Electromagnetic-friction power generation water flow power generation device

A technology of friction power generation and water flow power generation, which is applied in the direction of friction generators, electromechanical devices, electrical components, etc., and can solve the problems of low flow speed and inability to be collected and utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

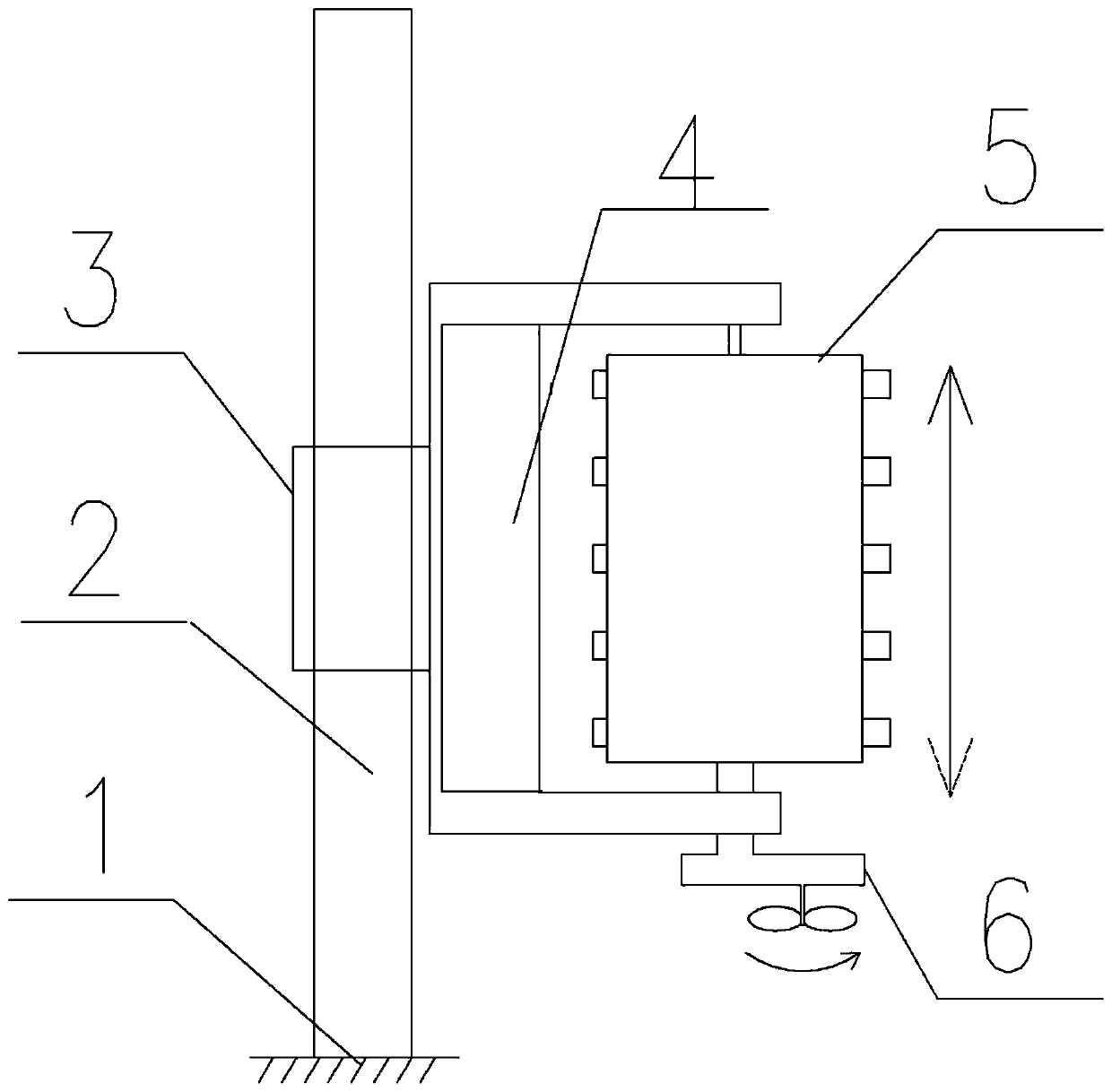

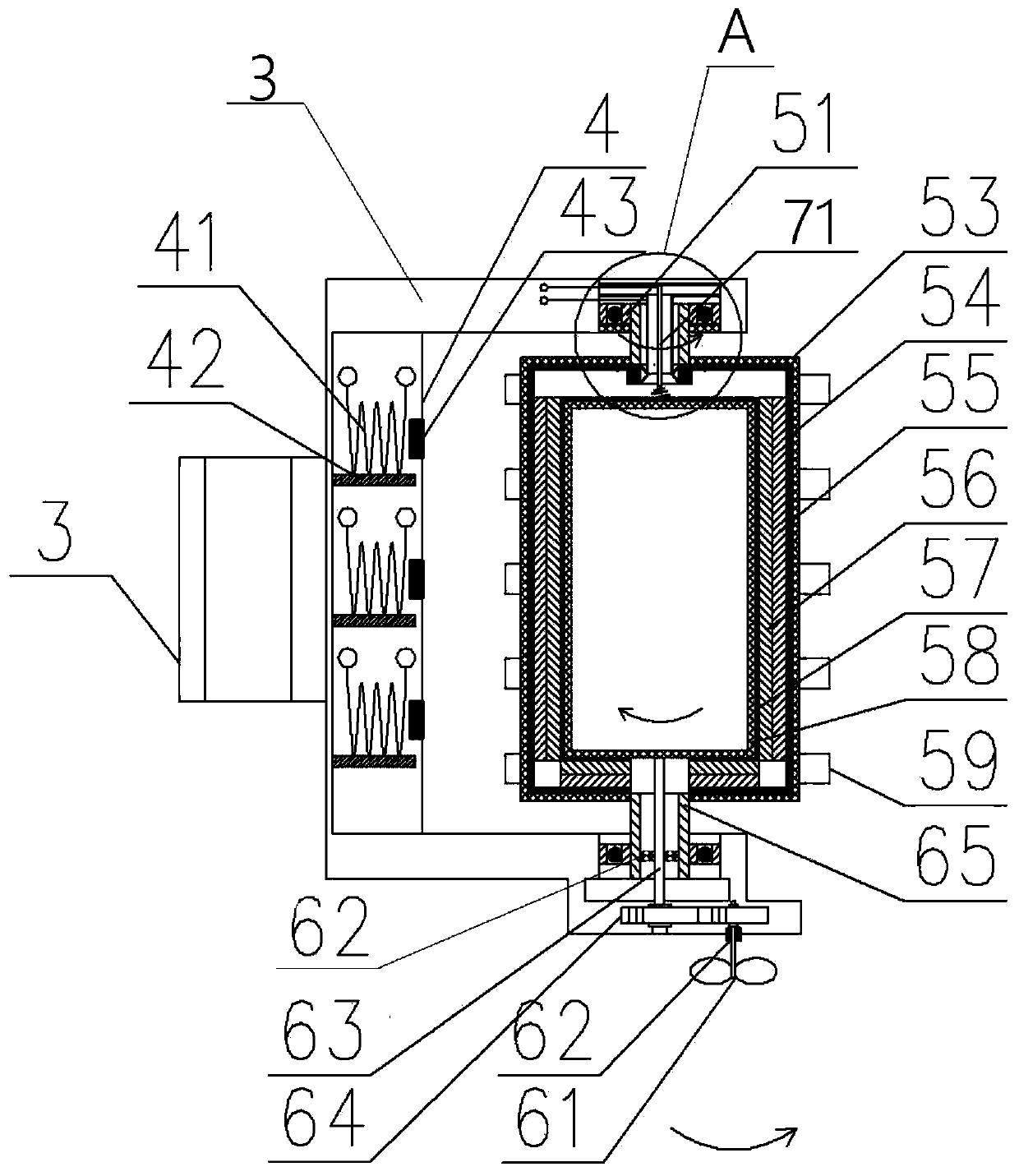

[0024] Such as figure 1 As shown, the embodiment of the technical solution includes a friction power generation system 5, a mechanical energy transmission system 6 and a fixing frame.

