Frequency Tunable Ultrasonic Sensor Array Based on Helmholtz Resonant Cavity

A technology of ultrasonic sensors and acoustic sensors, applied in the field of sensors, can solve problems such as crosstalk, unadjustable frequency, and low efficiency of acoustic-electric energy conversion, and achieve the effect of increasing electrical signals and avoiding crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For a better understanding of the present invention, the following examples are further descriptions of the present invention, but the content of the present invention is not limited to the following examples.

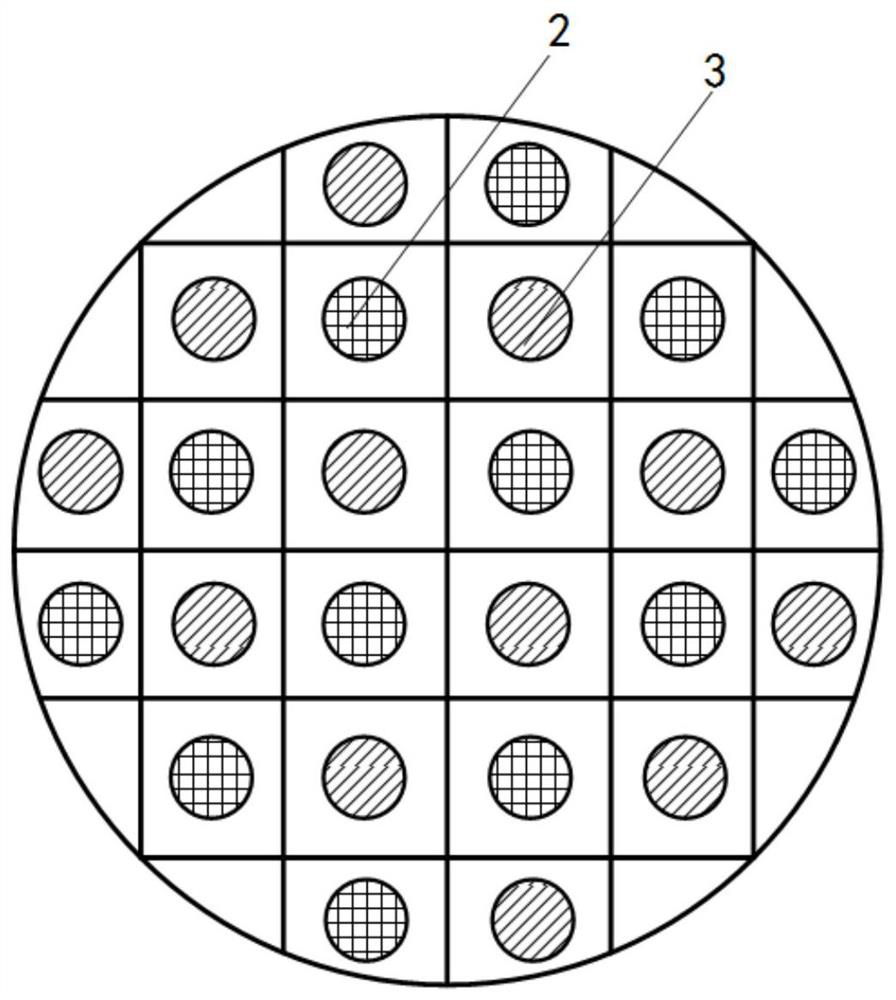

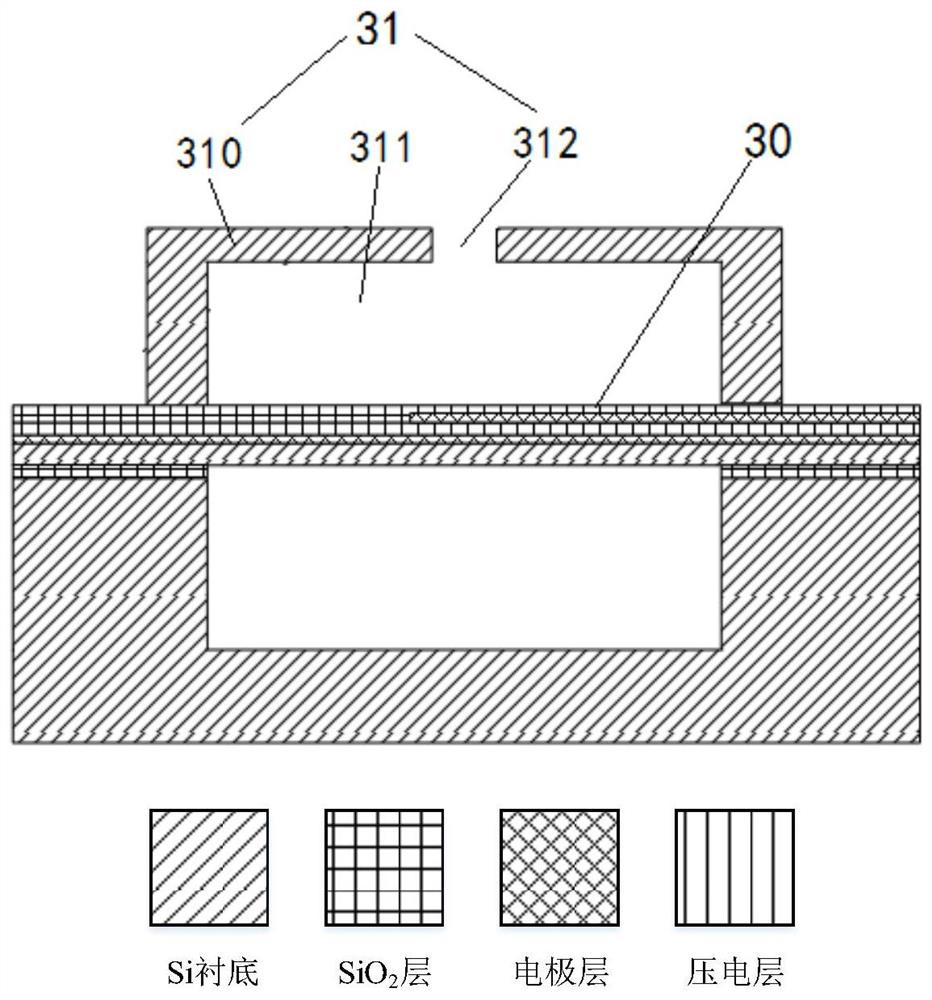

[0026] See figure 1 and figure 2 The present invention provides a frequency-tunable ultrasonic sensor array based on a Helmholtz resonant cavity, which includes a base material 1 , an ultrasonic emitting device 2 and an acoustic wave receiving device 3 arranged on the base material 1 . In this embodiment, the ultrasonic emitting device 2 and the acoustic wave receiving device 3 are arranged on the same chip, and the two can be arranged in any way, and the number, spacing and arrangement of the two can be selected according to specific conditions. The selection of the ultrasonic emitting device 2 is also relatively flexible, and it can be a piezoelectric ultrasonic transducer or a capacitive ultrasonic transducer. The acoustic wave receiving device 3 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com