Casting, pouring method, application of casting method, casting method of automobile wheel, and automobile wheel

A casting method and casting technology, applied in the field of casting, can solve the problems of easy generation of porosity, shrinkage cavity, low qualification rate, long casting cycle, etc. The effect of cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

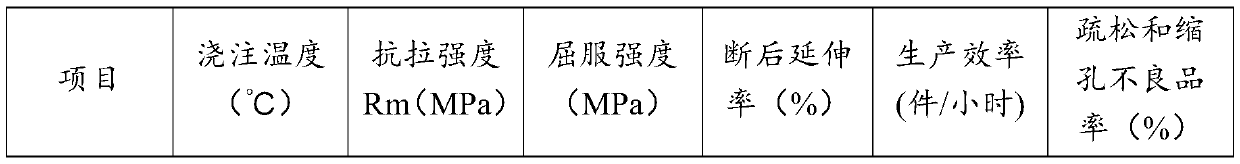

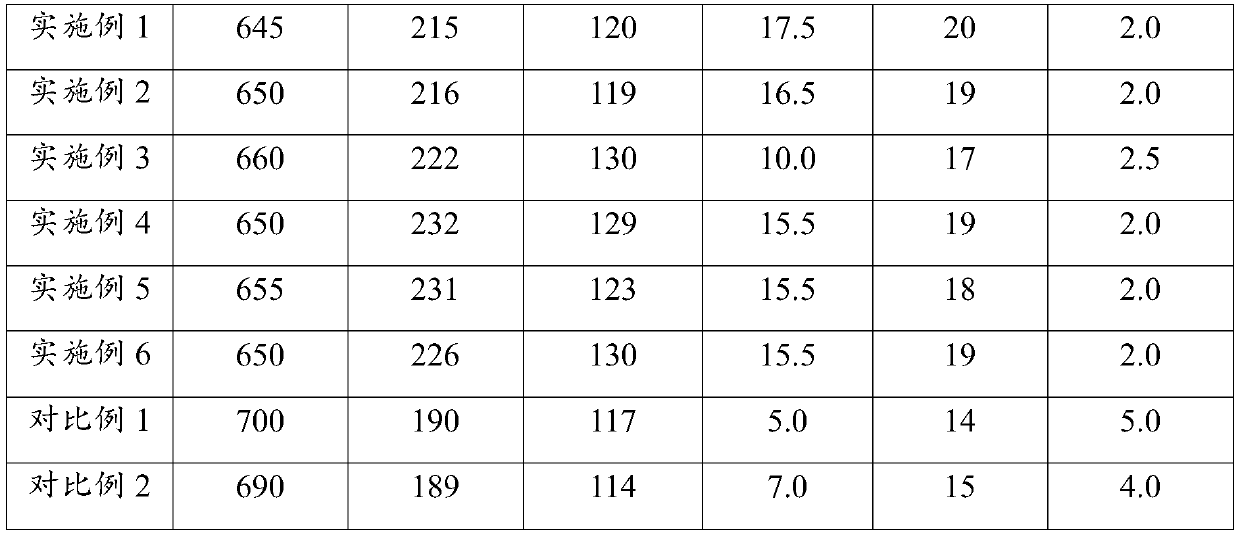

[0083] As a preferred embodiment of the present invention, the pouring method includes the following steps:

[0084] Clamp the mold, lock the mold, inject the alloy liquid into the casting mold cavity at the set temperature, adopt low temperature and low pressure pouring, and set the pouring temperature at 645-660℃. Set the low pressure pouring process parameters, that is, the liquid rise stage. The pressure gradually rises from 0 to 0.018-0.022MPa, and the rise time is 4-8s; in the filling stage, the pressure rises from 0.018-0.022MPa to 0.023-0.027MPa, and the filling time is 10-20s; in the pressurization stage, the pressure is increased from 0.023-0.027MPa rises to 0.08-0.12MPa, pressurization time is 3-8s, and the pressure is maintained continuously, so that the wheel casting is formed and solidified. The pressure holding time is 70-130s, and the pressure is released after the wheel is formed and solidified. The entire pouring process of charging, maintaining and releasing pr...

Embodiment 1

[0101] A casting method for castings, including setting process parameters:

[0102] The pouring temperature is 650℃, the rising pressure is 0.02MPa, the rising time is 6s, the filling pressure is 0.025MPa, the filling time is 10s, the boost pressure is 0.1MPa, and the boost time is 6s;

[0103] After the pressurization is completed, keep it under a pressure of 0.1MPa for 100s, release the pressure and cool down and open the mold.

Embodiment 2

[0105] A casting method for castings, including setting process parameters:

[0106] The pouring temperature is 645℃, the rising pressure is 0.018MPa, the rising time is 4s, the filling pressure is 0.023MPa, the filling time is 10s, the boost pressure is 0.08MPa, and the boost time is 3s;

[0107] After the pressurization is completed, keep it under a pressure of 0.08MPa for 70s, release the pressure and cool down and open the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com