Leaf fertilizer for preventing and treating camellia oleifera freezing damage

A foliar fertilizer and freezing injury technology, applied in the direction of potash fertilizer, inorganic fertilizer, fertilization device, etc., can solve the problems of few literature reports, unsatisfactory influence on the physiological and biochemical characteristics of oil tea leaves, etc., to improve photosynthesis, increase crop yield and resist Inverse, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

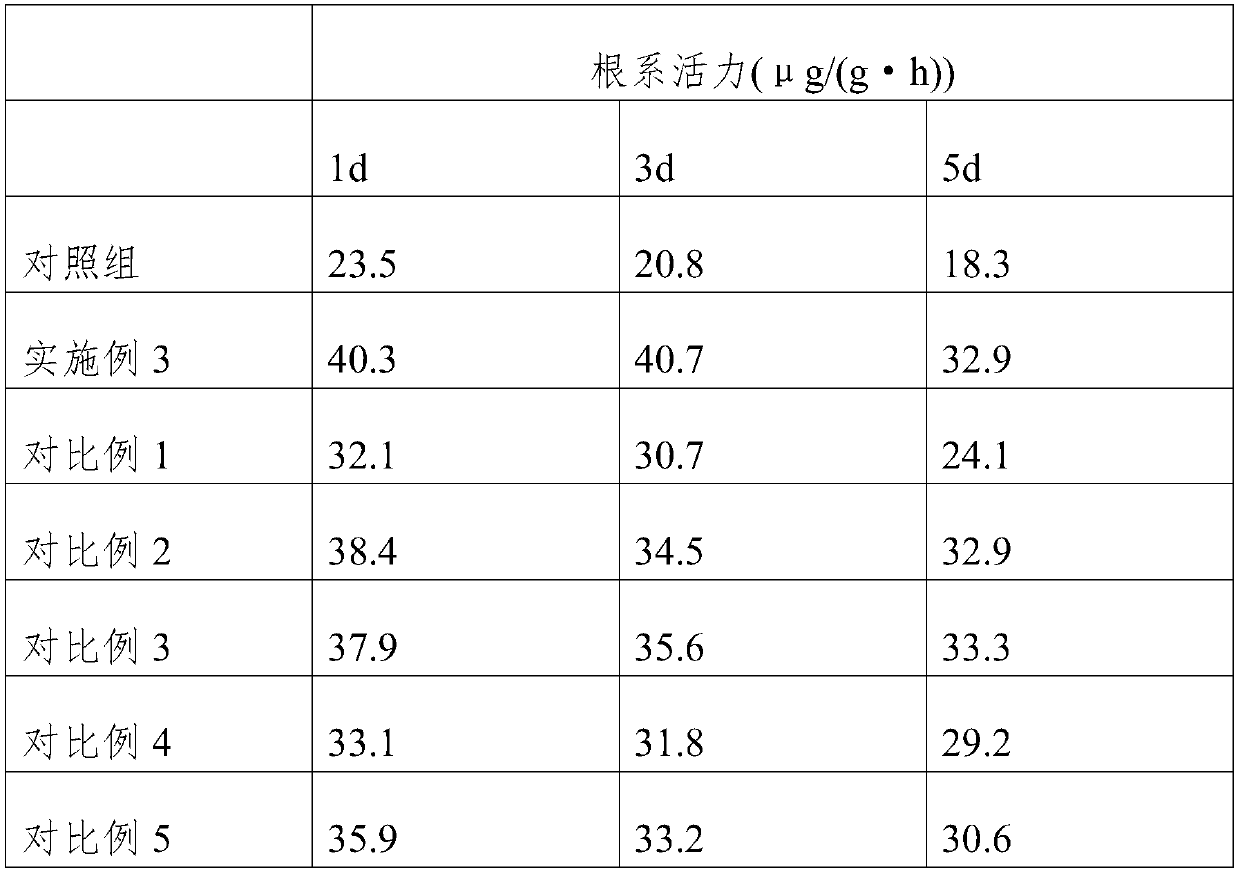

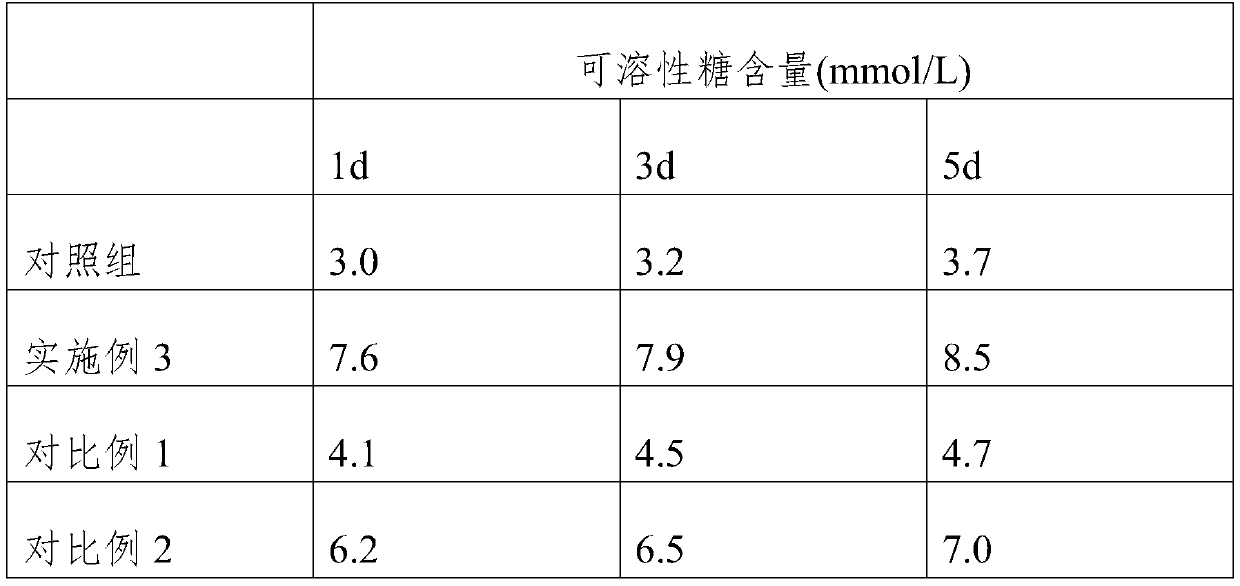

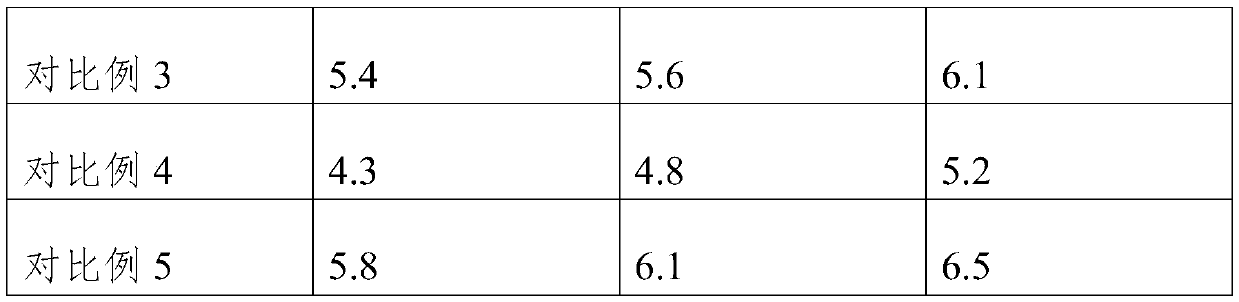

Examples

Embodiment 1

[0029] A foliar fertilizer for preventing and treating freezing damage of camellia oleifera, which is prepared by mixing the following raw materials in parts by weight for 20 minutes at a temperature of 70°C: 40 parts of orange peel liquid, 15 parts of plant ash, 0.8 part of rice bran ash liquid, 0.9 part of bitter vegetable liquid, 6 parts of vermicompost liquid, 50 parts of Dida vegetable liquid;

[0030]The citrus peel liquid is dried at 78°C, crushed, and passed through a 60-mesh sieve to obtain pretreated citrus peel, which is put into a negative pressure tank with a pressure of 0.08Mpa, and returns to normal pressure after maintaining for 30 minutes. Then put the pretreated citrus peels into the NaCl solution, the ratio of solid to liquid is 1:17, and carry out distillation and extraction for 70 minutes to obtain the distilled extract and de-essential citrus peels, and then extract the distilled extract with the extractant for 20 minutes to obtain the extract; The citrus...

Embodiment 2

