Winding device for textile machine

A technology of textile machinery and equipment, applied in the field of winding equipment for textile machinery, can solve the problems of deviation of textile fabrics, easy wrinkling of textile fabrics, unfavorable normal operation of equipment, etc., and achieves the effect of not easy to wrinkle and improving flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

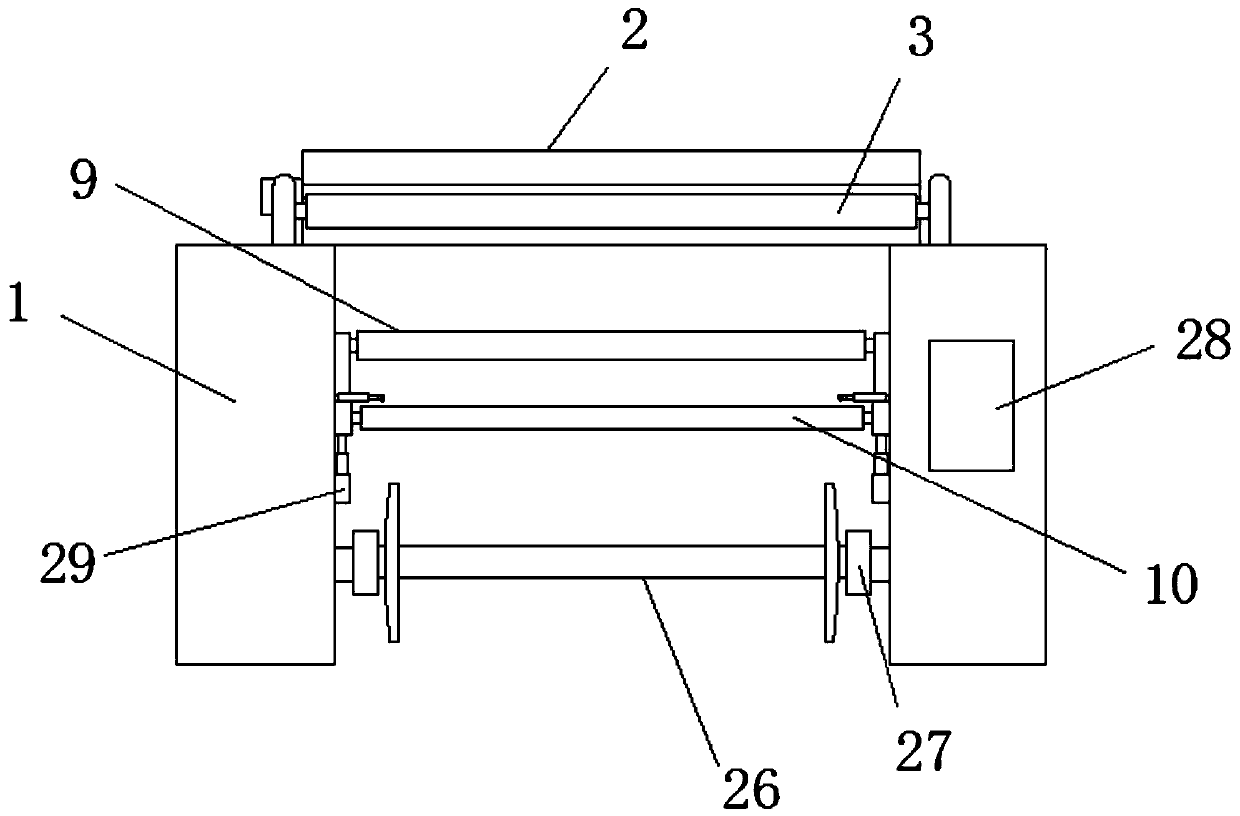

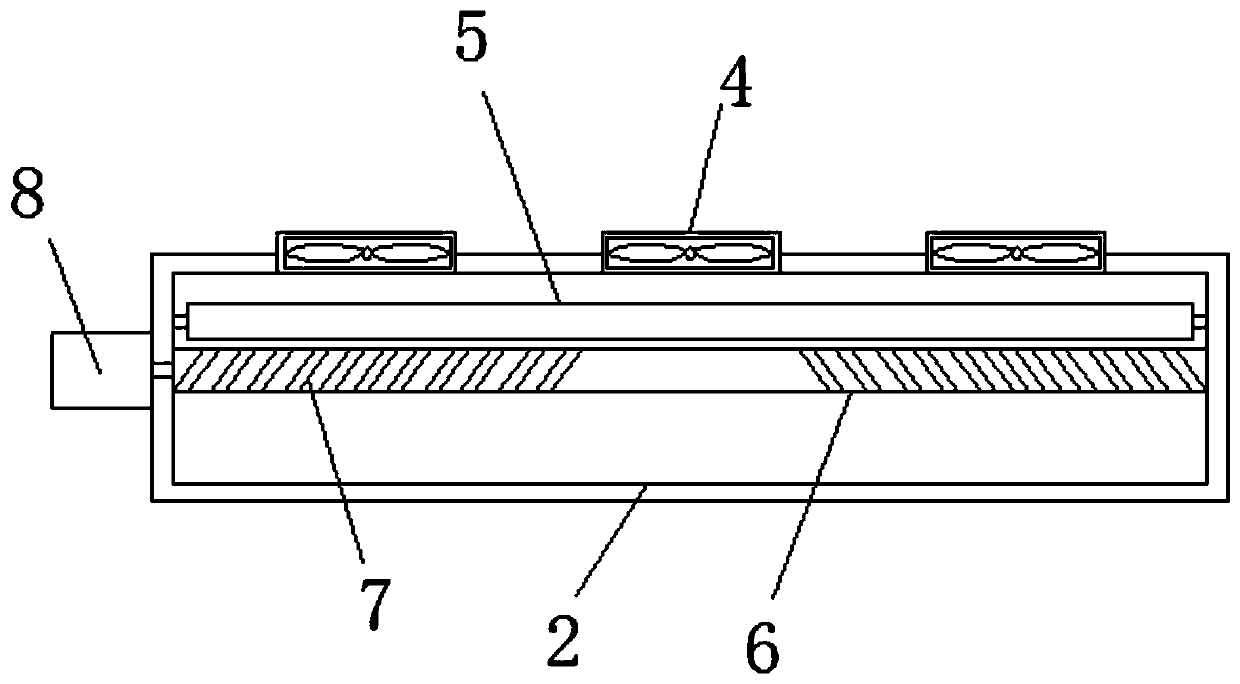

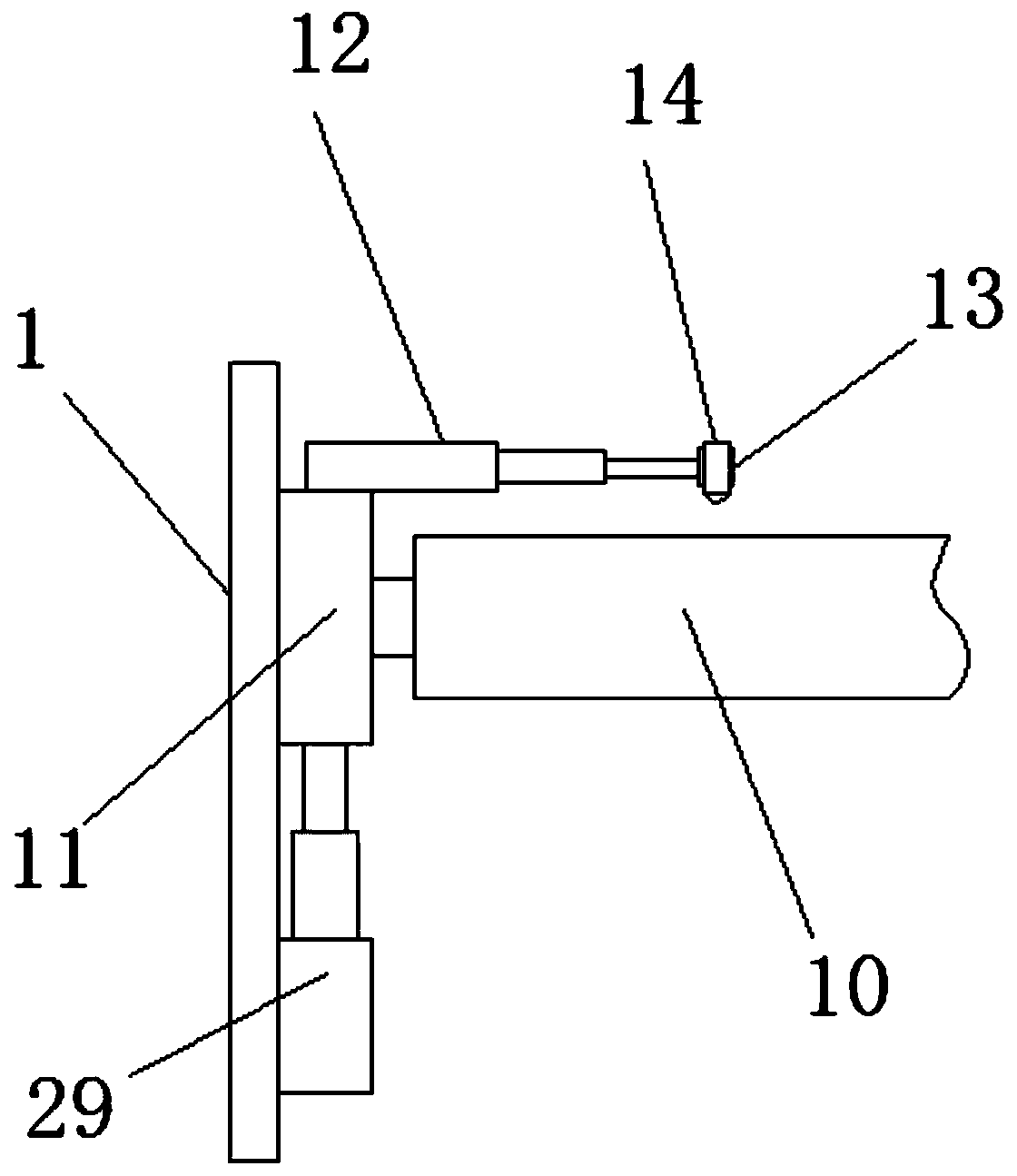

[0028] Such as Figure 1-7 As shown, during work, the winding motor inside the winding frame 1 can be energized through the control panel 28, so that it can drive the winding roller 26 to rotate through the coupling 27, so that the textile cloth can be wound. Wherein, the textile cloth can be well guided by the guide roller 23, so that the textile cloth can enter the inside of the antistatic box 2 smoothly, and the interior of the antistatic box 2 is connected with a traction roller 6, which can pull the cloth. When the traction roller 6 rotates, the helical traction belt 7 arranged oppositely at its two ends can well draw the textile cloth to the two ends of the traction roller 6, thereby effectively improving the smoothness of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com