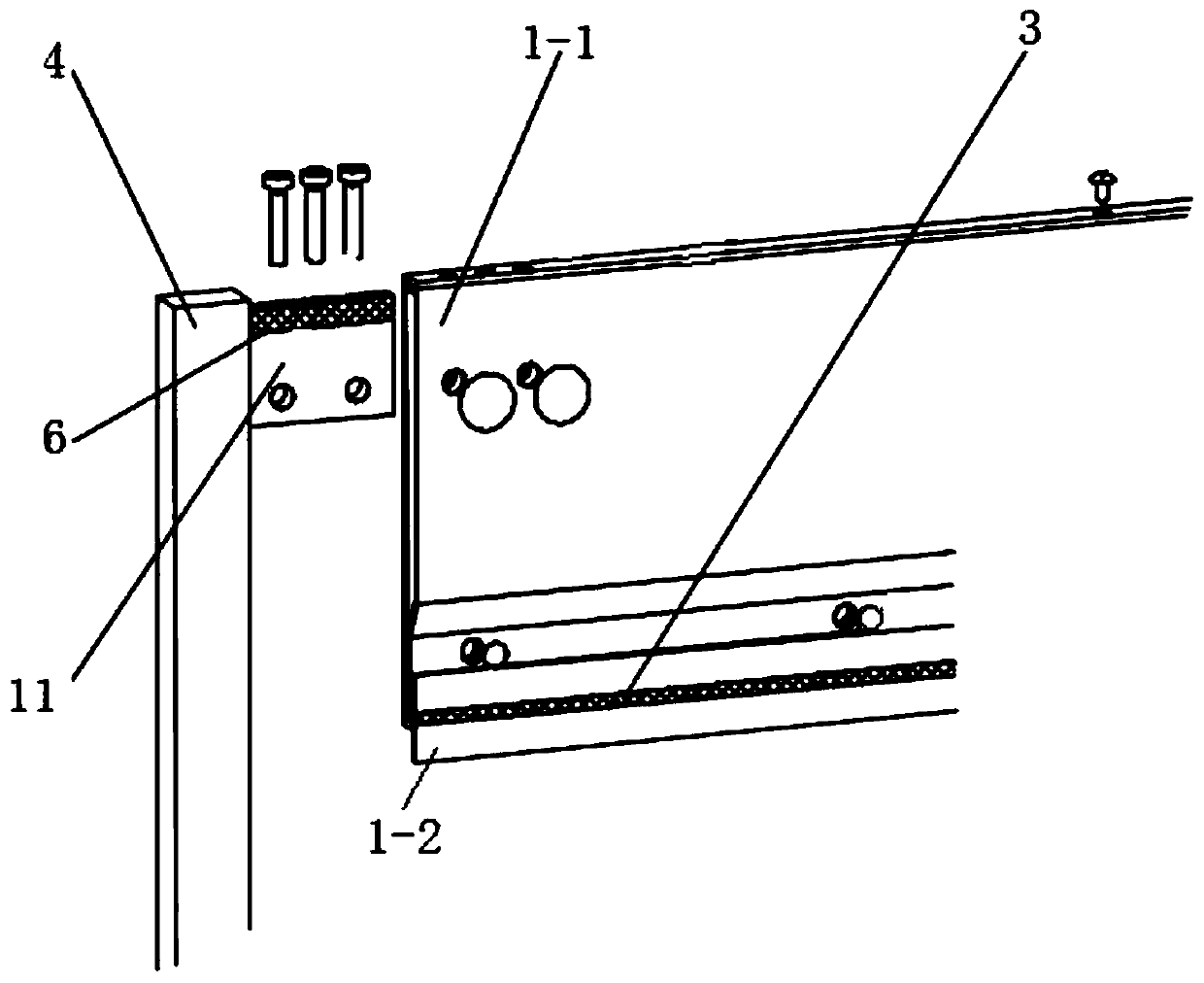

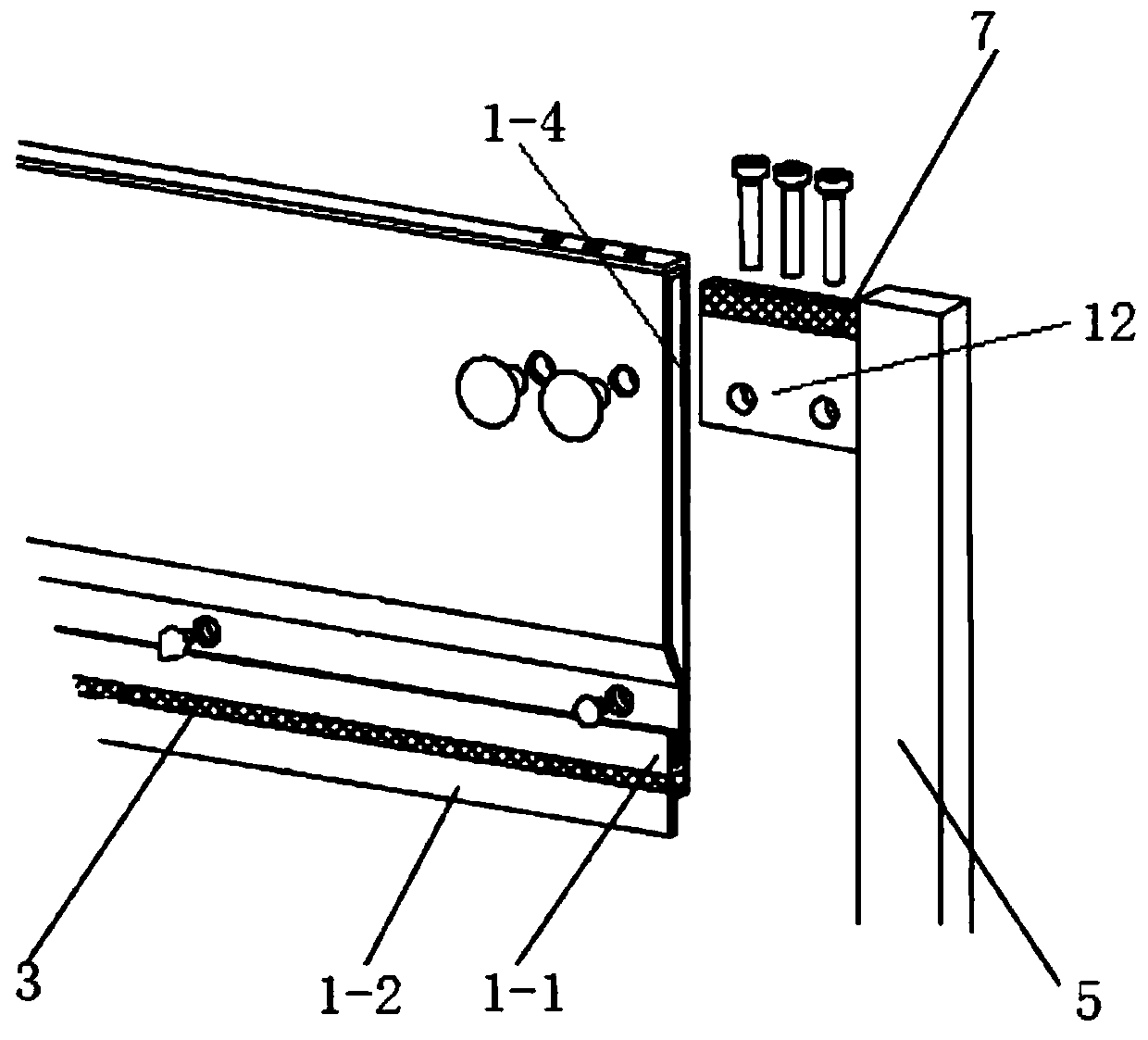

[0032] The present invention is a heald frame with full carbon fiber composite material structure, the structure is as follows figure 1 As shown, it includes an upper beam 1 and a lower beam 2 arranged in parallel, and the upper beam 1 is internally provided with a damping interlayer A3 (see figure 2 ), the two ends of the upper beam 1 are respectively connected to the upper end of the side block A4 and the upper end of the side block B5. Damping interlayer C7 (see image 3 ); the two ends of the lower beam 2 are respectively connected with the lower end of the side block A4 and the lower end of the side block B5, and the connection between the lower cross beam 2 and the side block A4 is provided with a damping interlayer D8 (see Figure 4 ), a damping interlayer E9 is provided at the connection between the lower beam 2 and the side block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com