[0040] A foliar fertilizer for preventing and treating freezing damage of Camellia oleifera, which is prepared by mixing the following raw materials in parts by weight for 15 minutes at a temperature of 60°C: 30 parts of orange peel liquid, 10 parts of plant ash, 0.2 part of rice bran ash liquid, 0.4 part of bitter vegetable liquid, 3 parts of vermicompost liquid, 40 parts of Dida vegetable liquid;

[0041] The citrus peel liquid is dried at 70°C, crushed, passed through a 40-mesh sieve to obtain pretreated citrus peel, put it in a negative pressure tank, set the pressure to 0.02Mpa, and return to normal after 15-min. Then put the pretreated citrus peels into the NaCl solution, the ratio of solid to liquid is 1:10, and carry out distillation and extraction for 50 minutes to obtain the distilled extract and the citrus peels for removing essential oils, and then use the extractant to extract the distilled extract for 15 minutes to obtain the extract ;Put the citrus peel residue ...

Embodiment 3

[0051] A foliar fertilizer for preventing and treating freezing damage of camellia oleifera, which is prepared by mixing the following raw materials in parts by weight for 17 minutes at a temperature of 65°C: 35 parts of orange peel liquid, 13 parts of plant ash, 0.5 part of rice bran ash liquid, 0.6 part of bitter vegetable liquid, 5 parts of vermicompost liquid, 45 parts of Dida vegetable liquid;

[0052] The citrus peel liquid is dried at 75°C, crushed, passed through a 50-mesh sieve to obtain pretreated citrus peel, put it into a negative pressure tank, set the pressure to 0.05Mpa, and return to normal pressure after maintaining for 20 minutes. Then put the pretreated citrus peels into the NaCl solution, the ratio of solid to liquid is 1:13, and carry out distillation and extraction for 60 minutes to obtain the distillation extract and citrus peels for removing essential oils, and then use the extraction agent to extract the distillation extract for 18 minutes to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com