Method for reducing content and granularity of metal ions in N-methylpyrrolidone

A technology of methylpyrrolidone and metal ions, applied in the chemical industry, can solve the problems of large waste of materials, difficulty in ensuring the content of metal impurities, unsuitable for production and purification, and achieve the effect of low particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

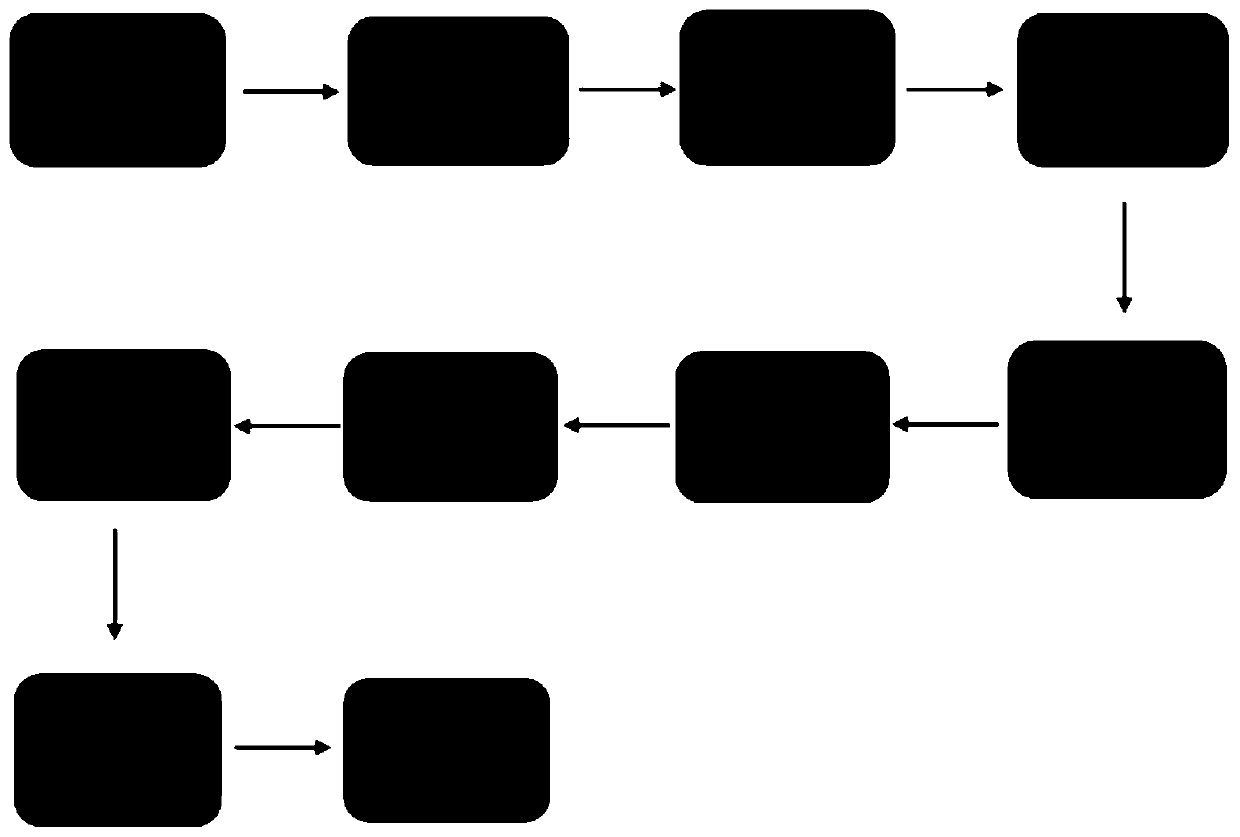

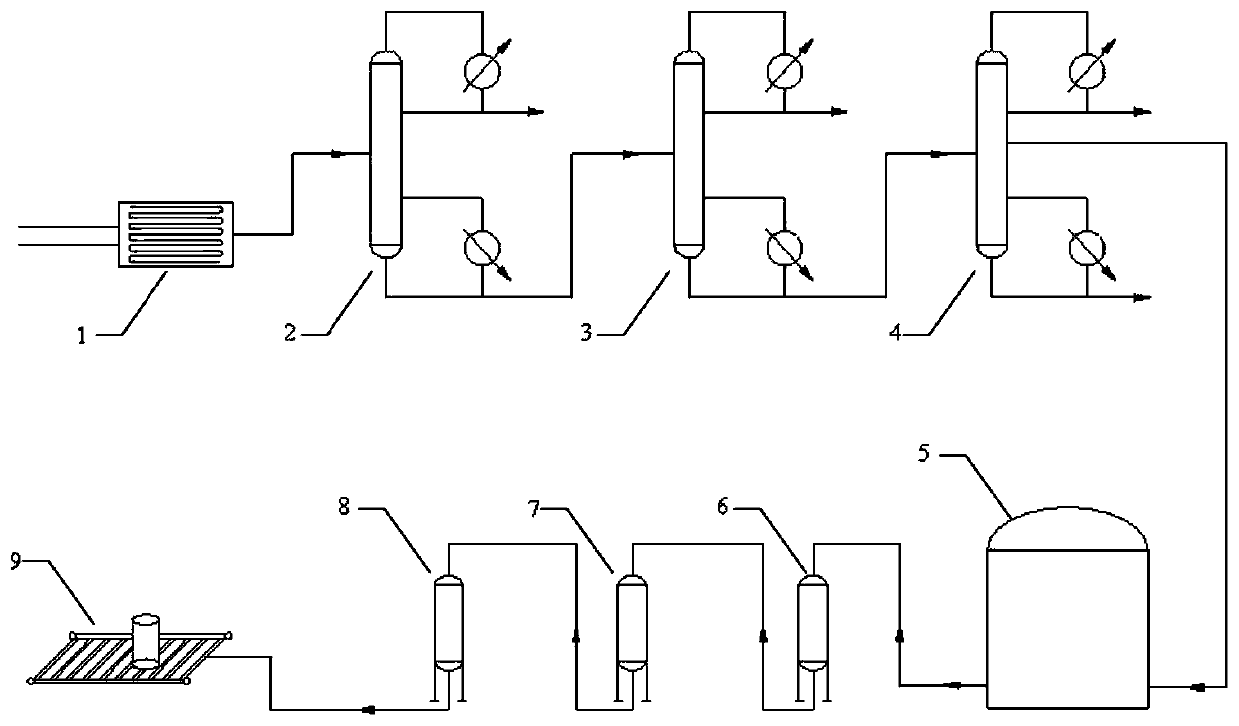

Method used

Image

Examples

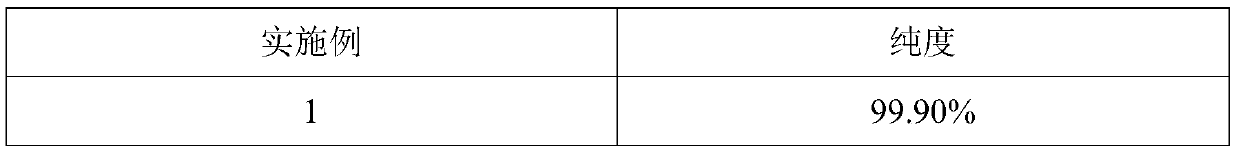

Embodiment 1

[0102] This example provides a method for N-methylpyrrolidone to reduce the content and particle size of metal ions, including the following steps: adding monomethylamine and γ-butyrolactone with a molar ratio of 1:1 to a temperature of 265°C and a pressure of After 1.2 hours of reaction in a 7MPa reactor, the inlet temperature of the crude product obtained by removing water and monomethylamine in an atmospheric column with a temperature of 138°C, a number of trays of 25, a tray height of 5.5m, and a reflux ratio of 0.9 is 128°C, the number of trays is 25, the height of trays is 5.5m, and the reflux ratio is 1. The high boiling point of the rectification tower is 1, and the fine product obtained is filtered by a magnetic field with a magnetic induction intensity of 11000Gs and enters the storage tank. After flowing out of the storage tank, it passes through a primary filter including 15 0.4μm titanium rod filter elements, 15 0.15 The secondary filter of μm polytetrafluoroethyl...

Embodiment 2

