Oxygen-enriched sintering flue gas circulation system and application thereof

A technology of sintering flue gas and circulation system, applied in waste heat treatment, furnace, furnace control device and other directions, can solve the problems of reducing the amount of circulating flue gas, the total amount of gas is limited, and the effect of flue gas emission reduction is deteriorated, so as to ensure the circulation of the flue gas. flow, and the effect of improving the emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

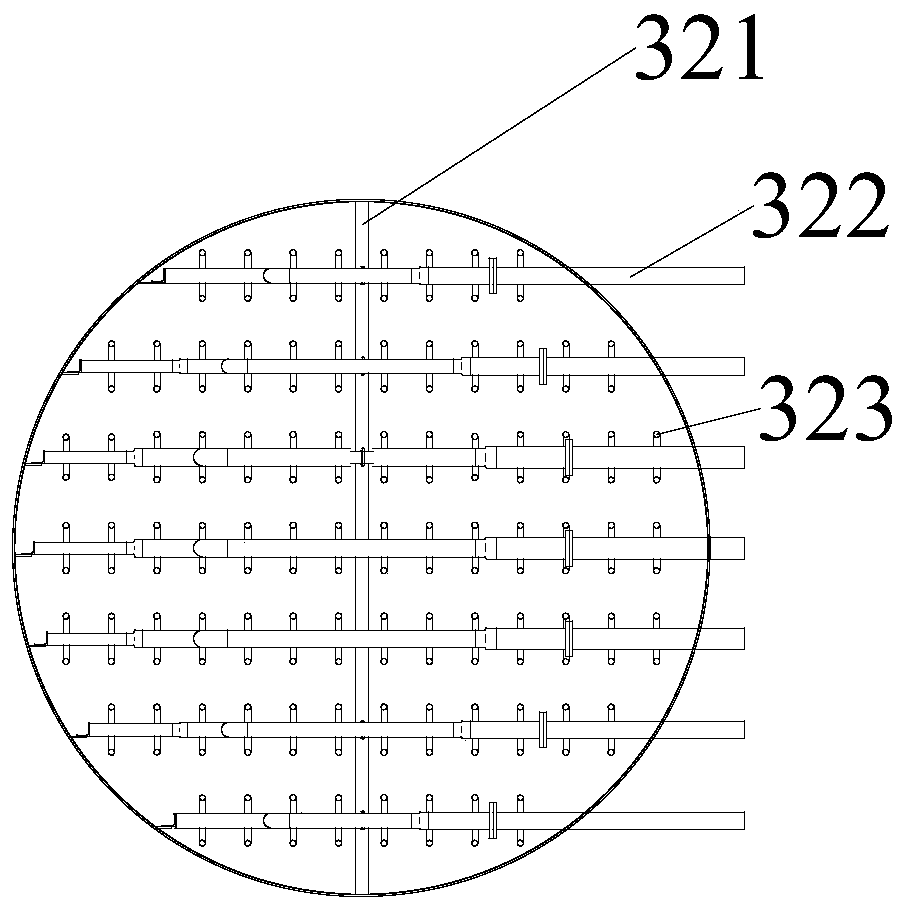

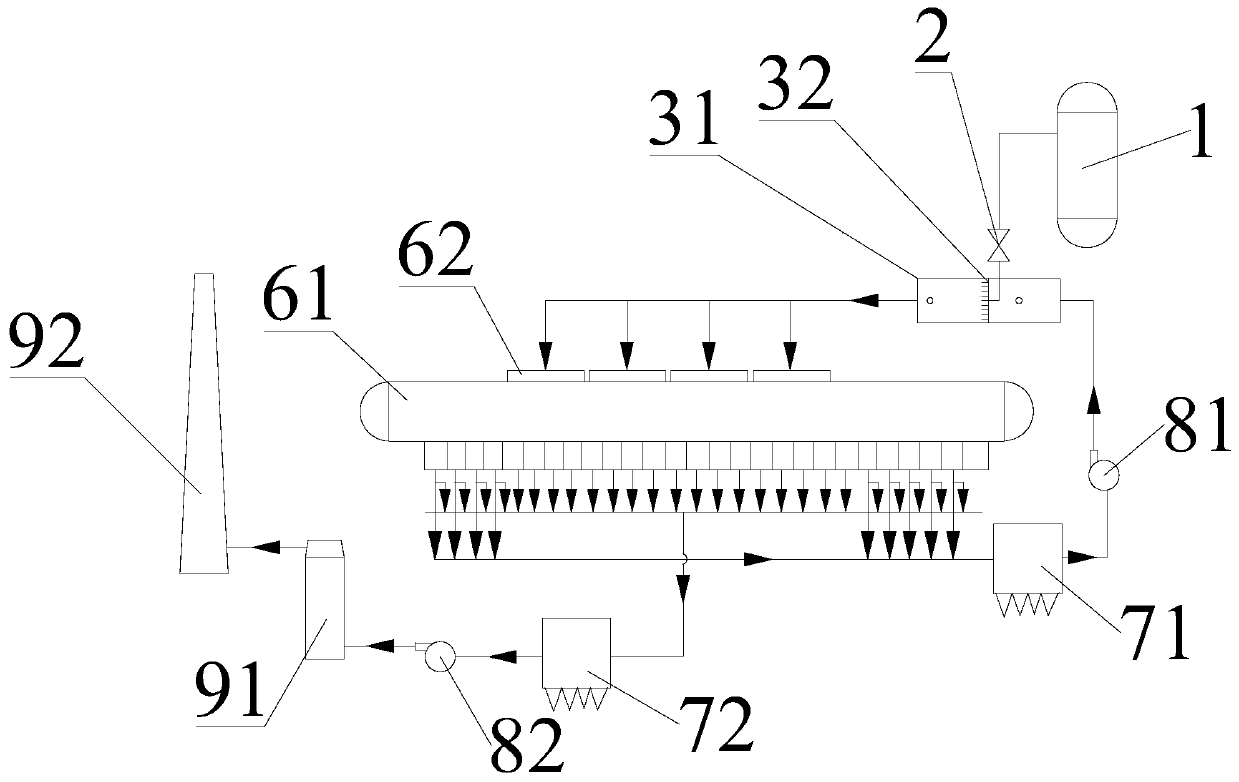

[0067] This embodiment provides an oxygen-enriched sintering flue gas circulation system, and the schematic structural diagram of the oxygen-enriched sintering flue gas circulation system is as follows image 3 As shown, it includes a sintering machine 61 , a first dust collector 71 , a first fan 81 , an oxygen addition system, a second dust collector 72 , a second fan 82 , an absorption tower 91 and a chimney 92 .

[0068] The flue gas outlet of the sintering machine 61 is sequentially connected with the first dust collector 71, the first fan 81 and the oxygen addition system to form a circulation loop.

[0069] The oxygen outlet of the sintering machine 61 is sequentially connected with the second dust collector 72 , the second fan 82 and the post-processing unit to form a flue gas discharge pipeline.

[0070] The surface of the trolley of the sintering machine 61 is covered with a fume sealing cover 62 , and the mixed flue gas discharged from the oxygen addition system ente...