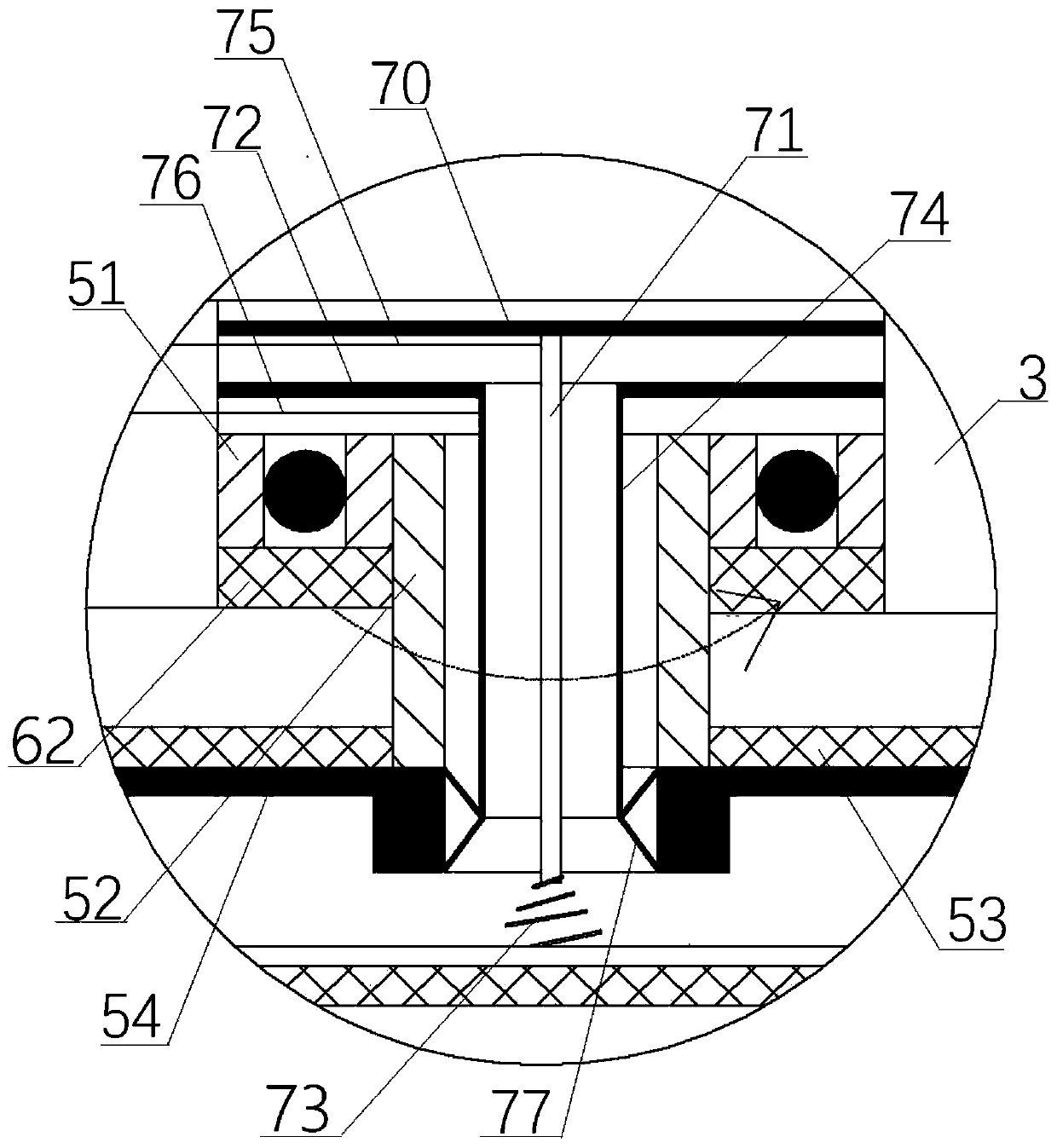

[0025] The triboelectric power generation system 5 includes a first insulating cylinder 53 , a first electrode 54 , a first friction layer 55 , a second friction layer 56 , a second electrode 57 and a second insulating cylinder 58 . The first friction layer and the second friction layer are two kinds of dielectrics with different ability to gain and lose electrons, one is polytetrafluoroethylene, and the other is polyterephthalic acid plastic.

[0026] The first insulating cylinder 53 is arranged on the fixed frame, the fixed frame includes a bracket 3 and a sliding rod 2, the sliding rod 2 is arranged vertically, and the bracket 3 is axially slidably fitted on the sliding rod 2 Above, the first insulating cylinder 53 is rotatably fitted on the bracket 3, and as the water surface changes up an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com