[0107] This example provides a method for N-methylpyrrolidone to reduce the metal ion content and particle size, including the following steps: adding monomethylamine and γ-butyrolactone with a molar ratio of 1.1:1 to a temperature of 270°C and a pressure of After reacting in a 9MPa reactor for 2 hours, water and monomethylamine are removed in an atmospheric column with a temperature of 142°C, a plate number of 35, a plate height of 4.5m, and a reflux ratio of 1.1. The obtained crude product enters at a temperature of 132°C, the number of trays is 35, the height of trays is 4.5m, and the reflux ratio is 1.1. The high boiling point of the rectification tower is 1.1, and the fine product obtained is filtered by a magnetic field with a magnetic induction intensity of 13000Gs and then enters the storage tank. After flowing out of the storage tank, it passes through a primary filter including 25 0.5μm titanium rod filter elements, 25 0.25 The secondary filter of μm polytetrafluoroe...

Embodiment 3

[0112] This example provides a method for N-methylpyrrolidone to reduce the content and particle size of metal ions, including the following steps: adding monomethylamine and γ-butyrolactone with a molar ratio of 1:1 to a temperature of 265°C and a pressure of After reacting for 1.5h in the 8MPa reactor, water and monomethylamine are removed in an atmospheric column with a temperature of 140°C, a plate number of 30, a plate height of 5m, and a reflux ratio of 1. The obtained crude product enters at a temperature of 130°C, the number of trays is 30, the height of trays is 5m, and the reflux ratio is 1. The high boiling point is removed from the rectification tower, and the fine product obtained enters the storage tank after being filtered by a magnetic field with a magnetic induction intensity of 12000Gs. After flowing out from the storage tank, it passes through a primary filter including 20 pieces of 0.45μm titanium rod filter elements, and 20 pieces of 0.2μm polymer filter el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com