Embodiment 2

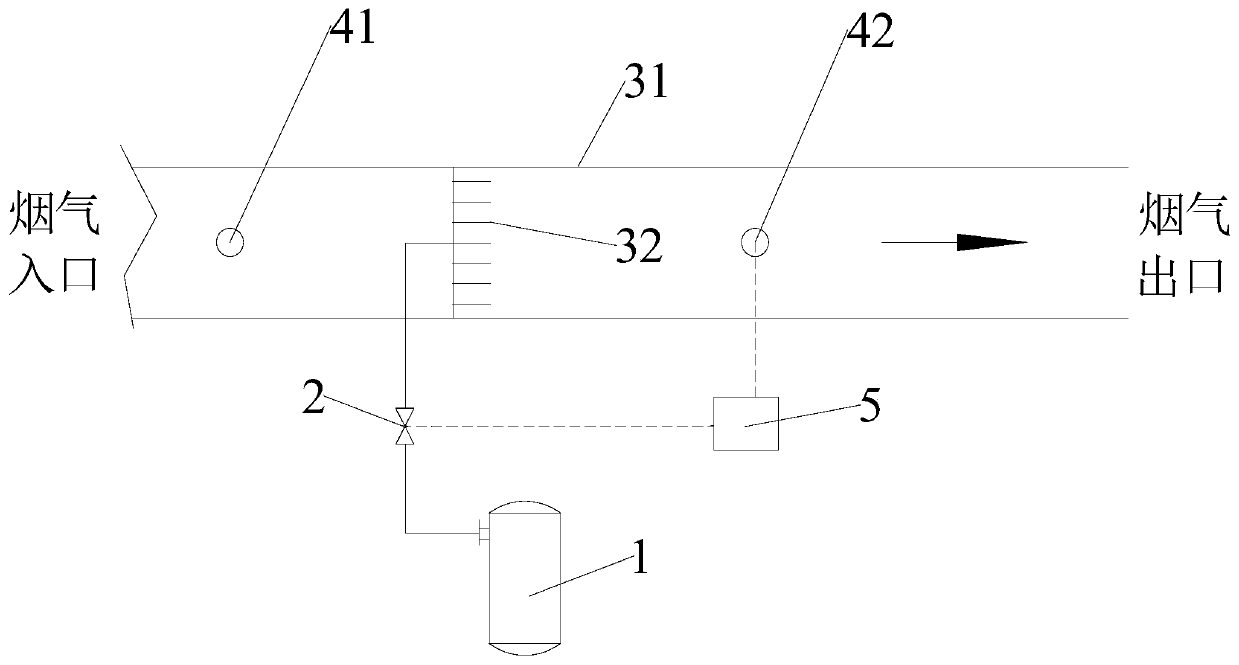

[0079] This embodiment provides an oxygen-enriched sintering flue gas circulation system. In the oxygen-enriched sintering flue gas circulation system, the distance between the first flue gas detection device 41 and the oxygen distribution grid 32 in the oxygen addition device The distance between the second smoke detection device 42 and the oxygen distribution grid 32 is 8m, and the rest are the same as those in Embodiment 1.

Embodiment 3

[0081] This embodiment provides an oxygen-enriched sintering flue gas circulation system. In the oxygen-enriched sintering flue gas circulation system, the distance between the first flue gas detection device 41 and the oxygen distribution grid 32 in the oxygen addition device The distance between the second smoke detection device 42 and the oxygen distribution grid 32 is 1m, and the rest are the same as those in Embodiment 1.

[0082] When using the oxygen-enriched sintering flue gas circulation system provided in Examples 1-3 for sintering flue gas circulation, the following steps are included:

[0083] (1) The flue gas generated in the sintering machine 61 is divided into circulating flue gas and exhaust flue gas. The circulating flue gas accounts for 35-60% of the volume of the flue gas generated in the sintering machine 61. The circulating flue gas flows through the first The dust collector 71 and the first fan 81 flow into the oxygen addition system;

[0084] (2) The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com